International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

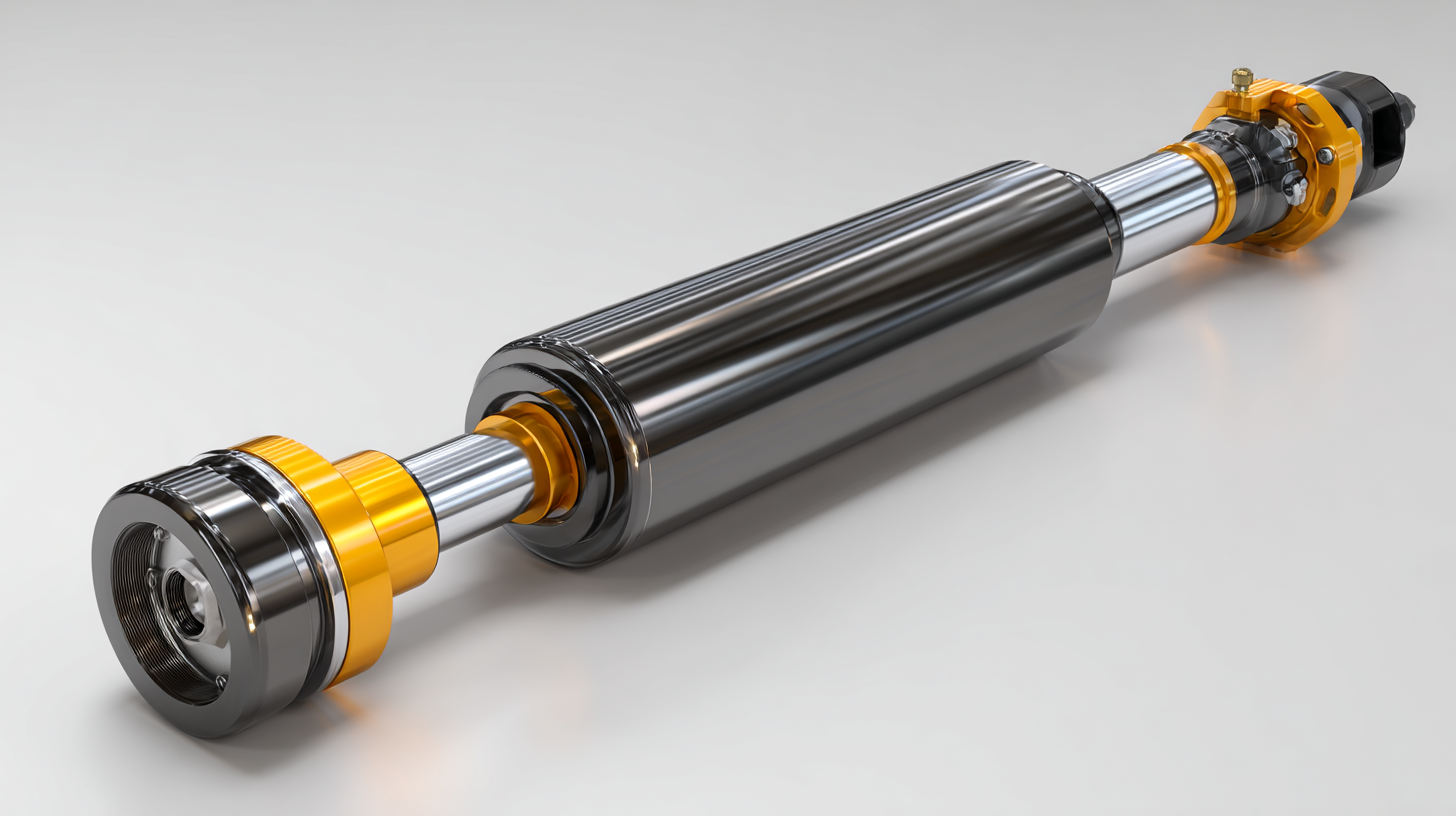

2025 Insights: How Advanced Materials are Revolutionizing the Best Hydraulic Cylinder Industry

In recent years, the hydraulic cylinder industry has undergone significant transformation driven by the advent of advanced materials, which are enhancing performance, durability, and efficiency. According to a report by ResearchAndMarkets, the global hydraulic cylinder market is expected to reach approximately $12 billion by 2025, growing at a CAGR of over 5% from 2020. This growth is largely attributed to advancements in material science that allow for lighter, stronger, and more corrosion-resistant cylinders. Innovations such as carbon-fiber composites and high-strength aluminum alloys are paving the way for hydraulic cylinders that meet the demanding requirements of modern applications, ranging from construction machinery to aerospace systems.

As we delve into the insights for 2025, it is crucial to understand how these advanced materials are not only revolutionizing the hydraulic cylinder industry but also shaping the future of various engineering and industrial applications.

The Impact of Advanced Materials on Hydraulic Cylinder Lifespan and Durability

The advancement of materials science is significantly transforming the hydraulic cylinder industry, particularly with regards to lifespan and durability. Recent reports indicate that the adoption of advanced materials, such as high-strength alloys and composite materials, can extend the lifespan of hydraulic cylinders by up to 30%. For instance, a study conducted by the Hydraulic Institute revealed that cylinders constructed with advanced composite materials exhibit a corrosion resistance that is 100% higher than traditional steel, effectively reducing maintenance costs and downtime.

In addition to improved lifespan, these advanced materials also enhance the overall performance of hydraulic cylinders. For example, research published by the American Society of Mechanical Engineers (ASME) highlighted that cylinders made from lightweight, high-strength materials can operate at pressures up to 15% higher than their conventional counterparts. This not only allows for more efficient operation but also minimizes the weight of hydraulic systems, which can lead to more versatile applications in various industries including construction and aerospace. As companies continue to invest in these innovations, the impact on performance and reliability will only become more pronounced, solidifying the role of advanced materials in the future of hydraulic technologies.

Cost-Benefit Analysis of After-Sales Services in the Hydraulic Cylinder Sector

In the rapidly evolving hydraulic cylinder sector, after-sales services have emerged as a critical component in enhancing customer satisfaction and loyalty. A cost-benefit analysis reveals that investing in comprehensive after-sales support can yield significant returns for manufacturers. By offering services such as regular maintenance, prompt repairs, and technical assistance, companies not only address immediate customer needs but also foster long-term relationships that can lead to repeat business. This proactive approach helps in minimizing downtime for clients, ultimately enhancing their operational efficiency and reducing overall costs.

Furthermore, the incorporation of advanced materials in hydraulic cylinder manufacturing has underscored the importance of after-sales expertise. With the introduction of high-performance alloys and composites, customers require informed guidance on the maintenance and longevity of their hydraulic systems. By providing tailored after-sales solutions, manufacturers can differentiate themselves in a competitive market. This strategic focus not only improves customer retention but also positions companies as leaders in innovation, ensuring that they remain at the forefront of the industry’s evolution. Thus, a well-crafted after-sales service strategy not only enhances operational performance for clients but also solidifies a manufacturer’s market position.

Maintenance Trends: How New Materials are Reducing Repair Costs in Hydraulic Systems

The hydraulic cylinder industry is experiencing significant transformations, largely driven by the advent of advanced materials that are reshaping maintenance practices. As new materials are introduced, they bring enhanced durability and resistance to wear and corrosion, ultimately leading to reduced repair costs. This shift is crucial for operators seeking to minimize downtime and improve overall performance in hydraulic systems.

Tips: Regularly inspect hydraulic cylinders for signs of wear and tear. Early detection of potential issues can prevent costly repairs down the line. Additionally, investing in training for maintenance staff on the latest materials can help them understand the best practices for extending the lifespan of hydraulic systems.

As we look toward the future, innovations such as smart sensors are set to revolutionize maintenance approaches. These sensors can provide real-time data monitoring, which greatly contributes to proactive maintenance strategies. Companies that adopt these technologies will not only optimize their operations but also enhance the efficiency of hydraulic systems significantly.

Tips: Consider implementing a comprehensive training program focused on new technologies. This will empower your maintenance team to leverage smart sensors effectively, ensuring your hydraulic systems operate at peak performance.

Real-World Case Studies: Innovative Solutions Enhancing Hydraulic Cylinder Performance

In the evolving landscape of hydraulic cylinder technology, innovative materials are playing a crucial role in enhancing performance and durability. Recent studies indicate that the introduction of advanced composites and high-strength alloys can lead to significant improvements in fatigue resistance and weight reduction. For instance, a report by the Hydraulic Institute highlights that using lightweight materials can decrease overall energy consumption in operations by up to 30%, substantially improving system efficiency.

Real-world case studies underscore these advancements. For example, a recent implementation at a major construction firm showcased a new hydraulic cylinder made from advanced thermoplastic composites. The results revealed a 25% increase in operational lifespan and a 20% reduction in maintenance costs compared to traditional metal cylinders. Additionally, the use of smart sensor integration in hydraulic systems has proven to optimize performance by providing real-time feedback and predictive maintenance data. Such innovations not only enhance performance but also contribute to a more sustainable operational framework within the hydraulic industry.

Future Projections: The Role of R&D in Hydraulic Cylinder Technology Advancement

In recent years, the hydraulic cylinder industry has witnessed a significant shift, driven by advancements in materials and technology. The global hydraulic cylinder market, valued at $10.94 billion in 2018, is projected to reach $19.77 billion by 2032, growing at a compound annual growth rate of 4%. This growth is largely attributed to increased applications across various sectors, such as construction, agriculture, and manufacturing, which demand more efficient and durable hydraulic systems.

Research and development (R&D) play a pivotal role in this evolution, focusing on the creation of advanced materials that enhance performance and reliability. Innovations in lightweight composites, for instance, not only reduce the weight of hydraulic cylinders but also improve their resistance to wear and corrosion. This ongoing investment in R&D ensures that manufacturers can meet the rising demands for sustainability and efficiency, ultimately leading to more robust and cost-effective hydraulic solutions for diverse industries. As R&D continues to drive advancements, the hydraulic cylinder industry stands at the forefront of technological innovation, promising a future with increased capabilities and applications.

2025 Insights: Advanced Materials in Hydraulic Cylinder Industry

This chart illustrates the projected advancements in hydraulic cylinder technology due to the incorporation of advanced materials. As R&D efforts intensify, we expect significant improvements in several key performance metrics over the next few years.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.