International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

What Are the Key Benefits of Using Hydraulic Cylinder Tools in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the integration of advanced technologies is essential for enhancing efficiency and productivity. One such innovation, Hydraulic Cylinder Tools, has become increasingly vital across various sectors. According to a report by MarketsandMarkets, the global hydraulic tools market is projected to reach $14.5 billion by 2026, growing at a CAGR of 5.2%. This surge is driven by the escalating demand for automated systems, which necessitate the adoption of reliable hydraulic machinery to meet stringent operational demands and improve overall performance.

The versatility and power of Hydraulic Cylinder Tools offer manufacturers significant advantages, such as increased precision in machining processes and enhanced safety measures during operation. A survey conducted by the Manufacturing Institute indicates that companies utilizing hydraulic tools experience a 30% reduction in production time and a 20% decrease in operational costs. These benefits underscore the importance of incorporating hydraulic technology into manufacturing practices, positioning organizations at the forefront of innovation and productivity in an increasingly competitive market.

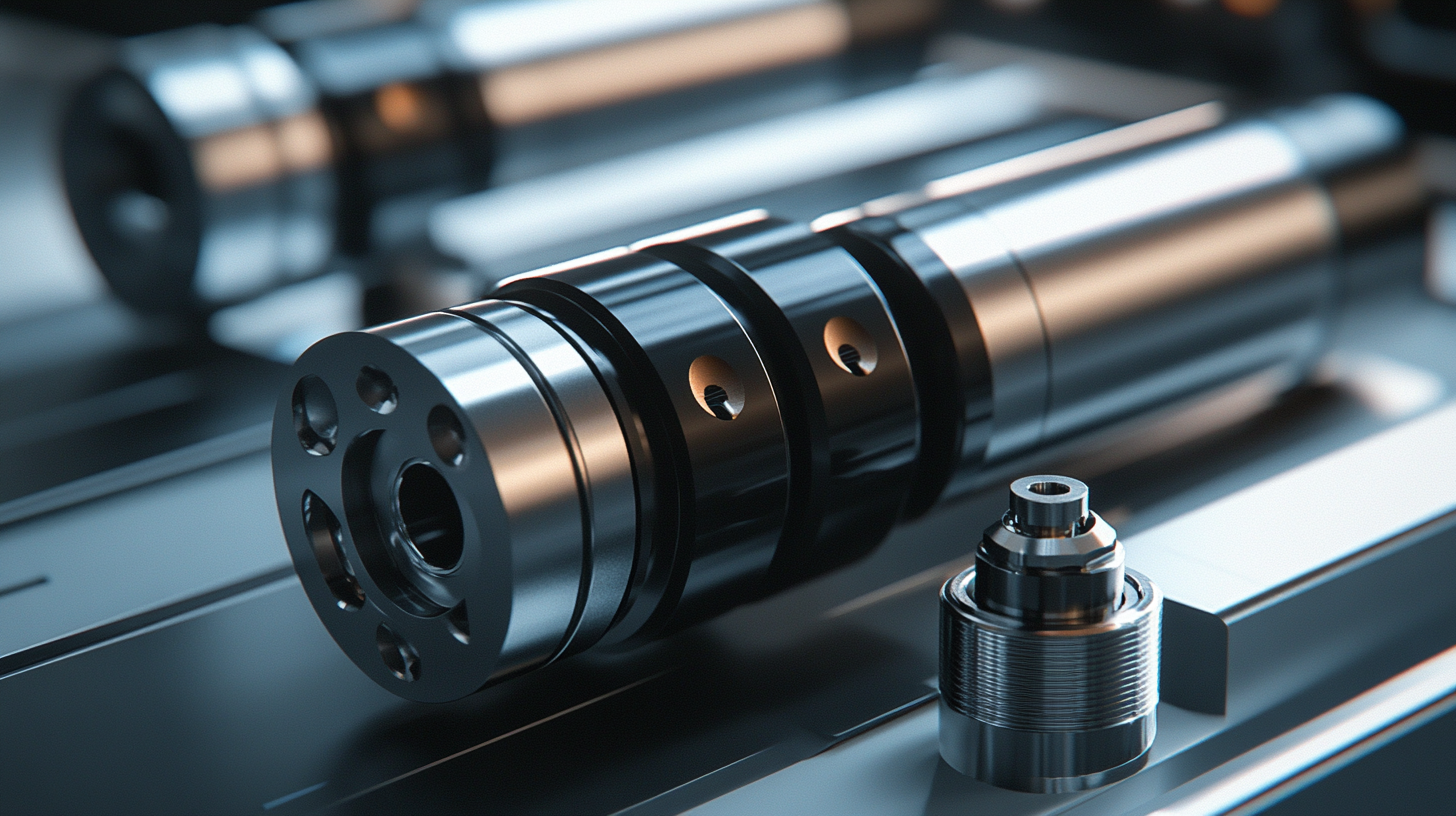

Understanding Hydraulic Cylinder Tools and Their Role in Manufacturing

Hydraulic cylinder tools are pivotal in modern manufacturing, playing a crucial role in enhancing productivity and efficiency. These tools utilize pressurized hydraulic fluid to generate force, enabling machinery to perform heavy lifting and precise movements. According to a report by Grand View Research, the global hydraulic cylinder market was valued at approximately $12.5 billion in 2022 and is projected to grow, reflecting the increasing reliance on automation and heavy machinery in manufacturing processes. One of the primary advantages of hydraulic cylinder tools is their ability to exert significant force while maintaining control over complex tasks. This precision is essential in industries such as automotive and aerospace manufacturing, where exact tolerances are necessary. The U.S. Bureau of Labor Statistics notes that advanced manufacturing sectors, which often integrate hydraulic systems, contribute over $2 trillion to the nation's economy, highlighting their importance in maintaining competitiveness in today’s market. Furthermore, hydraulic systems are generally more energy-efficient compared to other mechanical systems. The National Fluid Power Association indicates that hydraulic systems can deliver up to 90% energy efficiency, a critical factor as industries increasingly strive for sustainability. As manufacturers focus on reducing their carbon footprint and operational costs, hydraulic cylinder tools emerge as a viable solution, combining strength, efficiency, and reliability.

Improving Efficiency and Productivity with Hydraulic Cylinder Tools

In today’s competitive manufacturing landscape, the integration of hydraulic cylinder tools has become instrumental in driving efficiency and productivity. According to a recent report by the Manufacturing Institute, companies that leverage advanced hydraulic technology can see productivity improvements of up to 25%. This enhancement is largely attributed to the reliability and power these tools provide, allowing manufacturers to streamline operations and reduce downtime.

Hydraulic cylinder tools significantly improve the speed of various manufacturing processes. A study published by the International Journal of Advanced Manufacturing Technology reveals that hydraulic systems can complete tasks in half the time compared to mechanical systems. This acceleration in production cycles not only reduces lead times but also increases the output, aligning with customer demands in a just-in-time manufacturing environment.

Moreover, the adaptability of hydraulic cylinder tools plays a crucial role in catering to the evolving needs of modern manufacturing. A survey from Statista indicates that over 70% of manufacturers are looking to implement flexible automation solutions. Hydraulic tools can easily be integrated into existing setups, providing manufacturers with the ability to modify their operations without significant capital investment, ultimately leading to enhanced operational agility and cost savings.

Enhancing Safety Standards in the Workplace with Hydraulic Technology

Hydraulic technology has become a cornerstone of modern manufacturing, significantly enhancing safety standards in the workplace. One of the most notable advantages of hydraulic cylinder tools is their ability to exert large amounts of force with precision, reducing the risk of accidents caused by human error. By mechanizing tasks that require significant lifting, pushing, or pulling, hydraulic tools minimize the physical strain on workers and help prevent injuries related to heavy lifting or awkward postures.

Another critical aspect of using hydraulic cylinder tools is their capacity for automation. When integrated into manufacturing processes, these tools can operate with consistent force and repeatability, ensuring that operations are carried out with minimal deviation. This not only leads to better product quality but also fosters a safer environment, as the predictability of hydraulic systems helps reduce the chances of unexpected equipment failures or operational mishaps. Enhanced safety protocols can be established as workers can rely on these systems to perform high-risk tasks, allowing them to focus on monitoring and maintaining equipment rather than performing dangerous manual operations.

Furthermore, the incorporation of hydraulic technology facilitates better workplace design. By utilizing hydraulic systems, manufacturers can create streamlined workflows that reduce clutter and minimize hazards. With carefully designed layouts incorporating hydraulic cylinder tools, workplaces can be organized to prioritize safety, leading to a significant decrease in workplace accidents. The transition to hydraulic solutions not only improves the efficiency of manufacturing processes but also cultivates a culture of safety that is essential in today's industrial sectors.

Cost Savings and Maintenance Benefits of Hydraulic Cylinder Tools

In modern manufacturing, the integration of hydraulic cylinder tools has proven to be a game-changer, particularly when it comes to cost savings and maintenance benefits. These advanced tools are designed to maximize efficiency while minimizing operational costs. One of the most significant financial advantages of hydraulic cylinder tools lies in their ability to automate processes that would otherwise require extensive manual labor. By reducing the need for human intervention, companies can cut down on labor costs and increase productivity simultaneously.

Furthermore, hydraulic cylinder tools typically require less maintenance compared to traditional mechanical systems. Their design minimizes wear and tear, allowing them to operate for extended periods without significant issues. This reliability not only decreases downtime but also reduces maintenance expenses. Manufacturers find that with fewer breakdowns and less frequent repairs, the overall cost of ownership for hydraulic systems is notably lower.

Additionally, these tools provide a level of precision and power that enhances the quality of the work being performed. This precision means fewer errors and rework, further contributing to cost efficiency. In an industry where margins can be tight, the cumulative effect of these benefits can significantly improve a manufacturer’s bottom line. By leveraging hydraulic cylinder tools, companies can not only save on immediate costs but also invest in long-term operational sustainability.

Applications of Hydraulic Cylinder Tools Across Various Industries

Hydraulic cylinder tools have become indispensable in various industries, revolutionizing manufacturing processes through their exceptional strength and versatility. One of the primary applications of these tools is in construction, where they are utilized for heavy lifting and precise positioning of structural components. This capability not only enhances efficiency but also improves safety on job sites, allowing for reliable operation under extreme conditions.

In the automotive industry, hydraulic cylinders play a crucial role in assembly lines and maintenance tasks. They are essential for effortlessly lifting vehicles during repairs and ensuring accurate manipulation of parts. Furthermore, the aerospace sector benefits from hydraulic cylinder tools in aircraft assembly and testing, where precision is paramount. With a projected global market growth from USD 14.3 billion in 2021 to USD 18.3 billion by 2027, the demand for these tools reflects their increasing importance in modern manufacturing landscapes.

Additionally, hydraulic cylinders are widely used in agriculture for the operation of machinery, enabling the efficient farming of crops. These tools ensure that various agricultural equipment, from plows to harvesters, operates smoothly, enhancing productivity and reducing labor costs. As industries continue to evolve, the applications of hydraulic cylinder tools will expand, solidifying their status as vital assets in advanced manufacturing solutions.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.