International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

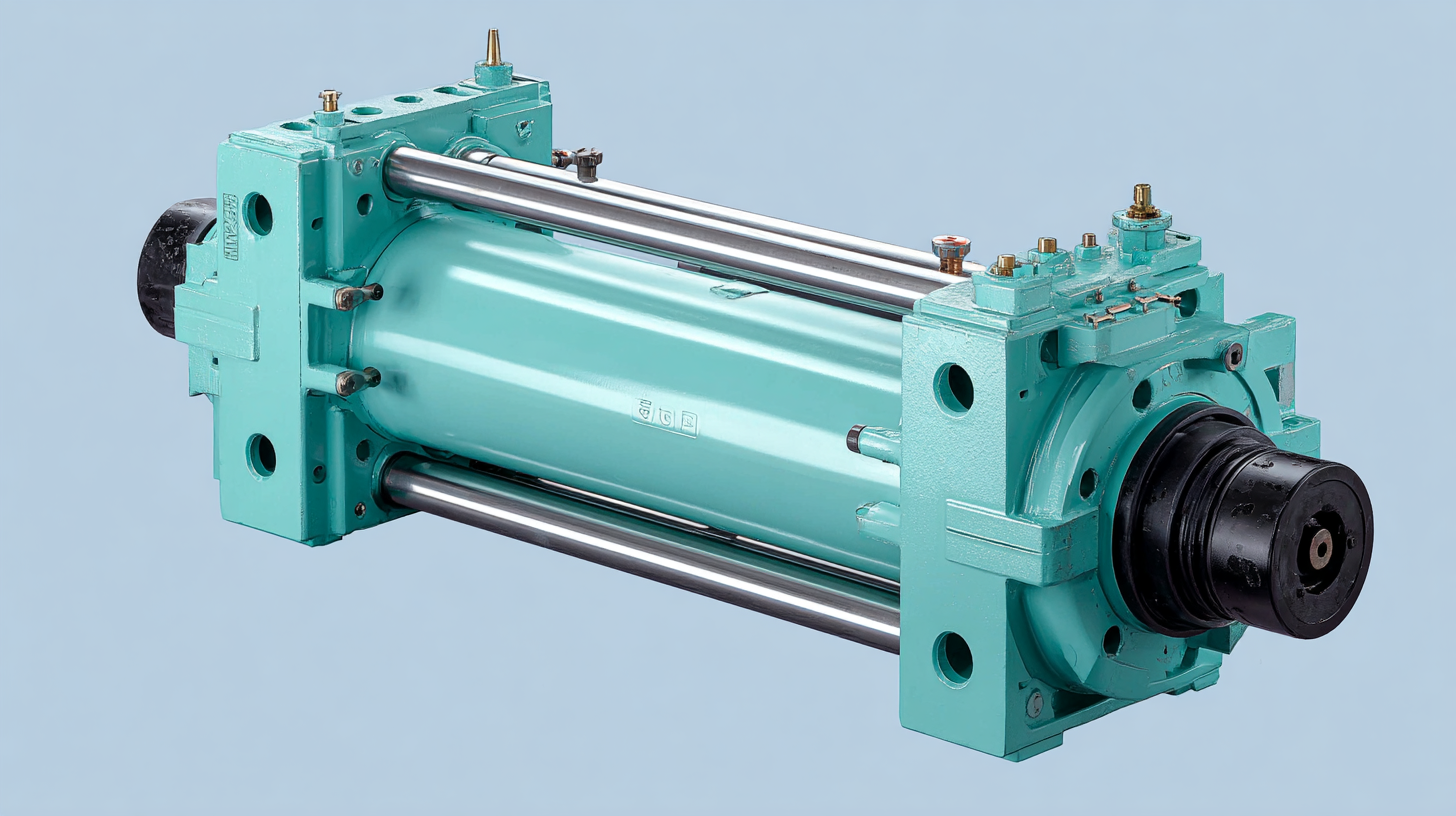

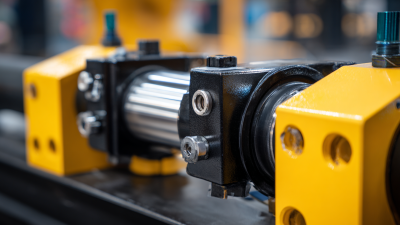

Understanding the Benefits of Replacement Hydraulic Cylinders for Enhanced Machinery Performance

In the world of industrial machinery, the performance and reliability of hydraulic systems are crucial for ensuring operational efficiency. Replacement hydraulic cylinders play a significant role in enhancing machinery performance, offering benefits such as improved reliability, reduced downtime, and cost savings. According to a recent report by the International Fluid Power Society, nearly 30% of hydraulic system failures are attributed to outdated or faulty cylinders, leading to substantial productivity losses. Upgrading to replacement hydraulic cylinders not only addresses these issues but also contributes to the longevity of equipment, as modern designs incorporate advanced materials and technologies that enhance performance. As the demand for efficient and dependable machinery continues to rise, investing in replacement hydraulic cylinders has emerged as a strategic solution for industries aiming to maintain a competitive edge in today's dynamic market.

How to Identify Signs That Your Hydraulic Cylinders Need Replacement

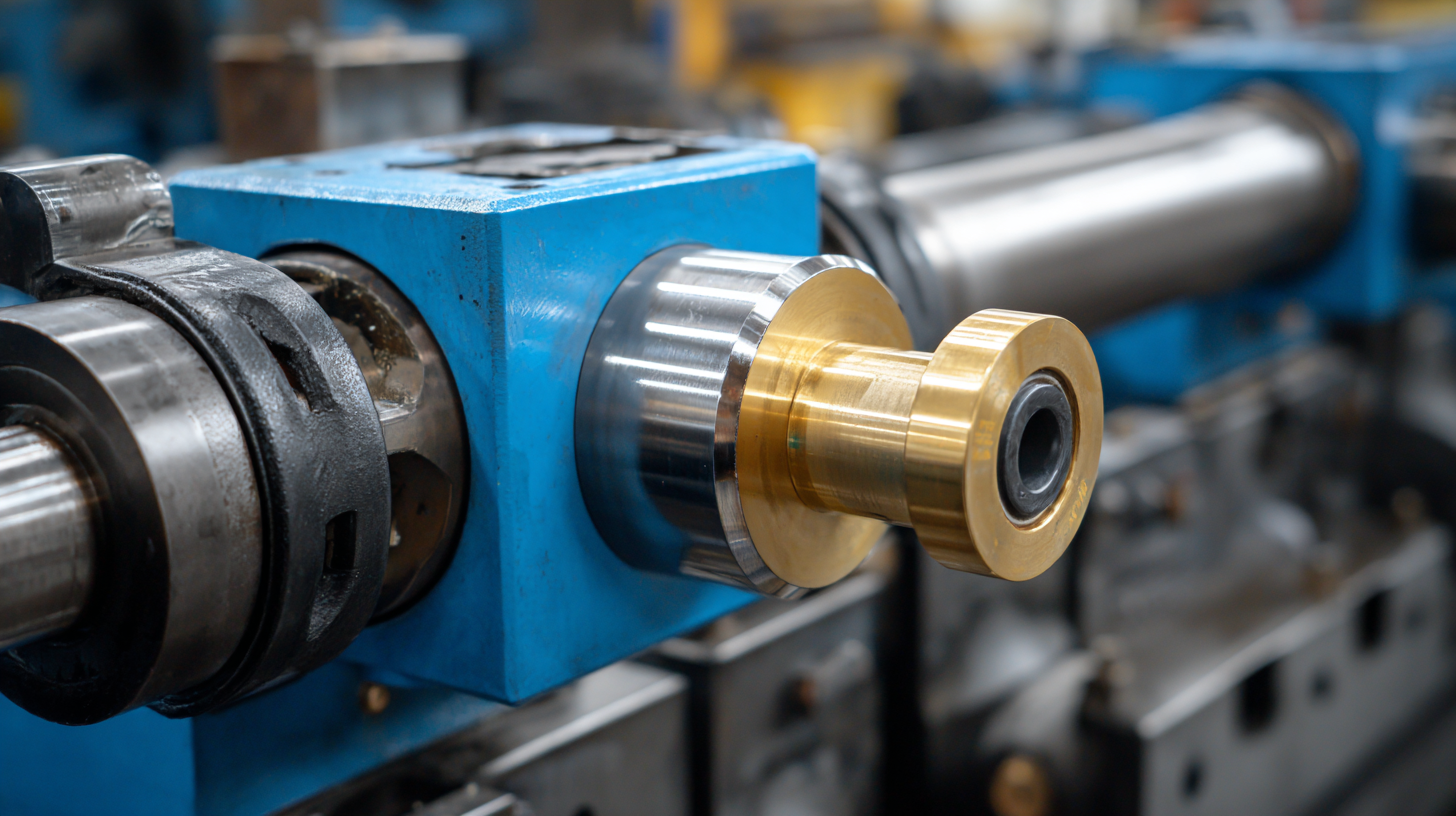

When it comes to maintaining heavy machinery, recognizing when hydraulic cylinders need replacement is crucial for optimal performance. One of the primary signs of failing hydraulic cylinders is noticeable fluid leaks. If you observe fluid pooling around or beneath the machinery, it’s a clear indication that seals may be compromised, allowing hydraulic fluid to escape. Additionally, you might notice a decrease in the efficiency or power output of your equipment; any erratic movements or sluggish responses can be a signal of hydraulic system failure.

**Tip:** Regularly inspect hydraulic hoses and connections for wear and tear. Addressing minor leaks promptly can prevent larger issues down the line.

Another critical sign to watch for is unusual noises coming from the hydraulic system, such as grinding or knocking sounds. These noises often indicate internal damage or the need for component replacement. Moreover, if the hydraulic cylinders are bulging or show signs of physical wear, it's time to consider a replacement. Proper maintenance involves staying vigilant about these signs and addressing them before they escalate into more significant, costly repairs.

**Tip:** Maintain a scheduled maintenance routine that includes checking for strange sounds and physical damage, ensuring your machinery operates smoothly and efficiently.

How to Choose the Right Replacement Hydraulic Cylinder for Your Machinery

When it comes to selecting the right replacement hydraulic cylinder for your machinery, understanding the specific needs of your application is crucial. Hydraulic cylinders play a pivotal role in the performance of various types of equipment, and choosing the correct one can significantly enhance efficiency and longevity. According to the Hydraulic Institute, improper cylinder selection can reduce machinery efficiency by as much as 30%, leading to increased operational costs and downtime.

To make an informed choice, consider factors such as the cylinder's stroke length, diameter, and pressure rating that align with your machinery's specifications. It's also essential to evaluate the environmental conditions, such as temperature and exposure to corrosive substances, which can impact the cylinder's performance. A report from TechSci Research indicates that the hydraulic cylinder market is expected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting the increasing importance of reliable and efficient hydraulic components in industrial applications. By focusing on these criteria, you can ensure optimal performance and minimize the risk of mechanical failure.

Understanding the Benefits of Replacement Hydraulic Cylinders

This chart illustrates the various benefits of replacing hydraulic cylinders in machinery, highlighting key areas such as increased efficiency and improved safety. The data reflects the percentage of users who reported these benefits after making replacements.

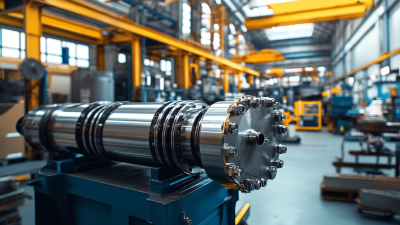

How to Install Replacement Hydraulic Cylinders Effectively and Safely

Installing replacement hydraulic cylinders is crucial for maintaining optimal machinery performance. To start, ensure you gather all necessary tools and equipment, including wrenches, hydraulic fluid, and safety gear. Before removal of the old cylinder, make sure to depressurize the hydraulic system to prevent any accidents. Disconnect all hoses, taking care to cap open ends to avoid contamination, and remove any mounting brackets.

Tips: Always consult the machinery’s manual for specific instructions regarding cylinder replacement. This will help you avoid any potential pitfalls and ensure compatibility with your equipment.

Once the old cylinder is removed, carefully position the new cylinder in place. Align it with the mounting points and securely fasten it using the appropriate hardware. Reconnect the hydraulic hoses, ensuring no leaks are present, and refill the hydraulic system with the correct type and amount of fluid. Finally, bleed the hydraulic system to remove any trapped air, and test the machinery to confirm that everything is working smoothly.

Tips: Take measurements and photographs during the disassembly process to assist in a smooth reinstallation. Keeping organized will save time and improve efficiency.

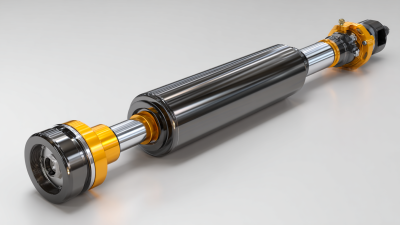

How to Maintain Your New Hydraulic Cylinders for Optimal Performance

Maintaining your new hydraulic cylinders is crucial for ensuring optimal performance and longevity. Regular maintenance can significantly reduce the frequency of costly repairs and downtime. According to a report by the Fluid Power Society, approximately 70% of hydraulic failures are attributed to poor maintenance practices. Therefore, adhering to a maintenance schedule can help prevent these issues and enhance the overall efficiency of machinery.

To maintain hydraulic cylinders effectively, it is essential to conduct regular inspections and monitor fluid levels. Contaminants such as dirt and water can severely damage seals and other internal components, leading to leaks and reduced performance. A study by the National Fluid Power Association showed that routine filtration and fluid replacement can prolong the lifespan of hydraulic systems by up to 40%. Additionally, ensuring that the cylinder rods are free of scratches and wear can prevent further deterioration of hydraulic performance over time. Implementing these practices not only maintains efficiency but also optimizes machinery performance, making it a worthwhile investment for any operation.

How to Evaluate the Cost-Benefit of Upgrading to Replacement Hydraulic Cylinders

When evaluating the cost-benefit of upgrading to replacement hydraulic cylinders, it is crucial to consider both direct and indirect impacts on machinery performance. First, analyzing the initial investment required for new hydraulic cylinders is essential. While premium replacement cylinders might come with a higher upfront cost, their potential to enhance efficiency and reduce downtime can lead to significant savings in the long run. A comparative analysis of operating costs should include factors such as energy consumption, maintenance frequency, and the expected lifespan of the new cylinders versus the existing ones.

Another important aspect to assess is the performance improvement that replacement hydraulic cylinders can offer. Enhanced machinery performance often results in increased productivity and operational reliability. Evaluating how these upgrades can minimize the risk of hydraulic failures and associated costs due to production halts is vital. Additionally, considering the technological advancements in replacement cylinders, such as improved materials and design, can provide insights into long-term benefits, enabling businesses to make informed decisions on their investment in machinery upgrades.

Understanding the Benefits of Replacement Hydraulic Cylinders for Enhanced Machinery Performance

| Evaluation Criteria | Old Hydraulic Cylinder | Replacement Hydraulic Cylinder | Cost-Benefit Ratio |

|---|---|---|---|

| Performance Efficiency | 75% | 90% | 1.2 |

| Maintenance Cost (Annual) | $1,500 | $800 | 1.9 |

| Lifespan (Years) | 5 | 10 | 2.0 |

| Downtime (Hours/Year) | 120 | 20 | 6.0 |

| Overall Efficiency Improvement (%) | - | 20% | - |

Related Posts

-

Innovative Strategies for Sourcing Hyd Cylinders Worldwide

-

Unlocking Global Supply Chain Efficiency with Our Unique Hydraulic Cylinder Catalogue Insights

-

Exploring the Characteristics and Applications of Best Replacement Hydraulic Cylinders for Global Buyers

-

2025 Insights: How Advanced Materials are Revolutionizing the Best Hydraulic Cylinder Industry

-

Exploring the Efficiency of Hyd Cylinders: Key Performance Metrics and Industry Insights

-

Resilient Growth of Chinese Manufacturers Amidst US China Tariff War with Focus on Best Compact Hydraulic Cylinder

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.