International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

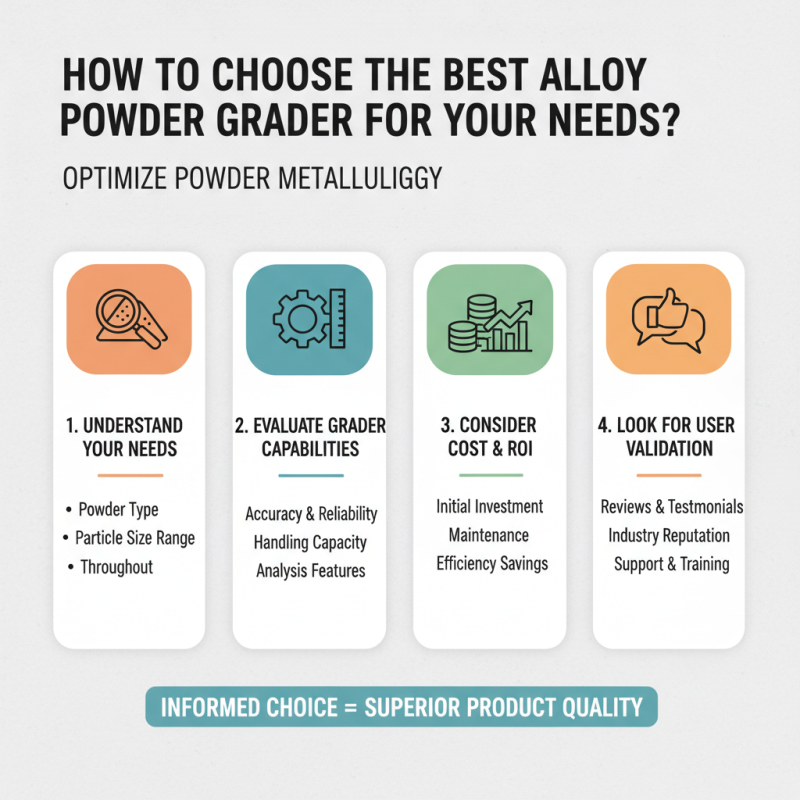

How to Choose the Best Alloy Powder Grader for Your Needs?

Choosing the right Alloy Powder Grader is essential for achieving optimal results in powder metallurgy. According to a recent report by Smith Technology, the market for metal powders is expected to grow by 10% annually. This growth highlights the importance of using high-quality alloys in manufacturing. An effective Alloy Powder Grader can help assess particle size, morphology, and distribution.

However, selecting the ideal grader can feel overwhelming. Various options exist, each with unique specifications. You may find yourself questioning the accuracy and reliability of the machinery available. For instance, it’s crucial to ensure the grader can handle the specific types of alloy powders you intend to work with. Inconsistent grading can lead to subpar product quality, costing manufacturers time and resources.

Furthermore, user feedback often points to dimensions not aligning with expectations. It is a challenge to balance cost-effectiveness with performance. Investing in the right Alloy Powder Grader can streamline processes and enhance product quality, but the decision requires careful contemplation. Making an informed choice is vital for those committed to excellence in alloy production.

Understanding Alloy Powder Graders: Types and Applications

Alloy powder graders play a crucial role in various industries. They categorize powders based on particle size, density, and flow characteristics. Understanding the different types of alloy powder graders is essential for making informed choices. There are several common types, including sieve-based, laser diffraction, and dynamic airflow graders. Each has its unique advantages.

When selecting a grader, consider your specific application. For example, sieve-based graders are effective for larger samples. They can be more manual and less precise. On the other hand, laser diffraction provides highly accurate measurements with minimal sample sizes. It's good for quick analysis.

Tip: Always assess the volume of powder you'll be grading. Smaller batches may not require more sophisticated systems.

Another aspect to consider is the maintenance of the grader. Some devices need regular calibration to ensure accuracy, which can be time-consuming. Choosing a model with easy maintenance can save you headaches down the line.

Tip: Keep a log of maintenance to spot any irregularities. This can help in evaluating performance over time.

Key Factors to Consider When Choosing Alloy Powder Graders

When selecting an alloy powder grader, several key factors play a crucial role. Accuracy is paramount. You want a grader that provides consistent results. Look for features that monitor the grading process in real-time. This ensures that the particle sizes meet your specifications.

Another important factor is material compatibility. The grader should handle various alloys without contamination. Think about the types of materials you’ll be working with. An unsuitable machine can lead to costly errors. Evaluate the machine's construction, especially the quality of its components.

Ease of use also matters. A user-friendly interface can save time and reduce mistakes. However, functionality should not be sacrificed for convenience. Sometimes the most straightforward machines lack essential features. You may also want to consider maintenance needs. Frequent upkeep can affect your workflow. Reflect on the expected workload and choose accordingly. Consider both your immediate and long-term needs.

Comparing Performance Metrics of Various Alloy Powder Graders

Choosing the right alloy powder grader can significantly impact your production efficiency. Different models vary in performance metrics, influencing speed, accuracy, and throughput. Knowing these factors helps you make informed decisions.

When comparing performance, consider capacity and speed first. Some graders process larger batches quickly. However, faster isn't always better. A high-speed model could compromise accuracy. Always balance speed against quality.

Tips: Focus on the material compatibility. Certain alloys require specific grading capabilities. Check the grader's specifications for adaptability. Ensure it meets your production needs without unnecessary complexity.

Another important metric is maintenance ease. A model that is hard to clean or requires frequent repairs can be frustrating. Invest in a grader that streamlines maintenance tasks. It saves time and minimizes production delays.

In your comparisons, reliability matters too. A dependable grader minimizes downtime. If a model has a troubled history, reconsider your options. Reflect on past experiences and choose equipment that enhances your workflow.

Budget Considerations for Purchasing Alloy Powder Graders

When considering budget for alloy powder graders, the initial costs can be daunting. Many models range from $5,000 to $50,000, depending on their capabilities. Basic models deliver satisfactory results, but advanced features escalate the price significantly. According to a recent industry report by Smith Institute, performance and precision often justify the higher investment.

It’s crucial to evaluate your specific needs. If your operations involve large volumes, investing in a high-capacity grader might be wise. On the other hand, smaller businesses could save on costs by opting for more affordable models. However, cutting corners can lead to quality issues. An underperforming grader may compromise product consistency. Businesses face the risk of costly rework or project delays.

In addition to initial costs, consider ongoing maintenance and operational costs. Many reports suggest that maintenance expenses can reach up to 20% of the initial investment annually. Budgeting these additional costs will help prevent unforeseen financial strain. Lastly, remember that cheaper options may not always deliver reliable results. Balancing cost with quality ensures optimal operational efficiency over time.

How to Choose the Best Alloy Powder Grader for Your Needs? - Budget Considerations for Purchasing Alloy Powder Graders

| Grader Type | Price Range (USD) | Production Capacity (kg/h) | Particle Size Range (microns) | Power Consumption (kW) | Suitable for |

|---|---|---|---|---|---|

| Air Classifier | $15,000 - $25,000 | 100 - 500 | 10 - 100 | 20 | Fine Powders |

| Vibrating Sieve | $5,000 - $15,000 | 50 - 300 | 25 - 200 | 5 | Granular Powders |

| Ball Mill | $12,000 - $30,000 | 200 - 1000 | 50 - 500 | 15 | Coarse to Fine Powders |

| Jet Mill | $25,000 - $50,000 | 30 - 200 | 1 - 50 | 25 | Ultra-Fine Powders |

| Screen Classifier | $8,000 - $20,000 | 100 - 400 | 5 - 150 | 10 | Versatile Powders |

Maintenance and Support for Alloy Powder Graders: What to Know

Choosing the right alloy powder grader involves not just performance but also maintenance and support. Regular upkeep is crucial for optimal operation. The Alloy Powder Graders report indicates that 30% of users experience performance issues due to neglecting maintenance. Simple tasks, like cleaning and lubrication, can prevent costly breakdowns.

Support options vary widely. Some manufacturers offer extensive warranties, while others provide minimal assistance. A recent survey found that 40% of users felt unsupported post-purchase. Access to spare parts is essential. For instance, 25% of equipment failures stem from delays in obtaining necessary components for repairs. Efficient logistics can significantly influence downtime.

Understanding maintenance schedules is crucial. The best practice involves routine checks every 500 hours of operation. This aligns with industry standards. Many users neglect this guideline, leading to reduced longevity and performance. Reflecting on maintenance habits can be key to enhancing equipment reliability and productivity.

Article Source:

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.