International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

How to Choose the Right Sandblast Rubber Hose for Your Needs?

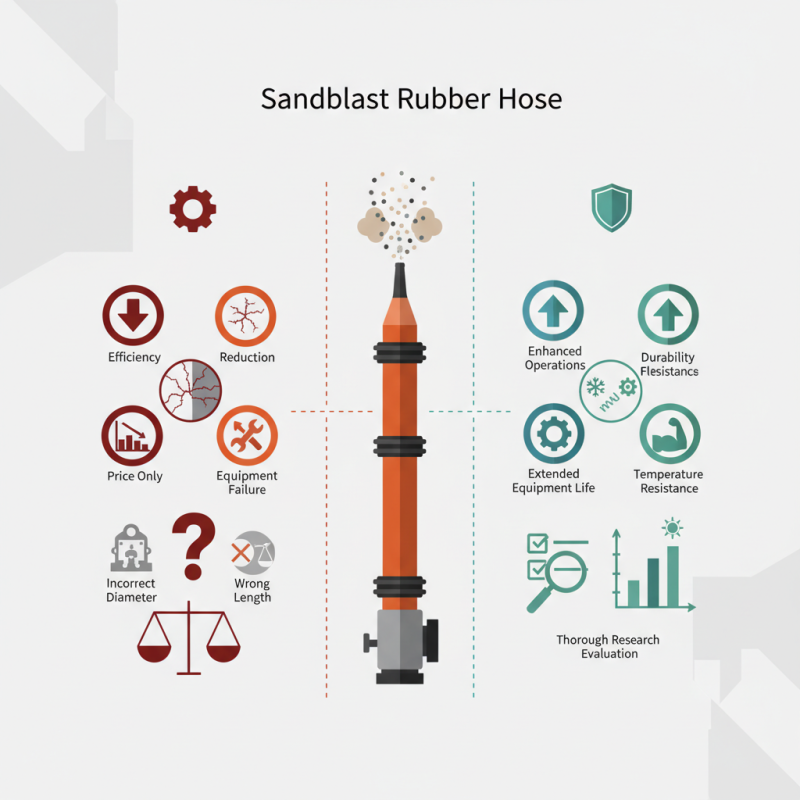

Choosing the right Sandblast rubber hose is crucial for effective performance in abrasive blasting applications. The industry standards reveal that improper selection can lead to up to 30% reduction in efficiency. Sandblast rubber hoses are specifically designed to withstand high pressures and abrasive materials. They play a vital role in various industries, including construction and manufacturing.

In recent studies, 70% of professionals reported issues due to using hoses that weren't suited for their specific tasks. Many overlooked the importance of diameter and length. Instead, they focused solely on price, risking equipment failure. It's essential to consider factors like flexibility, durability, and temperature resistance when selecting a hose. For instance, hoses that kink easily can cause disruptions and inefficiencies.

Reflecting on these challenges, it's clear that a deeper understanding of sandblast rubber hoses is vital. Conducting thorough research and evaluations will help avoid costly mistakes. The right choice can enhance your operations and extend equipment life. Let’s explore how to navigate this important decision-making process effectively.

Understanding the Basics of Sandblast Rubber Hoses

When choosing a sandblast rubber hose, understanding the basics is crucial. These hoses are designed to withstand abrasive materials. They come in various sizes, lengths, and thicknesses. The right choice depends on the specific tasks you'll perform.

Tips: Check the hose's inner diameter. A wider diameter can increase flow and efficiency. Consider the working pressure as well. You need a hose that matches your equipment's requirements. Durability matters too. Look for hoses that can handle wear and tear.

Sandblast hoses have multiple layers for strength. Some are reinforced with textiles or steel. This adds resilience but can increase weight. While a heavier hose might feel sturdy, it can become cumbersome. Think about how you'll handle it during your work.

Tips: Always evaluate the weight of the hose during use. If it feels unmanageable, your efficiency will drop. Regular maintenance is key. Check for signs of wear or damage to avoid future problems. Balancing durability and flexibility is essential for optimal performance.

Identifying Different Types of Sandblast Rubber Hoses

Choosing the right sandblast rubber hose starts with understanding the different types available. There are several options on the market. Each type serves a unique purpose.

Standard sandblast hoses are common. They are designed for general use in sandblasting applications. Then, you have heavy-duty hoses. These are thicker and more robust. They handle high pressure and abrasive materials better. However, selecting a heavy-duty hose can sometimes feel overwhelming.

Another option is a lightweight hose. This is easier to maneuver. It's perfect for smaller jobs or less demanding environments. But be cautious: lightweight hoses may not endure heavy use. Every choice has its pros and cons. Ensure you consider how often you'll use the hose. Match the hose type to your specific needs.

How to Choose the Right Sandblast Rubber Hose for Your Needs? - Identifying Different Types of Sandblast Rubber Hoses

| Type of Hose | Material | Diameter (inches) | Max Pressure (psi) | Applications |

|---|---|---|---|---|

| Standard Sandblast Hose | Rubber | 1.5 - 2.0 | 100 - 150 | General blasting, surface preparation |

| Heavy-Duty Sandblast Hose | Reinforced Rubber | 3.0 - 4.0 | 200 - 250 | Industrial blasting, abrasive materials |

| Lightweight Sandblast Hose | Polyurethane | 1.0 - 1.5 | 50 - 100 | Light-duty tasks, mobility-focused applications |

| Specialized Sandblast Hose | Chemical Resistant | 2.0 - 3.0 | 150 - 200 | Handling aggressive materials, chemical blasting |

Evaluating Hose Specifications and Compatibility

When selecting a sandblast rubber hose, understanding its specifications is crucial. Hoses vary in size, length, and material. Each attribute impacts performance significantly. For example, a hose that is too short may limit your reach. A hose that is too narrow can restrict airflow and reduce efficiency. Check the inner diameter for optimal airflow.

Compatibility matters as well. Ensure the hose connects seamlessly with your equipment. Investigate the hose’s fittings and connectors. Misalignment can lead to pressure drops. If the hose cannot withstand high pressure, it may burst. Pay attention to the hose's temperature resistance too. Sandblasting often generates heat. Choose a hose designed for high-temperature use to avoid failure.

Additionally, check the hose's flexibility. A stiff hose may not maneuver easily in tight spaces. Consider the environment where you'll use the hose. Exposure to chemicals or extreme temperatures could degrade materials over time. Reflect on your specific needs and adjust your choice accordingly. Testing different hoses in real applications can provide insights. Knowing the limits of each option helps avoid costly mistakes.

Comparative Analysis of Sandblast Rubber Hose Specifications

This chart displays a comparative analysis of the specifications for standard and premium sandblast rubber hoses, focusing on diameter, pressure rating, length, and weight. This information is essential for choosing the right hose for specific sandblasting needs.

Assessing Durability and Flexibility for Specific Applications

When selecting a sandblast rubber hose, durability and flexibility are key aspects to consider. A hose that is too rigid can be a challenge to maneuver, especially in tight spaces. You might find that some hoses easily kink under pressure, which can lead to inefficiencies. Flexibility allows for better handling, reducing strain during operation. Look for hoses that retain their shape without becoming unwieldy.

Durability is equally important. A hose exposed to abrasive materials must withstand the wear and tear of regular use. It’s essential to assess the material composition. Some hoses might claim to be durable but fail in real working conditions. Pay attention to user reviews or industry feedback. Unexpected failures in hoses can lead to costly downtime. It’s wise to choose a hose that strikes a balance between both attributes.

Consider your specific application. Different environments demand different levels of flexibility and durability. A hose that performs well in a controlled setting might not hold up in harsher conditions. Be mindful of the length as well; too long can hamper effectiveness. Each decision you make should align with your operational needs, ensuring you select the right hose for the task at hand.

Maintaining and Caring for Your Sandblast Rubber Hose

Proper maintenance of your sandblast rubber hose is crucial for its longevity and efficiency. Regular cleaning is essential to remove dust and debris that can accumulate inside the hose during use. Use a soft brush or cloth to gently clean the exterior, ensuring no particles are trapped. This simple act can prevent blockages and enhance performance.

Tips: Always inspect your hose for cracks or wear before each use. This can save you from unexpected breakdowns. If you notice any damage, consider replacing the hose immediately. Additionally, store your hose in a cool, dry place. Avoid direct sunlight, as excessive heat can deteriorate the rubber.

Caring for your sandblast rubber hose shouldn’t be overlooked. Ensure that you do not overstretch or kink the hose during operation. These actions can lead to weak points and ultimately result in leaks. After each use, hang the hose loosely to maintain its shape. Regularly check the fittings and connections for any signs of wear, as these can be just as vulnerable as the hose itself.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.