International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

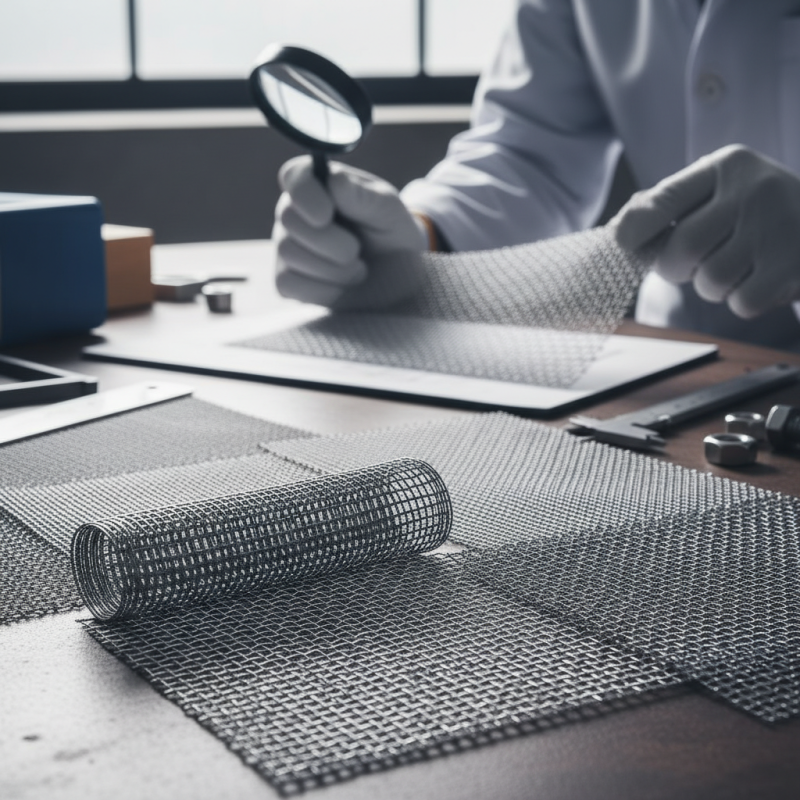

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

Choosing the right stainless steel wire mesh can be crucial for various applications. Expert John Smith, a renowned figure in the metal fabrication industry, states, “Selecting the appropriate mesh type can significantly impact your project’s success.” Each type of stainless steel wire mesh offers unique properties.

Different grades, opening sizes, and wire diameters can affect strength and corrosion resistance. It’s essential to consider your specific needs when making a selection. With the array of options available, the process may feel overwhelming. Many people struggle with the technical details of wire mesh specifications.

When choosing stainless steel wire mesh, it’s important to reflect on your intended use. For instance, industrial applications might demand higher durability compared to decorative purposes. Understanding your requirements will help narrow down your choices. Mistakes in selection can lead to costly failures or inadequate performance. Be sure to define your project clearly before making a decision.

Understanding the Different Types of Stainless Steel Wire Mesh Available

When selecting stainless steel wire mesh, understanding the types is crucial. Various types serve distinct purposes. The two common grades are 304 and 316 stainless steel. 304 is versatile and widely used. It offers good corrosion resistance, making it ideal for indoor applications. In contrast, 316 contains molybdenum, enhancing its resistance to saltwater and harsh environments. This makes it a better choice for marine and chemical applications.

Mesh configurations also vary significantly. Wire diameters can range from fine to coarse. For instance, a 0.5 mm diameter can filter out small particles, while a 2 mm offers larger openings. According to industry reports, the global stainless steel wire mesh market is expected to grow by 6.5% annually, driven by increased demand in construction and filtration. However, selecting the wrong type can lead to ineffective filtration or premature corrosion, necessitating careful evaluation of needs.

Visualizing your project can help clarify which mesh type fits best. Think about the environment and intended use. A fine mesh may look appealing and precise but can clog quickly in dirty settings. Alternatively, a coarser mesh allows more flow but may not catch finer particles. Balancing these factors requires thoughtful consideration. Don't rush; assess your specific needs carefully.

Key Factors to Consider When Selecting Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, consider your specific application. Different uses require varying specifications. Think about size, strength, and corrosion resistance. Each factor influences the performance of the mesh.

Tip: Determine the mesh size needed for your project. A tighter mesh blocks smaller particles but can affect airflow. Conversely, a larger mesh allows more flow but may not filter fine materials.

Material composition plays a key role too. Stainless steel type impacts durability. Some grades are better for high temperatures, while others excel in wet environments. Assess the environment where the mesh will be used, as this impacts longevity.

Tip: Test the mesh in your intended environment if possible. Real-world conditions can differ from theoretical expectations. What works on paper may fail in practice. Reevaluate your choices based on these observations. Choose wisely, as it could save time and costs down the line.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs? - Key Factors to Consider When Selecting Stainless Steel Wire Mesh

| Mesh Size (Inches) | Wire Diameter (Inches) | Opening Size (Inches) | Material Grade | Application |

|---|---|---|---|---|

| 1/4 | 0.025 | 0.125 | 304 | Filtration |

| 1/2 | 0.034 | 0.250 | 316 | Industrial Applications |

| 1 | 0.047 | 0.500 | 304 | Construction |

| 2 | 0.065 | 0.750 | 430 | High-Temperature Use |

| 3/8 | 0.030 | 0.187 | 304 | Food Processing |

Evaluating Wire Diameter and Wire Gauge for Optimal Performance

Choosing the right stainless steel wire mesh requires careful consideration, especially of wire diameter and wire gauge. These two factors significantly affect performance and durability. Wire gauge is a standard measure, often indicating the thickness of the wire. Lower gauge numbers mean thicker wire, while higher numbers indicate thinner wire. Reports suggest that a wire diameter between 0.5 mm to 2 mm often suffices for industrial applications, balancing strength and flexibility.

Moreover, the choice of wire diameter enhances the mesh's functionality in various environments. For example, a diameter of 1 mm suits applications needing durability but may compromise filtration efficiency. A study conducted by the International Stainless Steel Forum indicates that using a 0.7 mm wire provides optimal performance in water filtration systems. However, sometimes, thicker wires may block finer particles more effectively. This trade-off should not be overlooked.

It's vital to remember that wire specifications can vary significantly depending on the intended application. Many industries report issues when choosing wire mesh solely based on strength. In certain cases, a wire gauge that is too thick may lead to reduced airflow and hinder operational effectiveness. Refining this process requires real-world testing and application-based feedback. This approach ensures that the selected mesh meets not only durability standards but also performance needs in specific settings.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

Assessing Wire Mesh Open Area and Its Impact on Efficiency

Choosing the right stainless steel wire mesh requires careful consideration of open area, which significantly impacts efficiency. Open area is defined as the percentage of mesh that is free of material. A higher open area generally allows for better airflow and fluid movement. Studies show that optimal open area can improve efficiency by up to 30%. This statistic highlights the crucial nature of selecting the correct mesh size for your application.

For example, in filtration applications, a mesh with 60% open area might be ideal for capturing larger particles, whereas a mesh with 80% open area is better for finer particles. However, achieving a balance can be tricky. A mesh that’s too open might let unwanted materials pass through. Conversely, a mesh that’s too dense could clog quickly and reduce overall throughput. Many users report that they initially overlook these details, which leads to subpar performance. Understanding the right balance is essential to avoid costly mistakes.

Not every application requires the same specifications. Assessing air flow rate, fluid viscosity, and pressure are critical as well. Some industries may prioritize durability over open area, which complicates the decision-making process. Manufacturers often face imperfect choices; selecting wire mesh remains a challenge that demands attention to these finer details.

Choosing the Right Stainless Steel Alloy for Specific Applications

When selecting the right stainless steel alloy, understanding the specific application is crucial. Different alloys offer varying levels of corrosion resistance, strength, and temperature tolerance. For example, Type 316 is known for its excellent resistance to corrosion in marine environments, while Type 304 is suitable for food processing. Industry reports indicate that approximately 75% of stainless steel produced is of Type 304 and Type 316 due to their versatility.

Tip: Assess the environment where the mesh will be used. Will it be exposed to harsh chemicals or extreme temperatures? This can guide your choice of alloy.

Besides corrosion resistance, consider the mechanical properties required. If high tensile strength is necessary, alloys like 17-4 PH might be the best choice. In a recent study, it was found that this alloy can sustain stress at temperatures exceeding 600°F. However, it may not be ideal for all applications due to challenges in formability.

Tip: Always test samples in your actual use case. This can reveal potential weaknesses.

Analyzing cost-effectiveness is another factor. The initial investment in higher-grade alloys may seem significant, but their durability can lead to longer life cycles and lower maintenance costs. Not all stainless steel wire meshes are created equal, and selecting a lower-grade option might lead to unforeseen failures.

Article Source:

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.