International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

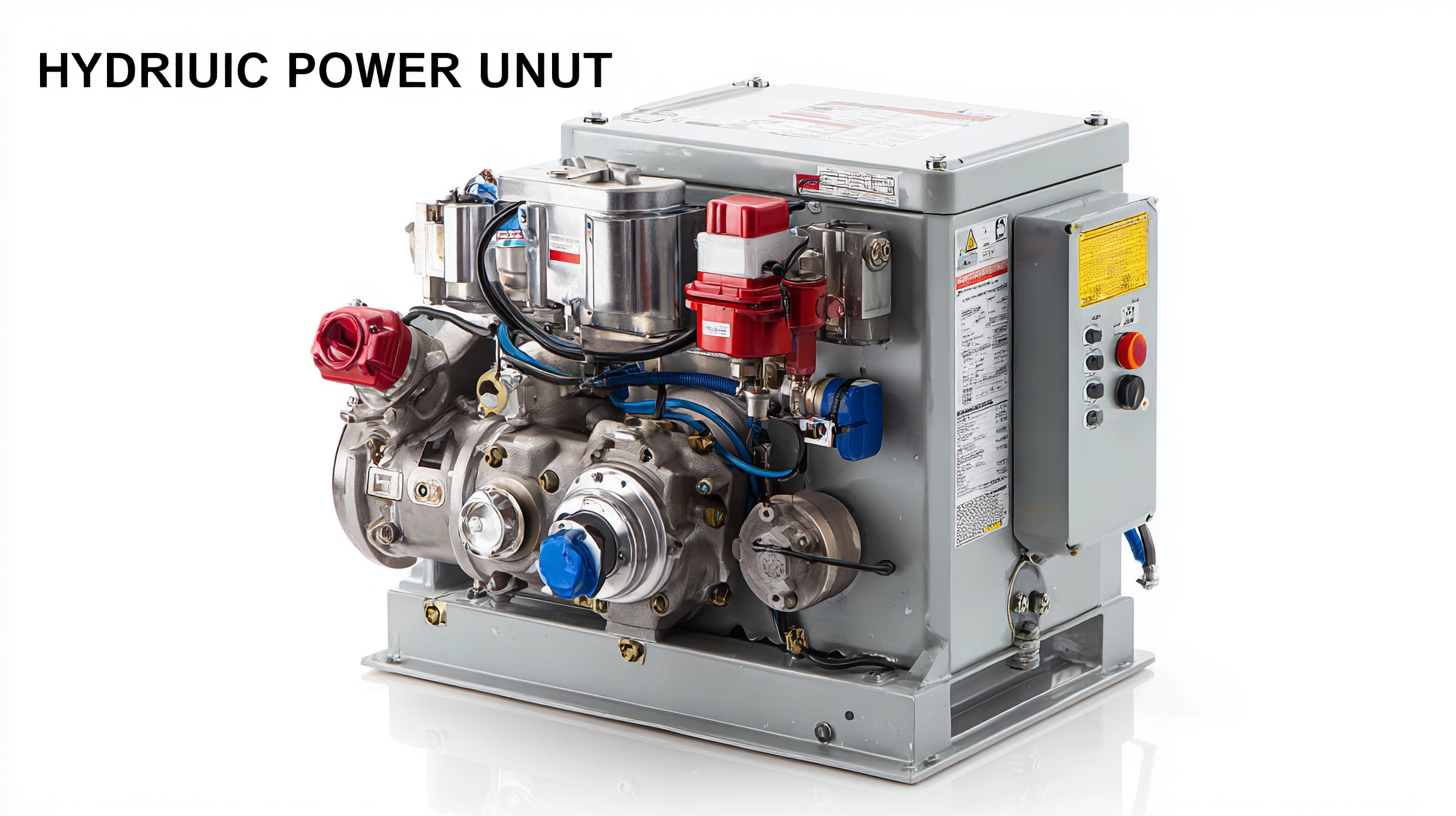

Choosing the Right Manufacturer for Best Hydraulic Power Units A Comprehensive Comparison Guide

In the rapidly evolving world of industrial machinery, selecting the right manufacturer for Hydraulic Power Units (HPUs) is crucial for maximizing efficiency and performance. According to a recent industry report by MarketsandMarkets, the global hydraulic equipment market is projected to reach $48.7 billion by 2026, driven by the increasing demand for automation and precision in construction and manufacturing sectors. As organizations strive to enhance productivity, understanding the unique characteristics and suitable applications of different types of hydraulic power units becomes essential. This guide aims to provide a comprehensive comparison of various HPU types, empowering businesses to make informed decisions when investing in this critical component. By examining factors such as power density, operational efficiency, and compatibility with existing systems, this resource will assist you in identifying the best hydraulic power unit for your specific needs and applications.

Key Trends in Hydraulic Power Unit Manufacturing for 2025

As we look toward 2025, the hydraulic power unit manufacturing industry is expected to experience notable transformations driven by technological advancements and sustainability goals. One major trend is the increased integration of automation and IoT technology. Manufacturers are embracing smart hydraulic power units that offer real-time monitoring and predictive maintenance, significantly improving operational efficiency and reducing downtime.

Tip: When selecting a manufacturer, ask about their commitment to innovative technologies and how they can enhance the performance of your hydraulic systems. Evaluating their capabilities in automation can be a game-changer for your operations.

Another key trend is the growing focus on eco-friendly practices. Manufacturers are now prioritizing the development of hydraulic power units that minimize energy consumption and utilize biodegradable fluids. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers.

Tip: Inquire if the manufacturer employs sustainable materials in their products and how they address environmental impact throughout their supply chain. Selecting a manufacturer aligned with eco-friendly values can support your company’s sustainability goals.

Choosing the Right Manufacturer for Best Hydraulic Power Units A Comprehensive Comparison Guide - Key Trends in Hydraulic Power Unit Manufacturing for 2025

| Dimension | Value | Trends |

|---|---|---|

| Average Power Output | 50-200 HP | Increasing demand for efficiency |

| Standard Pressure Range | 1500-5000 PSI | Shift towards higher pressures |

| Hydraulic Fluid Type | Biodegradable options available | Focus on sustainability |

| Control System Type | Electronic vs. Manual | Growth in automation |

| Typical Applications | Construction, Manufacturing | Diversifying into new sectors |

| Expected Market Growth Rate | 5% CAGR | Rising investment in infrastructure |

Essential Features to Consider When Choosing a Hydraulic Power Unit

When selecting a hydraulic power unit (HPU), several essential features must be considered to ensure optimal performance and reliability. One critical factor is the power output of the unit, typically measured in horsepower (HP) or kilowatts (kW). According to the International Fluid Power Society, choosing the appropriate power rating can significantly affect the efficiency and operational lifespan of hydraulic systems. HPUs with a power output that closely matches the required specifications of the application can lead to improved energy efficiency, potentially reducing operational costs by up to 20%.

Another crucial feature is the design and construction materials of the hydraulic power unit. High-quality HPUs often utilize durable materials such as aluminum or stainless steel to withstand harsh operating environments. A study by the Fluid Power Journal highlights that units made with superior materials have a failure rate 30% lower than their counterparts. Additionally, consider the system's filtration capabilities; efficient filtration can extend the life of the hydraulic fluid and reduce maintenance costs, as noted by the National Fluid Power Association. By focusing on these essential features, users can make informed decisions, ultimately enhancing their operational efficiency and system reliability.

Evaluating Manufacturer Reputation: What to Look For

When evaluating manufacturers for hydraulic power units, reputation is paramount. A company’s reputation can often indicate its reliability, quality of products, and customer service. Potential buyers should consider industry certifications, reviews from past customers, and recommendations from peers. For instance, organizations should assess whether a manufacturer has a history of long-standing operations and positive client relationships, which are strong indicators of trustworthiness.

Moreover, due diligence in checking a manufacturer's reputation can save time and mitigate risks. It's essential to look into their management practices, as effective management usually correlates with good operational outcomes and a solid reputation. Different metrics, including a company’s commitment to environmental, social, and governance (ESG) criteria, can also provide insights into its ethical standards and long-term sustainability. Ultimately, a strong reputation is not just beneficial for manufacturers; it directly impacts customers' confidence and decision-making when selecting a supplier for hydraulic power units.

Cost vs. Quality: Finding the Right Balance in Hydraulic Units

When selecting a hydraulic power unit, one of the most critical decisions revolves around balancing cost and quality. Lower-priced units may initially appear attractive, but they often compromise on materials and performance, leading to frequent maintenance and replacement costs. On the other hand, higher-quality units designed with robust materials and advanced technology tend to offer greater durability and efficiency, ultimately resulting in savings over time. Therefore, it is essential for buyers to assess their specific needs and operational demands carefully.

Investing in a reliable hydraulic power unit means considering the long-term implications of the purchase. While a cheaper option might fit within a tight budget, the reduced lifespan and potential for performance issues can lead to greater expenses down the line. Industry professionals recommend prioritizing quality, especially for critical applications where downtime can significantly impact productivity. Balancing cost with quality requires thorough research and possibly seeking guidance from manufacturers who prioritize high standards without unnecessary markups.

Sustainability in Manufacturing: The Future of Hydraulic Power Solutions

As the industrial landscape evolves, sustainability has emerged as a pivotal aspect of manufacturing, especially in the production of hydraulic power units. According to a recent report by the Global Alliance for Action on Climate Change, manufacturers are now prioritizing eco-friendly practices, leading to a 25% reduction in carbon emissions within the hydraulic sector over the past five years. This shift not only helps mitigate environmental impact but also introduces innovative technologies that enhance energy efficiency, such as variable speed drive systems and advanced fluid management practices that optimize hydraulic operation.

Moreover, the demand for sustainable hydraulic solutions is increasingly reflected in consumer preferences. A survey conducted by the International Hydraulic Industry Association found that 78% of respondents are more inclined to partner with manufacturers that demonstrate a commitment to sustainability. This growing awareness has prompted manufacturers to invest in renewable materials and environmentally friendly manufacturing processes, yielding products that not only perform efficiently but also adhere to global sustainability goals. As we move forward, the focus on sustainability in hydraulic power solutions is likely to shape the industry, driving both innovation and responsibility towards a greener future.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.