International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

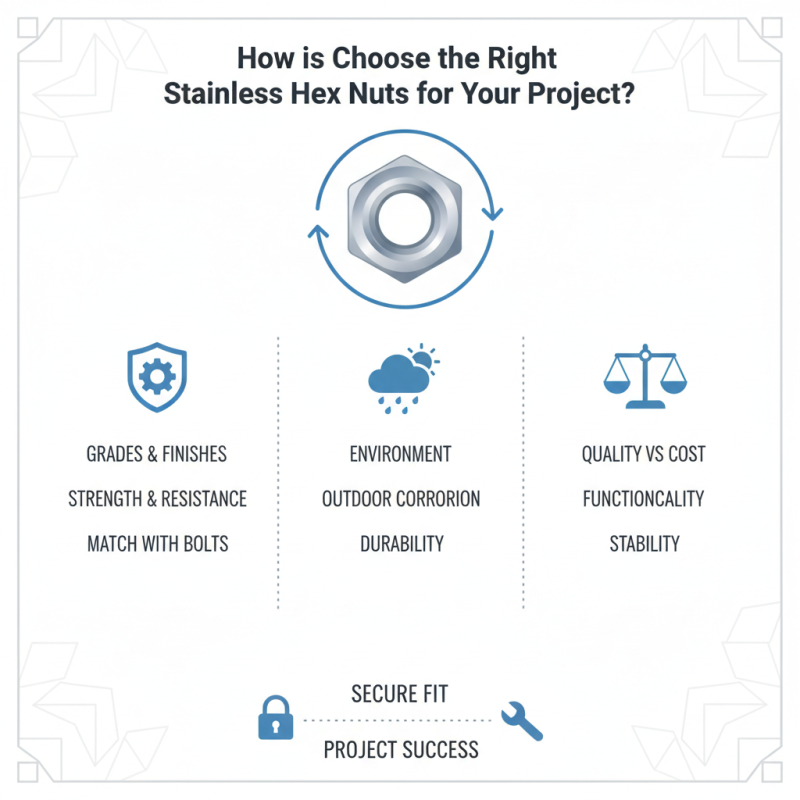

How to Choose the Right Stainless Hex Nuts for Your Project?

Choosing the right Stainless Hex Nuts can make or break your project. These small yet crucial items are often overlooked. However, they play a significant role in ensuring the stability and durability of your assembly.

Stainless hex nuts are available in various grades and finishes. Each option offers different strengths and resistances. Understanding these differences is key. Improper selections can lead to rust or failure under pressure. It's essential to match the correct nuts with your bolts for a secure fit.

Consider the environment where your project will exist. Outdoor settings require higher resistance to corrosion. Look for nuts that are not just stylish but also functional. Reflect on the balance between quality and cost. Find the perfect mix to achieve success in your venture.

Understanding the Different Grades of Stainless Hex Nuts

When choosing stainless hex nuts, understanding the different grades is essential. Stainless steel nuts generally fall into several grades. The most common are 304 and 316 grades. Grade 304 is excellent for everyday use. It provides good corrosion resistance and is suitable for indoor projects. However, it might not hold up well in environments with high moisture or salt exposure.

Grade 316 offers improved corrosion resistance. This grade contains molybdenum, which makes it a better option in marine and chemical environments. According to industry reports, 316 stainless steel nuts can withstand harsher conditions. They are a preferred choice for outdoor applications. Despite its advantages, 316 nuts can be more expensive. Thus, project budgets should be carefully considered.

Selecting the right grade is important but not always straightforward. Even skilled professionals sometimes overlook these details. Poorly chosen nuts can lead to rust or structural failures. Research shows that about 40% of projects face delays due to improper fastener selection. Therefore, understanding the specific requirements of your project is vital. Exploring your options ensures longevity and performance in the long run.

How to Choose the Right Stainless Hex Nuts for Your Project? - Understanding the Different Grades of Stainless Hex Nuts

| Grade | Material Composition | Corrosion Resistance | Common Applications | Tensile Strength (ksi) |

|---|---|---|---|---|

| A2 (304) | 18% Cr, 8% Ni | Moderate | General construction, food processing | 85 |

| A4 (316) | 16% Cr, 10% Ni, 2% Mo | High | Marine environments, chemical processing | 80 |

| A5 (410) | 11.5% Cr | Moderate | Cutlery, architectural applications | 95 |

| B8 (304) | 18% Cr, 8% Ni, Steel | Moderate | High-temperature applications | 75 |

| B8M (316) | 16% Cr, 10% Ni, 2% Mo | Very High | Pharmaceuticals, food processing | 70 |

Factors to Consider When Selecting Stainless Hex Nuts

Choosing the right stainless hex nuts involves considering several factors. First, the material grade is crucial. Common options include 304 and 316 stainless steel. The former is suitable for general applications, while the latter offers enhanced corrosion resistance. This becomes vital in harsh environments, like coastal areas.

Another key factor is the size and thread type. Ensure the hex nuts fit the bolts you plan to use. Mismatched sizes can lead to project failures. Thread pitch is also important; finer threads provide more grip but may be less durable under certain conditions.

Consider the intended application as well. If your project involves high loads, select nuts with higher strength ratings. Think about how often you’ll need to remove and replace the nuts. Some designs are more convenient than others. However, not all nuts are easy to work with. You might find that some strip during installation or require special tools. Reflecting on these aspects will help you make a well-informed choice.

Comparing Finishes and Coatings for Stainless Hex Nuts

When selecting stainless hex nuts, finishes and coatings are crucial. The right finish can enhance performance and longevity. Stainless steel is naturally resistant to corrosion, but specific coatings can offer additional protection. For example, a galvanized finish adds a layer, making it suitable for outdoor projects.

Some coatings may seem more appealing but come with trade-offs. A bright finish may look good initially, but it can wear off quicker under stress. Meanwhile, a dull finish might blend better in certain applications, yet it might not provide the same corrosion resistance. Choosing between aesthetics and function requires careful thought.

Surface factors like texture and color also play a role. A rough surface may secure grip but can be more difficult to clean. In contrast, a smoother finish is easier to maintain but may slip more easily under load. Reflecting on these aspects can guide you toward a more informed choice.

Determining the Right Size and Thread Pitch for Your Needs

When choosing hex nuts, understanding size and thread pitch is crucial. The wrong size can lead to stripping or loosening. Industry reports indicate that approximately 30% of hardware failures arise from incorrect nut sizing. Measure accurately with calipers to ensure you select a nut that fits snugly. The size should correlate with the bolt diameter for optimal performance.

Thread pitch is another critical consideration. It refers to the distance between threads. Standard pitches exist, but custom pitches can be necessary for specific applications. Research indicates that 40% of mechanical failures stem from mismatched thread pitches. Always refer to standardized charts for thread characteristics. Assessing both width and pitch can significantly reduce the risk of future issues.

It's easy to overlook these details, yet they can impact your project profoundly. A missing measurement can lead to assembly delays. Sometimes, it's worth testing different sizes or pitches. This experimentation can yield valuable insights and improve overall project outcomes. Taking the time to validate your choices prevents costly mistakes in the long run.

Assessing Environmental Conditions for Optimal Hex Nut Performance

When selecting stainless steel hex nuts, understanding environmental conditions is critical. Factors such as humidity, temperature, and chemical exposure can significantly affect performance. For instance, in coastal areas, saltwater corrosion can become an issue. It's essential to consider the specific environment in which the nuts will be used to ensure durability.

**Tip:** Assess the location before making a purchase. If it's a marine environment, opt for options that have higher corrosion resistance.

Temperature fluctuations can also impact the integrity of hex nuts. High heat can cause nuts to expand, while cold may lead to contraction. This can affect the tightness of the connection. Be aware of the material's thermal properties.

**Tip:** Conduct tests if possible. Sometimes, assumed conditions differ greatly from reality. Mistakes in this area could lead to project failure.

Chemical exposure also plays a crucial role. Certain acids or bases can degrade some types of stainless steel. Identify the chemicals present and their concentration levels. Ignoring this can lead to potentially expensive repairs down the line.

**Tip:** Consult with professionals if unsure. Their insights can clarify which materials are suitable, reducing the risk of unforeseen issues.

Article Source:

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.