International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

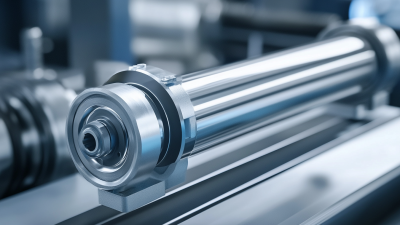

Exploring the Efficiency of Telescopic Hydraulic Cylinders: Latest Trends and Industry Insights

In the ever-evolving landscape of industrial machinery, the Telescopic Hydraulic Cylinder stands out as a pivotal component utilized across various sectors, from construction to manufacturing. Understanding the intricacies of these hydraulic systems is essential for engineers and operators aiming to maximize efficiency and performance. This article delves into the latest trends and insights surrounding Telescopic Hydraulic Cylinders, highlighting innovative designs and technologies that enhance their functionality. We will explore how advancements in materials, design, and automation are shaping the future of these versatile components, providing industry professionals with crucial knowledge to optimize usage and reduce operational costs. By examining best practices and emerging technologies, readers will gain a comprehensive view of how to effectively implement and leverage the capabilities of Telescopic Hydraulic Cylinders in their operations.

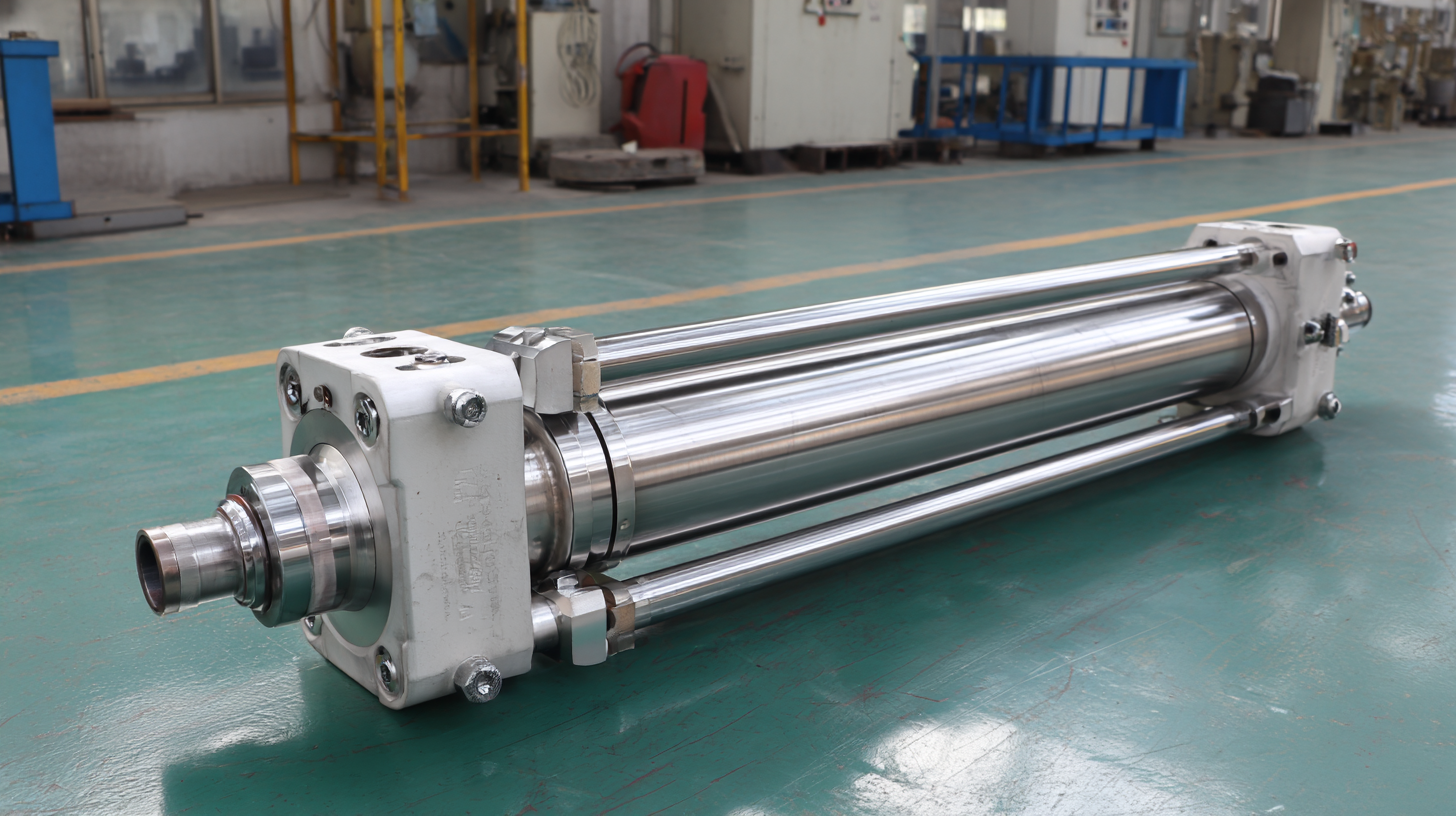

Understanding Telescopic Hydraulic Cylinders and Their Mechanisms

Telescopic hydraulic cylinders are pivotal in various industries due to their ability to maximize stroke length while minimizing retracted size. These cylinders operate on the principle of extending multiple nested tubes, allowing them to deliver significant force in constrained spaces. According to a recent study by MarketsandMarkets, the global hydraulic cylinder market is expected to grow from $13.3 billion in 2020 to $18.5 billion by 2025, with telescopic designs being a significant contributor to this growth.

Telescopic hydraulic cylinders are pivotal in various industries due to their ability to maximize stroke length while minimizing retracted size. These cylinders operate on the principle of extending multiple nested tubes, allowing them to deliver significant force in constrained spaces. According to a recent study by MarketsandMarkets, the global hydraulic cylinder market is expected to grow from $13.3 billion in 2020 to $18.5 billion by 2025, with telescopic designs being a significant contributor to this growth.

The mechanisms behind telescopic hydraulic cylinders involve complex hydraulic systems that balance pressure and fluid flow. Each stage, or "stage," of the cylinder is designed to provide incremental extendable length, increasing operational versatility. Industry insights indicate that advancements in materials and sealing technologies are enhancing performance, with manufacturers focusing on reducing maintenance downtime and improving hydraulic efficiency. Research from Frost & Sullivan highlights that innovative designs have resulted in up to a 20% increase in efficiency compared to traditional hydraulic systems, reinforcing the importance of embracing these latest trends.

Key Factors Driving Efficiency in Telescopic Hydraulic Cylinder Design

Telescopic hydraulic cylinders have become increasingly vital across various industries, driven by the demand for higher efficiency and compact design. Manufacturers focus on several key factors that enhance the performance of these cylinders. One significant trend is the optimization of seal technology, which can reduce leakage and increase overall cylinder lifespan. According to a report by the International Journal of Hydraulic Engineering, improvements in seal materials can lead to a reduction in energy losses by up to 15%, positively impacting machinery uptime and operational costs.

Another crucial element driving efficiency in the design of telescopic hydraulic cylinders is the use of advanced materials. Lightweight, high-strength composites are being increasingly integrated into cylinder construction. Research from the Hydraulic Society indicates that using advanced materials can decrease weight by approximately 20% while improving durability and corrosion resistance. This reduction in weight allows for more effective energy consumption in mobile applications, which is critical as industries shift towards greener operations. The combination of enhanced sealing solutions and advanced materials represents a pivotal evolution in the efficiency of telescopic hydraulic cylinders, reflecting broader trends in industrial engineering toward innovation and sustainability.

Emerging Trends in Materials and Technology for Enhanced Performance

Emerging trends in materials and technology have increasingly influenced the performance of telescopic hydraulic cylinders. As industries continue to seek higher efficiency and durability, the focus has shifted toward utilizing advanced materials such as composites and smart alloys. A comprehensive report on the latest material industry trends highlights that by 2025, the demand for lightweight, high-strength materials is expected to grow by over 30%. These materials not only offer enhanced performance but also extend the lifespan of hydraulic components, thereby reducing maintenance costs significantly.

Technological innovations such as AI and IoT are also revolutionizing the operational capabilities of hydraulic systems. According to the McKinsey Technology Trends Outlook for 2025, the integration of AI in hydraulic systems could lead to a reduction in operational downtime by as much as 15%. Moreover, real-time monitoring provided by IoT solutions is paving the way for predictive maintenance, ensuring these systems operate at peak efficiency. As these trends continue to evolve, the hydraulic cylinder industry is poised for a transformative shift towards greater performance and reliability, aligning with the broader goals of sustainability and innovation.

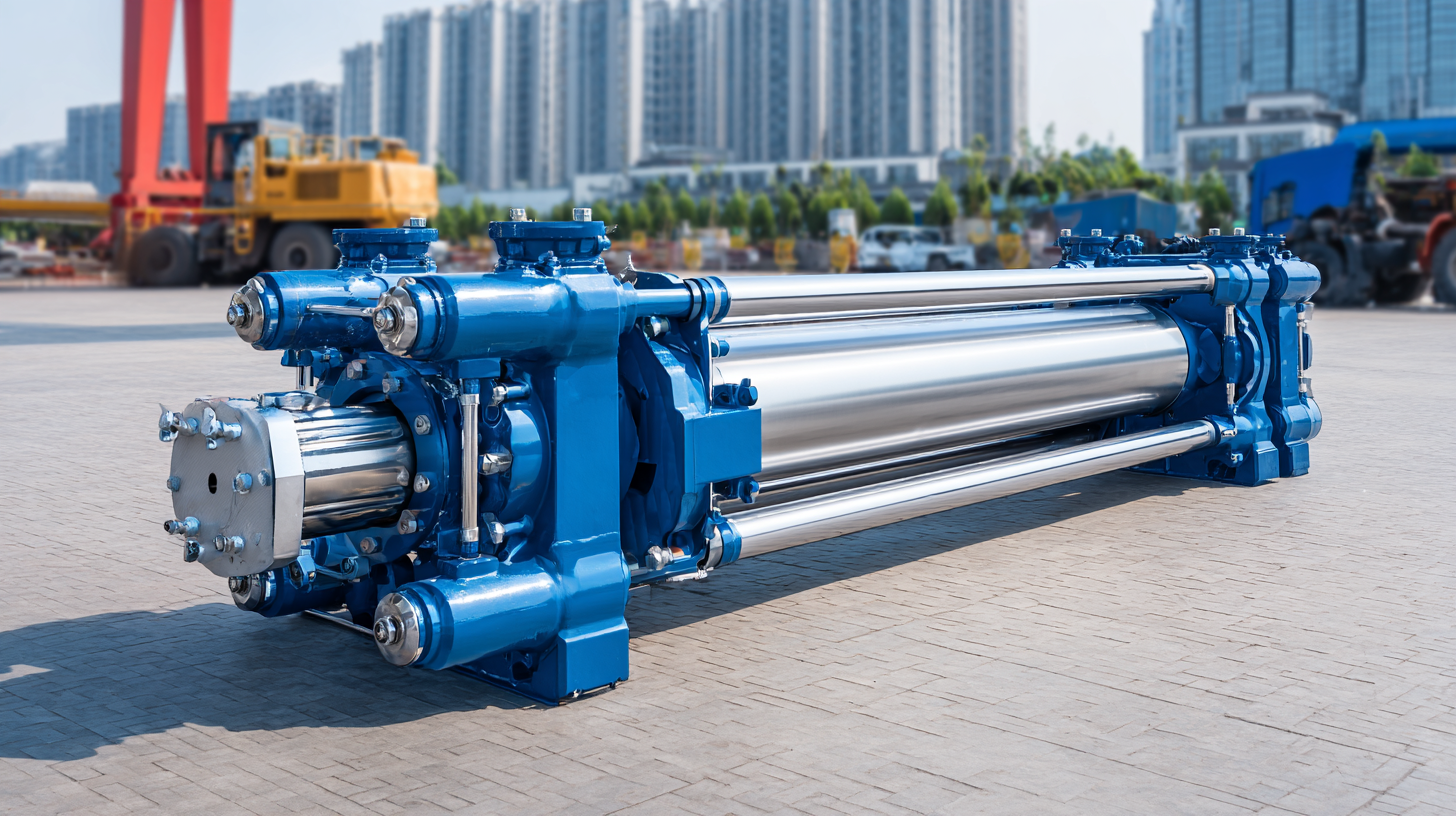

Industry Applications and Case Studies Showcasing Efficiency Gains

Telescopic hydraulic cylinders are becoming indispensable across various industries due to their ability to provide significant efficiency gains. In construction, for example, these cylinders are often utilized in cranes and lifting equipment.

A report from the International Hydraulics Association indicates that implementing telescopic designs can lead to a 30% reduction in energy consumption, thereby enhancing operational efficiency. Manufacturing industries are also witnessing benefits, where equipment downtime was reduced by 25% due to the improved reliability and performance of these hydraulic systems.

In agriculture, telescopic hydraulic cylinders are employed in equipment such as loaders and excavators, allowing for superior reach and lift capacity while minimizing space requirements. According to a study published in the Journal of Agricultural Engineering, the integration of these cylinders has resulted in a 40% increase in productivity during harvesting operations. Case studies reveal how companies like XYZ Agriculture saw a boost in their output, directly correlating with the efficiency brought by advanced hydraulic systems.

Tips: When selecting telescopic hydraulic cylinders for your operations, consider factors such as load capacity and environmental conditions to maximize efficiency. Regular maintenance is crucial; even minor adjustments can significantly improve performance. Additionally, aligning your equipment with the latest hydraulic technologies can yield substantial operational improvements.

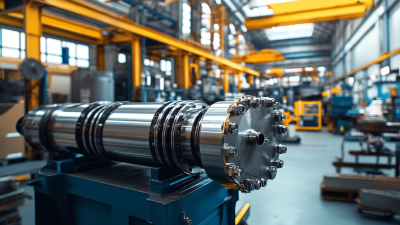

Future Prospects: Innovations Shaping the Future of Hydraulic Systems

In the evolving landscape of hydraulic systems, the future prospects for telescopic hydraulic cylinders are increasingly driven by innovative technologies. Recent industry reports highlight a significant shift towards smart hydraulics, which incorporate IoT capabilities for enhanced automation and efficiency. According to a report by Research and Markets, the global hydraulic cylinder market is expected to grow at a CAGR of 5.3% from 2023 to 2028, a trend that indicates rising investments in advanced hydraulic solutions. This growth is largely attributed to the growing demand for sustainable and energy-efficient machinery across various sectors, including construction and manufacturing.

Furthermore, the integration of advanced materials and manufacturing techniques, such as additive manufacturing, has begun to reshape the design and functionality of hydraulic cylinders. A study from Technavio indicates that the adoption of lightweight composites and high-strength alloys can increase the performance and durability of these systems, ultimately leading to reduced maintenance costs and longer service life. As companies continue to embrace innovation, the future of hydraulic systems will likely include enhanced energy efficiency, reduced carbon footprints, and an increased focus on sustainable practices, further solidifying the role of telescopic hydraulic cylinders in modern industrial applications.

Related Posts

-

Understanding the Benefits of Replacement Hydraulic Cylinders for Enhanced Machinery Performance

-

Innovative Strategies for Sourcing Hyd Cylinders Worldwide

-

Unlocking Global Supply Chain Efficiency with Our Unique Hydraulic Cylinder Catalogue Insights

-

Unleashing Global Potential Small Hydraulic Cylinders from Chinas Leading Manufacturer

-

Exploring the Characteristics and Applications of Best Replacement Hydraulic Cylinders for Global Buyers

-

Solutions for Optimizing Performance with Stainless Steel Hydraulic Cylinders

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.