International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

Innovative Applications of Electric Hydraulic Power Units in Modern Industries

You know, the need for efficiency and power in different industrial sectors has really pushed the development of Electric Hydraulic Power Units, or EHPUs for short. As businesses aim to boost productivity and be more sustainable, switching to electric hydraulic systems fits right in with these goals. A recent report from Grand View Research even says that the global market for electric hydraulic equipment is on track to grow at about 6.5% each year from 2021 to 2028. That just goes to show how much EHPUs are picking up steam in areas like construction, manufacturing, and automotive. And honestly, moving away from traditional hydraulic systems isn’t just a passing fad; it’s a big step towards lowering carbon footprints while also making operations a lot more efficient.

But wait, there’s more! According to Market Research Future, the electric hydraulic systems segment is really expected to take off, and it’s easy to see why. They come with lower maintenance costs and are way more reliable. With Electric Hydraulic Power Units, industries can have precise control and flexible applications, which means they can customize their hydraulic solutions for all sorts of tasks. So, in this piece, we’re diving into the cool stuff that EHPUs can do and how they're changing the game in today's industries, driving innovation and caring for the environment in this fierce market.

Revolutionizing Manufacturing Processes with Electric Hydraulic Power Units

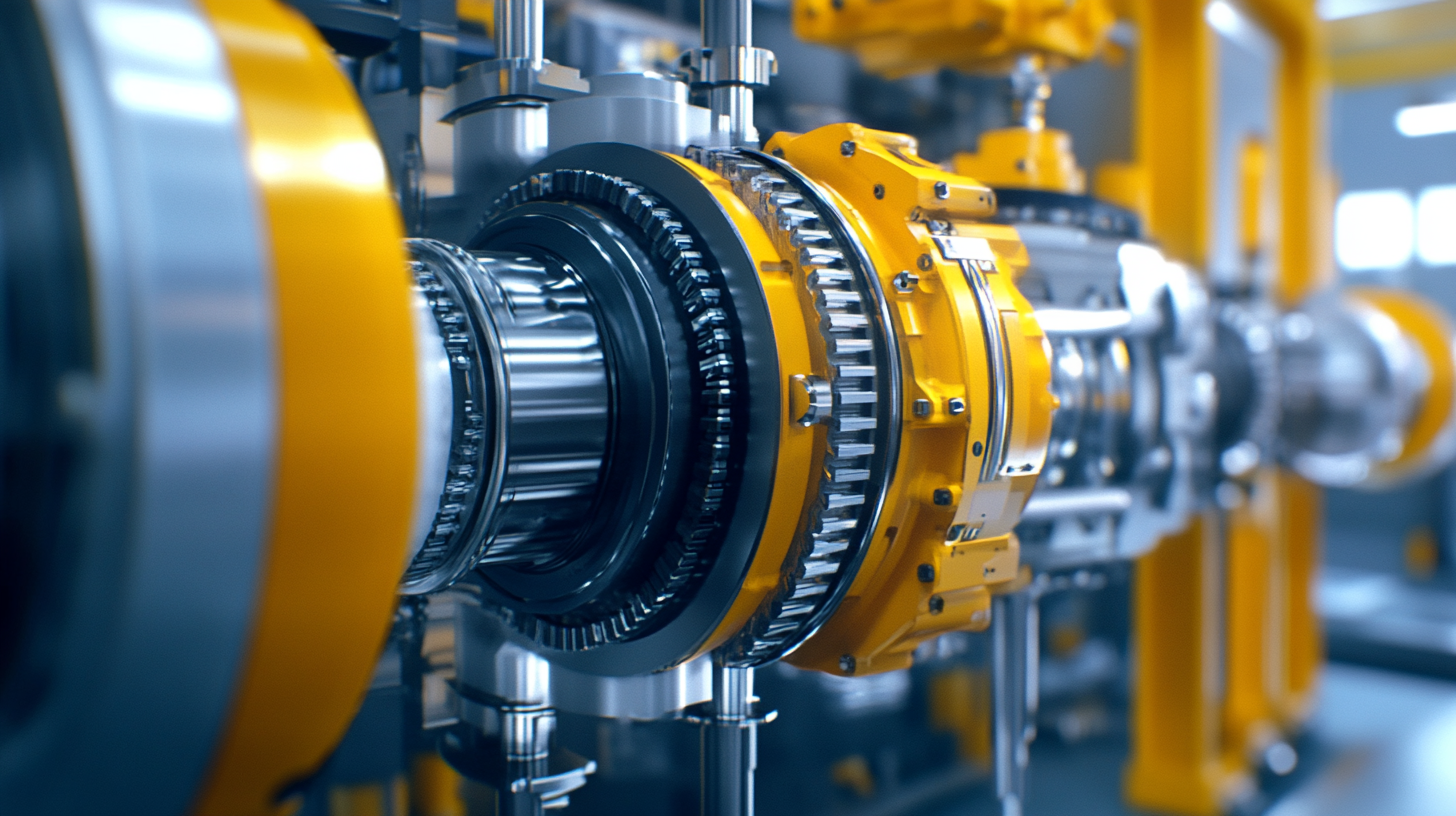

You know, the arrival of electric hydraulic power units (EHPUs) has really changed the game in manufacturing across a bunch of industries. These clever systems mix electric power with hydraulic tech, which means we get way better efficiency, precision, and control in tasks that used to rely on hydraulic pumps running on fossil fuels. It’s a big win for reducing costs, and it also fits in nicely with the global push towards sustainability by cutting down the carbon footprint from manufacturing operations. One of the coolest things about EHPUs is how they’ve transformed automation and robotics in factories. Thanks to their ability to provide consistent hydraulic power whenever needed, robots can now tackle tasks faster and with way more accuracy. This is super helpful in assembly lines, where every little bit of precision counts and getting things done quickly is key. Oh, and their compact design means we can make our workspaces more flexible, which opens up new possibilities for how we set up manufacturing processes. Plus, when you throw EHPUs into the mix, manufacturers can easily adapt and scale up their existing systems without needing major overhauls. This way, they can stay competitive in a market that’s always changing. And let’s not forget about the digital side of things! With smart monitoring and diagnostics, these hydraulic power units allow manufacturers to catch maintenance issues before they turn into headaches, helping them keep production running smoothly and minimizing downtime. As more industries jump on the electric hydraulic bandwagon, it’s becoming super clear just how much potential there is to shake up the traditional manufacturing process.

Efficient Energy Management: The Role of Electric Hydraulic Systems

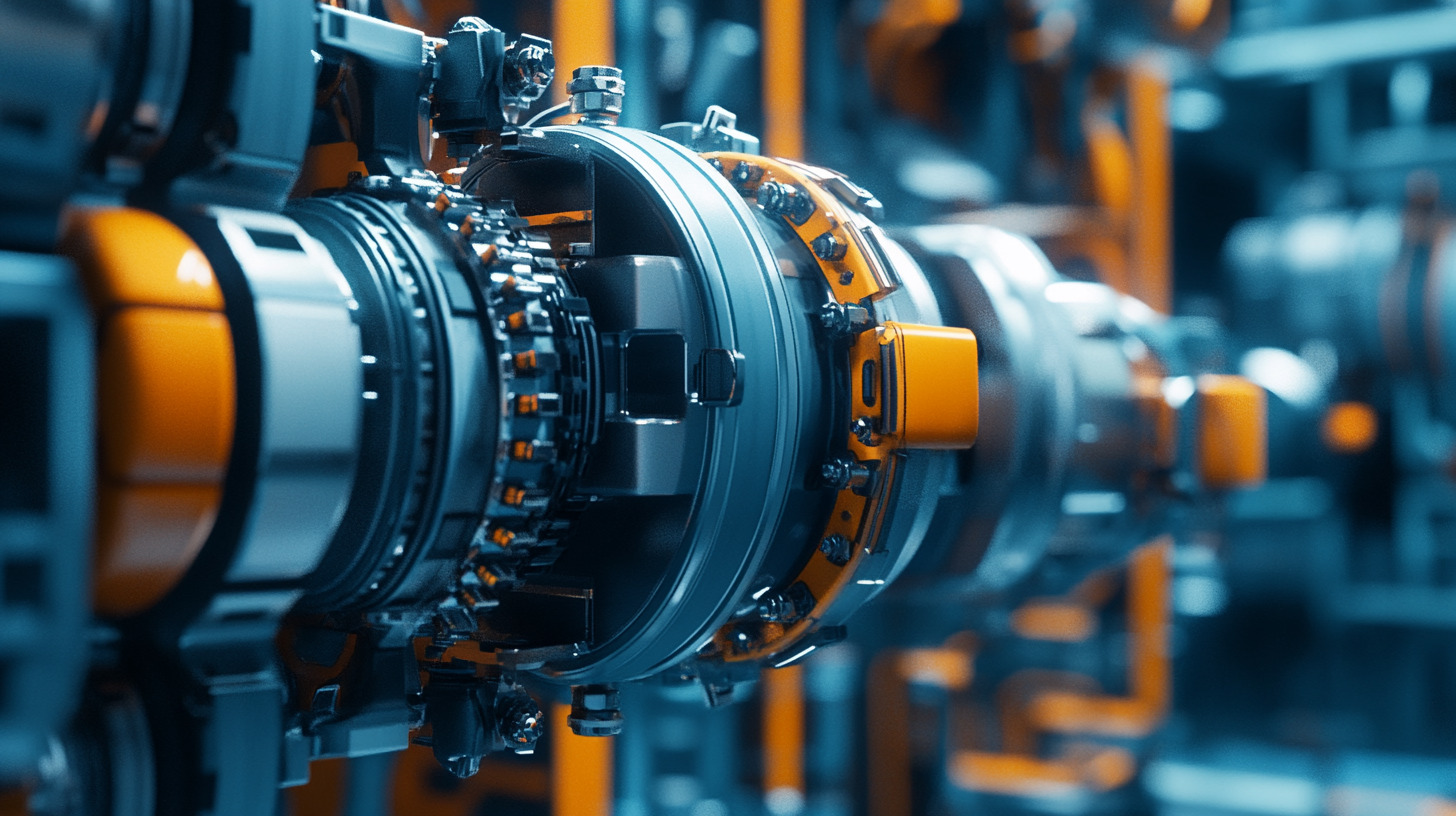

You know, electric hydraulic power units, or EHPUs, are really shaking things up in a lot of modern industries. They’re pretty cool because they use electric motors to power hydraulic pumps, which makes them way more energy-efficient than the older hydraulic systems we used to rely on. According to this report from MarketsandMarkets, the global hydraulic equipment market is expected to hit a whopping USD 52.3 billion by 2025. A big part of that growth is thanks to electric hydraulic systems, which are fantastic at cutting down energy use and operational costs—who doesn’t want that, right?

Now, when it comes to smart vehicles, these electric hydraulic systems are super important for something called Vehicle Motion Control (VMC). This is all about fine-tuning how a vehicle moves, and the electric hydraulic actuators can really step it up—they respond way quicker and more accurately than the old-school mechanical ones. There was even a study in the International Journal of Automotive Technology that said electric hydraulic systems can boost a vehicle’s response time by up to 30%. That's a big deal for both safety and the overall driving experience. Plus, all this energy efficiency not only helps electric vehicles go further but also cuts down on the carbon footprint, aligning nicely with the global push for sustainability.

As we roll with the times, it looks like the use of electric hydraulic power units is only going to grow, especially with all the new tech coming out and energy prices on the rise. More and more businesses are catching on to just how beneficial these systems can be—they help them operate smoother while still meeting those tough environmental standards. By investing in electric hydraulic technologies, industries like automotive and manufacturing are in for some serious gains in energy savings and productivity, steering us towards a greener future.

Innovative Hydraulic Solutions for Sustainable Construction Practices

You know, the construction industry is really going through some big changes lately. Sustainability has become a huge priority for everyone involved. One of the coolest developments has been the rise of these electric hydraulic power units. These innovative solutions are not just about getting the job done more efficiently—they’re also a key player in supporting eco-friendly practices. With these power units, construction companies can control their energy use more precisely and cut down on wasted resources. It’s a win-win: contractors get to lower their carbon footprint without sacrificing productivity.

Enhancing Automation in Automotive Industries through Electric Hydraulics

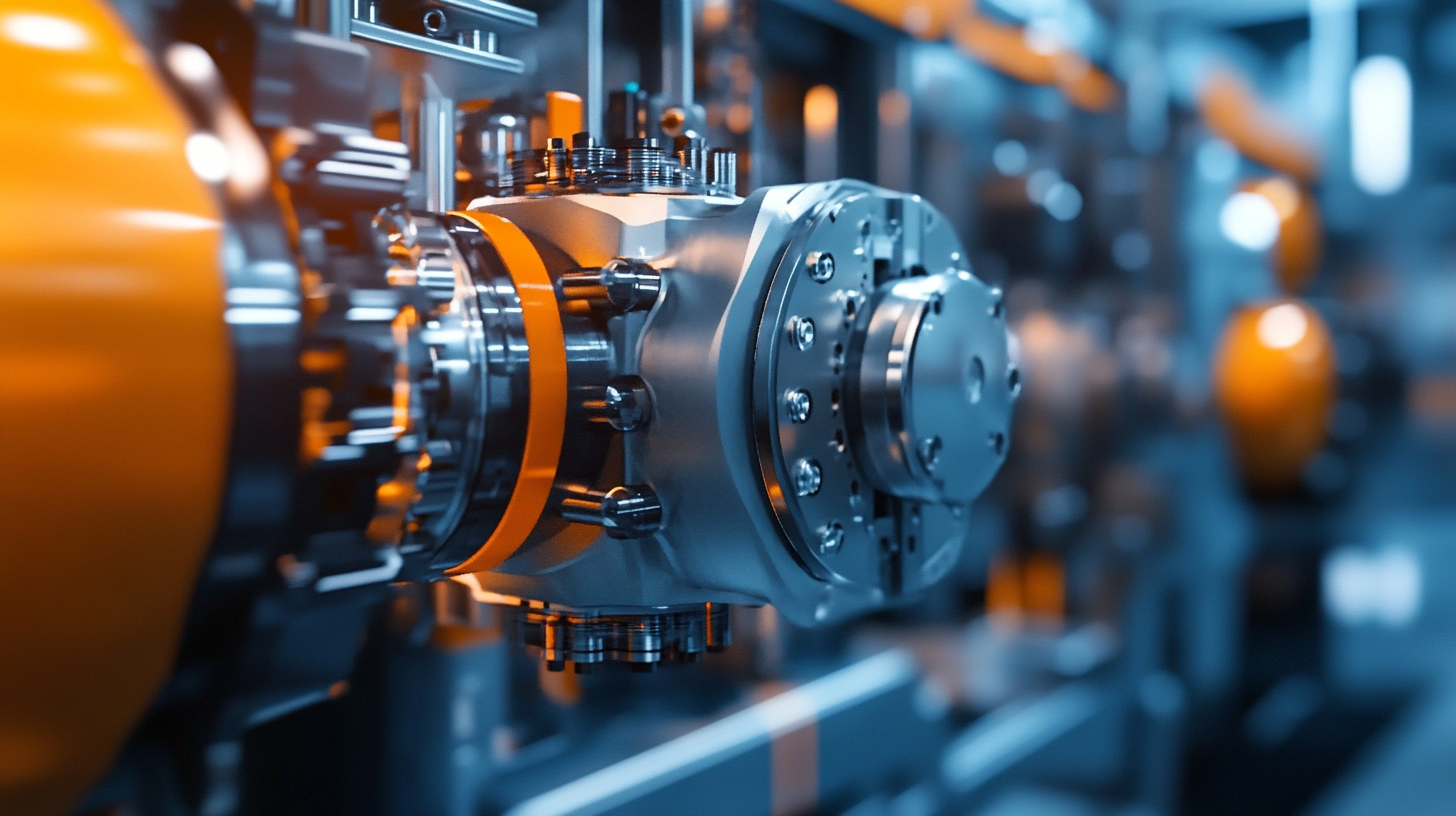

The automotive industry is really going through some exciting changes, and a lot of it has to do with electric hydraulic power units. These bad boys are crucial for upping the game in automation, especially when it comes to manufacturing cars, since they offer super precise control over various mechanical functions. And with the buzz around industrial automation growing, it’s no wonder that electric hydraulic systems are becoming a must-have for boosting efficiency and productivity on those assembly lines.

You know, it’s interesting to see how companies that are diving into electric hydraulics are really starting to thrive. It makes sense, right? They're meeting the shifting demands of today’s manufacturing world. For example, the surge in sales we’re seeing in the hydraulic systems sector clearly shows that folks are looking for innovative solutions that mesh well with their current production setups. Plus, these electric hydraulic power units don't just amp up performance; they're also helping the automotive sector hit its sustainability targets by slashing energy use and emissions.

As everything evolves, it looks like electric hydraulic systems are becoming key players in smart manufacturing. You can see this with the rise of servo electric cylinders and robotic arms—they’re popping up more and more, hinting at a big shift toward more automated and adaptable production processes. This just reinforces how crucial it is for car manufacturers to jump on the electric hydraulics train if they want to stay in the race in this fast-paced market.

Transforming Marine Applications: Electric Hydraulic Power Units in Shipbuilding

You know, when it comes to shipbuilding, there's this game changer that's really shaking things up – electric hydraulic power units, or EHPUs for short. They’re totally rethinking the traditional ways we’ve approached marine applications by making things not just more efficient but also way more sustainable. These high-tech systems give us reliable power for all sorts of jobs, whether it’s hoisting heavy components or maneuvering equipment with pinpoint accuracy. And get this: by swapping out diesel engines for electric motors, EHPUs are helping slash greenhouse gas emissions. It's like the shipbuilding industry is finally steering towards greener technology, which is fantastic, right?

What I really love about EHPUs is how versatile they are. They can fit right into different kinds of machinery, from cranes to winches, making them super effective and even safer to use. Plus, the precise control they offer allows shipbuilders to tackle complex tasks while using less energy and cutting down on noise pollution. This not only makes the production process more efficient but also creates a better work environment for the folks in shipyards. It’s a win-win!

And there's more! Embracing EHPUs is sparking a ton of innovation in how ships are designed and built. With manufacturers keen on rolling out sleeker, more fuel-efficient vessels, these modular power units give builders the flexibility they need to adapt quickly to different projects. This opens up a whole new world of creativity and helps speed up production times. It’s really exciting to see how technology and marine engineering are coming together, making waves in the shipbuilding industry!

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.