International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

Understanding the Functionality of Telescopic Cylinders in Modern Engineering

In modern engineering, the versatility and efficiency of equipment heavily depend on innovative components, with telescopic cylinders emerging as a pivotal element. As reported by the International Journal of Advanced Manufacturing Technology, the global demand for hydraulic systems, which prominently feature telescopic cylinders, is projected to grow at a CAGR of 6.2% through 2025. These multi-stage cylinders are increasingly favored in construction, material handling, and waste management due to their ability to provide substantial linear motion while maintaining a compact profile. With features that accommodate shifting workloads and enhance operational efficiency, the significance of telescopic cylinders in engineering applications cannot be overstated. Understanding their functionality not only reveals insights into their engineering principles but also highlights available alternatives that may optimize specific applications, ultimately contributing to more sustainable and effective design solutions in the modern industry landscape.

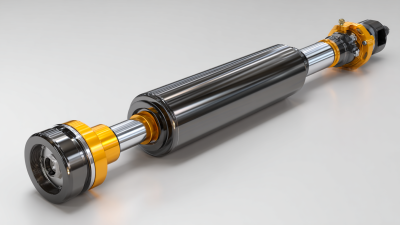

The Basics of Telescopic Cylinders: An Overview of Design and Operation

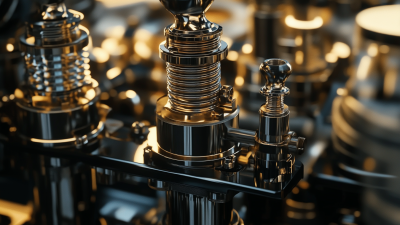

Telescopic cylinders are vital components in modern engineering, particularly in industries requiring compact and powerful linear motion systems. These cylinders are designed to extend and retract by utilizing a series of nested tubes, which allows for significant extension ratios in limited spaces. According to the International Hydraulics Research Institute, the demand for telescopic cylinders has surged by approximately 15% annually, driven by advancements in construction and material handling equipment.

The basic operation of telescopic cylinders involves hydraulic fluid being pumped into the inner tube, pushing it outward and extending the cylinder. This mechanism is not only efficient in terms of space but also provides high load capacity, making it suitable for various applications, including dump trucks, forklifts, and compacting machinery. Research from the Fluid Power Society indicates that using telescopic cylinders can improve machinery performance by up to 25% compared to conventional cylinders of the same size, showcasing their essential role in enhancing operational efficiency in modern engineering projects.

Applications of Telescopic Cylinders in Modern Engineering Solutions

Telescopic cylinders have emerged as a critical component in various modern engineering applications, providing compact solutions for force and motion. These hydraulic or pneumatic devices are designed to extend and retract in stages, making them ideal for scenarios where space is limited. One prominent application is in construction equipment, where telescopic cylinders are employed in cranes and excavators, allowing for greater reach and versatility without compromising the machine's footprint. Their efficient design ensures that heavy loads can be lifted and positioned with precision, enhancing both safety and productivity on job sites.

Telescopic cylinders have emerged as a critical component in various modern engineering applications, providing compact solutions for force and motion. These hydraulic or pneumatic devices are designed to extend and retract in stages, making them ideal for scenarios where space is limited. One prominent application is in construction equipment, where telescopic cylinders are employed in cranes and excavators, allowing for greater reach and versatility without compromising the machine's footprint. Their efficient design ensures that heavy loads can be lifted and positioned with precision, enhancing both safety and productivity on job sites.

In the automotive industry, telescopic cylinders are utilized in various systems, from adjustable seating to automatic liftgates. These cylinders offer the flexibility needed for dynamic applications, enabling easy adjustments while maintaining structural integrity. Furthermore, they are vital in industrial automation, supporting mechanisms that require precise control of movement, such as assembly lines and packaging machinery. By harnessing the functionality of telescopic cylinders, engineers can develop innovative solutions that meet the demands of modern manufacturing and construction environments, driving advancements across multiple sectors.

Advantages of Using Telescopic Cylinders in Industrial Projects

Telescopic cylinders are an integral component in modern engineering, particularly within industrial projects that require robust and adaptable lifting solutions. These cylinders offer the advantage of compactness without sacrificing power, making them ideal for applications in mobile cranes and hoists. According to recent reports, the crane and hoist industry is projected to be worth $41.56 billion by 2030, reflecting the growing demand for efficient lifting technologies. Telescopic cylinders contribute significantly to this market by enabling cranes to extend their reach while maintaining a smaller footprint.

Additionally, the hydraulic cylinder market is experiencing notable growth, with an estimated value of $14.3 billion in 2021, projected to reach $18.3 billion by 2027. This growth underscores the critical role that advanced hydraulic systems, including those featuring telescopic cylinders, play in industrial applications. By enhancing lifting capacity and improving maneuverability, telescopic cylinders not only meet the high requirements of modern engineering but also drive innovation in machinery design, paving the way for safer and more efficient operations in various sectors. As technology continues to evolve, the benefits of using telescopic cylinders will only become more pronounced, further solidifying their position in the industrial landscape.

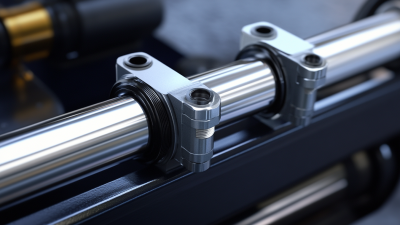

Maintenance Best Practices for Optimal Performance of Telescopic Cylinders

Telescopic cylinders are essential components in various industries, providing significant advantages in space-saving designs and power efficiency. To ensure optimal performance and longevity, adherence to maintenance best practices is crucial. Regular inspection and maintenance can dramatically reduce the risk of hydraulic failures; according to a report by the International Journal of Fluid Power, up to 40% of hydraulic system failures can be attributed to inadequate maintenance.

Routine checks should include evaluating seals, lubrication levels, and the condition of the cylinder's outer surfaces. It’s recommended to clean the cylinders regularly to prevent dirt and contaminants from entering the hydraulic system, as studies have shown that contamination accounts for nearly 70% of hydraulic failures. Additionally, implementing a proactive maintenance schedule can enhance performance, as noted in the NAHAD Hydraulics Report, which cites a 25% increase in efficiency in systems that followed structured maintenance programs. This not only extends the lifespan of telescopic cylinders but also contributes to overall machinery reliability in demanding applications.

Future Trends in Telescopic Cylinder Technology and Innovation

The future of telescopic cylinder technology is poised for significant evolution, driven by advancements in materials science and automation. As industries seek lighter, more durable components, innovations such as composite materials are being integrated into telescopic cylinder design. These materials not only enhance the strength-to-weight ratio but also reduce corrosion, making cylinders more efficient for long-term use in environments that challenge traditional metal counterparts. With the growing emphasis on sustainability, these innovations aim to create products that are not only high-performing but also environmentally friendly.

Moreover, the integration of smart technology into telescopic cylinders is revolutionizing their functionality. Sensors and IoT (Internet of Things) capabilities are being embedded within these systems, allowing for real-time monitoring of performance and efficiency. This connectivity can lead to predictive maintenance, reducing downtime and improving overall operational efficiency. As industries push for more automation, the role of intelligent telescopic cylinders is anticipated to expand, paving the way for systems that are not only automated but also flexible and responsive to dynamic working environments.

Understanding the Functionality of Telescopic Cylinders in Modern Engineering - Future Trends in Telescopic Cylinder Technology and Innovation

| Dimension | Current Technology | Future Trends | Potential Applications |

|---|---|---|---|

| Material Composition | Steel and Aluminum | Advanced Composites | Automotive and Aerospace |

| Operating Pressure | Up to 300 bar | 400 - 600 bar | Construction Equipment |

| Control Systems | Hydraulic Valves | Smart Sensors and IoT Integration | Robotics and Automation |

| Size Range | Up to 12 meters | Expandable Designs | Heavy Machinery |

| Efficiency | Standard Efficiency | High-Efficiency Hydraulics | Energy Recovery Systems |

Related Posts

-

Mastering the Art of Selecting the Best Hydraulic Piston for Your Business Needs

-

The Comprehensive Handbook to Designing Your Own Custom Hydraulic Cylinders

-

2025 Insights: How Advanced Materials are Revolutionizing the Best Hydraulic Cylinder Industry

-

Solutions for Optimal Hydraulic Cylinder Tools Efficiency

-

Unlocking Efficiency: The Ultimate Guide to Selecting the Right Hydraulic Power Pack for Your Needs

-

Mastering the Use of Best Mini Hydraulic Cylinder for Your Projects

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.