International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

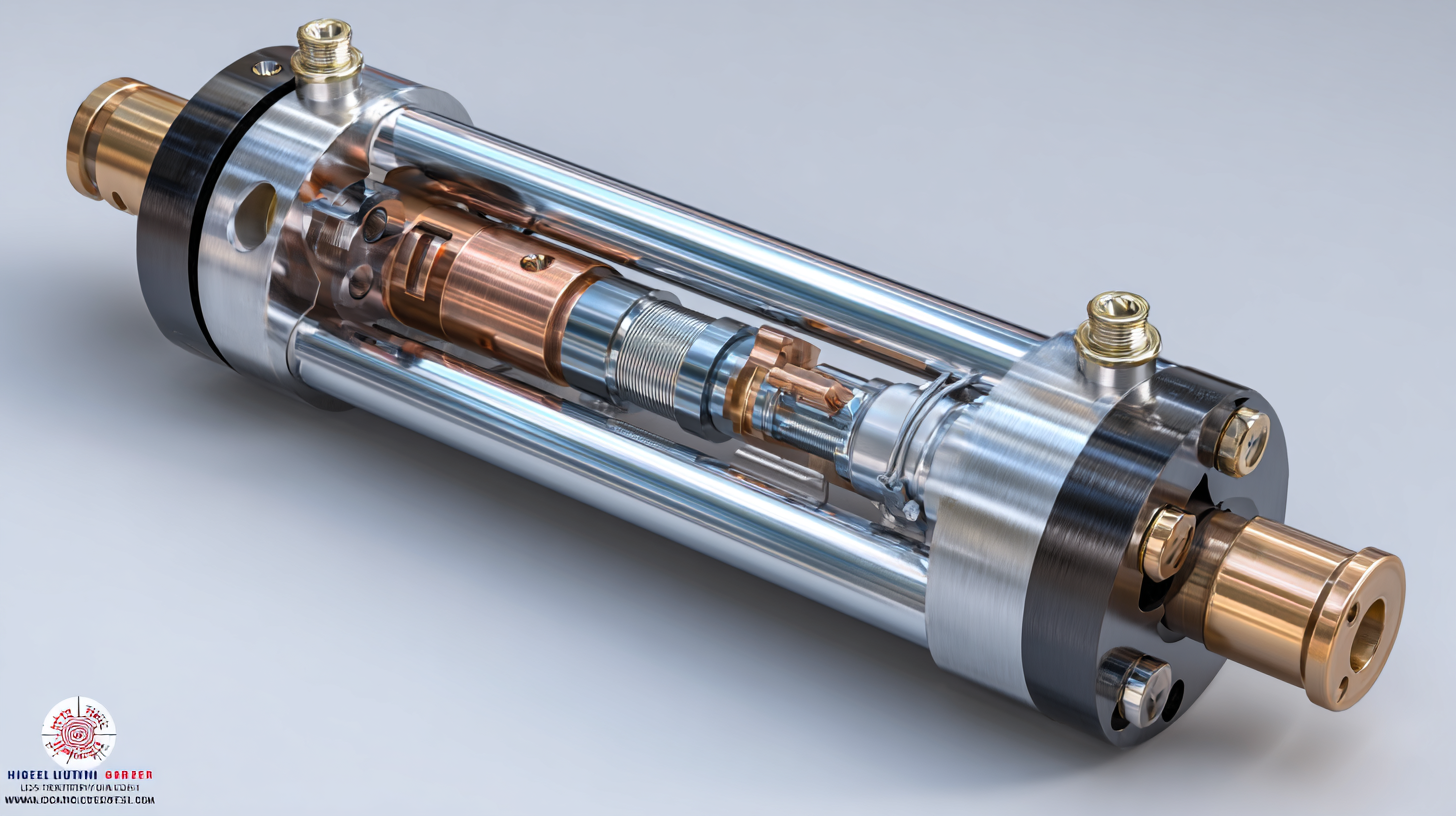

Global Market Insights on Best Custom Hydraulic Cylinders by 2025 with Tips for Savvy Buyers

The demand for Custom Hydraulic Cylinders is projected to increase significantly in the coming years, driven by advancements in automation and a renewed focus on industrial efficiency. According to a recent report by MarketsandMarkets, the global hydraulic cylinders market is expected to reach $12.5 billion by 2025, growing at a CAGR of 5.6%. As industries strive to enhance performance and reduce operational costs, the customization of hydraulic cylinders becomes essential to meet specific application needs. Savvy buyers are therefore presented with a unique opportunity to maximize their investments by understanding the latest market trends and leveraging best practices in sourcing these critical components. This blog will explore essential insights on the custom hydraulic cylinders market and provide valuable tips for making informed purchasing decisions.

Trends Shaping the Custom Hydraulic Cylinder Market by 2025

The custom hydraulic cylinder market is poised for significant growth as we approach 2025, driven by emerging trends and evolving consumer demands. One of the key trends influencing this market is the ongoing push for automation and efficiency across various industries, including construction, manufacturing, and aerospace. As companies seek high-performance solutions to meet rigorous operational standards, customized hydraulic cylinders, which can be tailored to specific applications, are increasingly in demand.

Furthermore, sustainability is becoming a pivotal factor for buyers in the hydraulic cylinder market. With an emphasis on reducing environmental impact, manufacturers are focusing on creating more energy-efficient and environmentally friendly hydraulic systems. This trend not only helps industries meet regulatory standards but also appeals to a growing consumer base that prioritizes sustainability.

Savvy buyers are encouraged to consider these factors—automation capabilities and sustainability efforts—when selecting custom hydraulic cylinders, ensuring that their investments not only fulfill current needs but also align with future industry developments.

Key Factors Driving Demand for Custom Hydraulic Cylinders Globally

The demand for custom hydraulic cylinders is surging globally, driven by several key factors including advancements in technology and increased applications across various industries. According to a market research analysis, the global industrial hydraulic equipment market is projected to grow from $26.13 billion in 2023 to $35.92 billion by 2030, marking a CAGR of 4.7%. This growth indicates a robust trend that custom hydraulic cylinder manufacturers can leverage to meet specific performance requirements across sectors such as construction, manufacturing, and logistics.

As the hydraulic cylinder market continues to evolve, forecasts suggest it will reach an estimated value of USD 18.3 billion by 2027, growing at a CAGR of 4.4% from 2025 to 2030. With this expansion, savvy buyers are encouraged to consider factors such as customization capabilities, quality assurance, and supplier reliability when selecting hydraulic solutions. Understanding market dynamics and trends will empower buyers to make informed decisions that align with their operational needs, ultimately enhancing performance and efficiency in their applications.

5 Essential Features to Look for in Quality Hydraulic Cylinders

When searching for quality hydraulic cylinders, savvy buyers should prioritize several essential features that ensure optimal performance and longevity. First and foremost, the material used in the cylinder construction plays a critical role. High-strength steel alloys are preferred for their durability and resistance to wear and corrosion, which can significantly extend the lifespan of the cylinder in demanding environments.

Additionally, the seal design is another crucial aspect to consider. Quality hydraulic cylinders should feature advanced sealing systems that prevent leaks and allow for smooth operation under pressure. Look for seals made from high-grade materials that can withstand extreme temperatures and harsh conditions, as this will directly impact the efficiency of your hydraulic system.

Lastly, the compatibility and customization options of hydraulic cylinders are vital. Ensure that the cylinders can be tailored to fit your specific machinery or application needs. The ability to access various sizes, stroke lengths, and mounting styles can make a significant difference in performance and functionality, offering buyers the versatility they require for their unique projects.

Global Market Insights on Best Custom Hydraulic Cylinders by 2025

| Feature | Description | Importance | Market Trend |

|---|---|---|---|

| Material Quality | Durable and corrosion-resistant materials like high-strength steel. | Ensures longevity and reliability in harsh environments. | Increasing demand for durable industrial equipment. |

| Seal Design | Advanced sealing solutions to prevent leaks. | Vital for maintaining pressure and performance. | Shift towards more efficient hydraulic systems. |

| Customization Options | Ability to tailor dimensions and specifications to specific needs. | Enhances compatibility and performance in unique applications. | Growing trend of bespoke engineering solutions. |

| Pressure Ratings | High pressure tolerance to suit various industrial uses. | Critical for operations that require high force transfer. | Increasing use in heavy machinery and construction projects. |

| Size and Weight | Compact design while maintaining robustness. | Facilitates ease of installation and operation. | Trend towards lightweight yet powerful hydraulic solutions. |

Tips for Savvy Buyers: How to Choose the Right Manufacturer

When considering the purchase of custom hydraulic cylinders, savvy buyers should prioritize a thorough evaluation of manufacturers. According to recent industry reports, the global hydraulic cylinder market is projected to reach $18.6 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.3% from 2020. This growth highlights the increasing demand for precision-engineered hydraulic solutions across various sectors, from construction to aerospace. Buyers must assess manufacturers based on their quality certifications, industry experience, and technological capabilities to ensure they receive a product that meets rigorous performance standards.

Additionally, with hydraulic systems being critical for efficiency and safety, buyers should inquire about the manufacturer’s material sourcing and production techniques. A noteworthy aspect is that about 60% of hydraulic cylinder failures are attributed to poor fabrication practices. Therefore, choosing a manufacturer that utilizes advanced manufacturing technologies, such as Computer Numerical Control (CNC) machining, can significantly enhance the durability and reliability of the cylinders. Furthermore, a supplier’s commitment to after-sales support and service can be a crucial differentiator, ensuring that customers receive reliable assistance throughout the lifecycle of their hydraulic systems.

The Impact of Technological Advancements on Hydraulic Cylinder Designs

The impact of technological advancements on hydraulic cylinder designs is reshaping the landscape of the global market, which was valued at $10.94 billion in 2018 and is projected to reach $19.77 billion by 2032. Innovations in material science and engineering have led to the development of more efficient and durable hydraulic cylinders that meet the increasing demands of various industries. These advancements not only enhance the performance of hydraulic systems but also contribute to energy savings and reduced maintenance costs.

With the shift towards automation and smart technologies, manufacturers are increasingly integrating IoT capabilities into hydraulic cylinders. This allows for real-time monitoring, enabling predictive maintenance and reducing downtime. As a savvy buyer, it is essential to consider these technological features when selecting custom hydraulic cylinders. Understanding the advancements in design and functionality will empower buyers to make informed decisions, ensuring that their investments align with future industry standards while maximizing operational efficiency.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.