International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

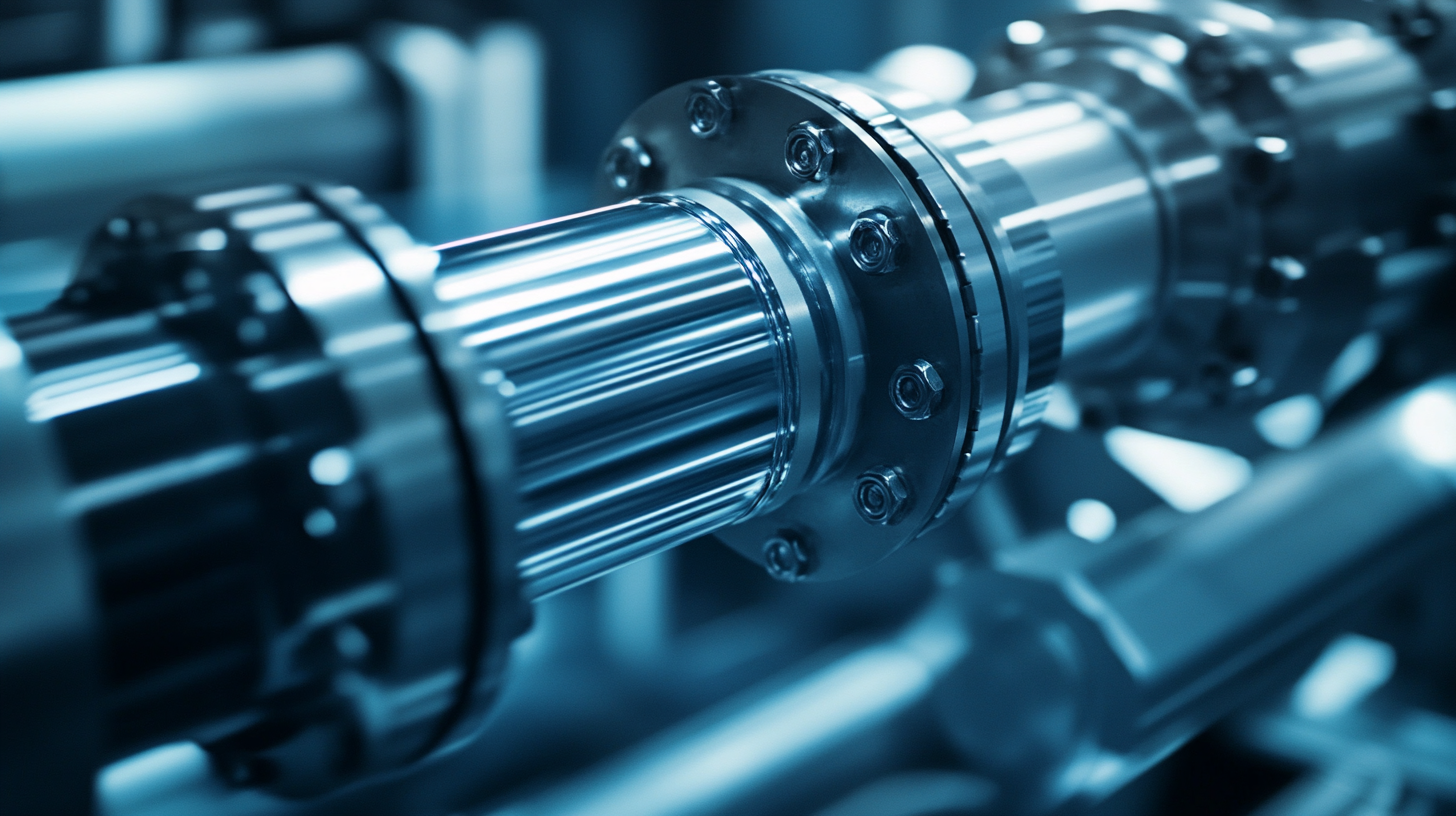

Hydraulic Cylinder Tools Trends Shaping the Future of Global Procurement in 2025

In recent years, the global market for Hydraulic Cylinder Tools has experienced significant transformation, influenced by advancements in technology and evolving procurement strategies. According to a report by MarketsandMarkets, the hydraulic cylinder market is projected to reach $11.9 billion by 2025, with a compound annual growth rate (CAGR) of 4.1%. This growth highlights the increasing reliance on hydraulic systems across various industries, including construction, manufacturing, and automotive. As organizations strive for enhanced operational efficiency and cost-effectiveness, understanding the latest trends in hydraulic cylinder tools becomes imperative for procurement professionals.

Furthermore, the integration of smart technologies within hydraulic systems is revolutionizing the way hydraulic cylinder tools are perceived and utilized. The advent of IoT and automation is enabling real-time monitoring and maintenance, thus drastically improving the lifecycle management of these tools. The Industry 4.0 paradigm emphasizes data-driven decision-making, allowing companies to optimize their supply chains and procurement processes. As we move towards 2025, businesses must adapt to these changes, ensuring they leverage innovative hydraulic cylinder tools that will not only meet their operational demands but also provide a competitive edge in an increasingly dynamic market.

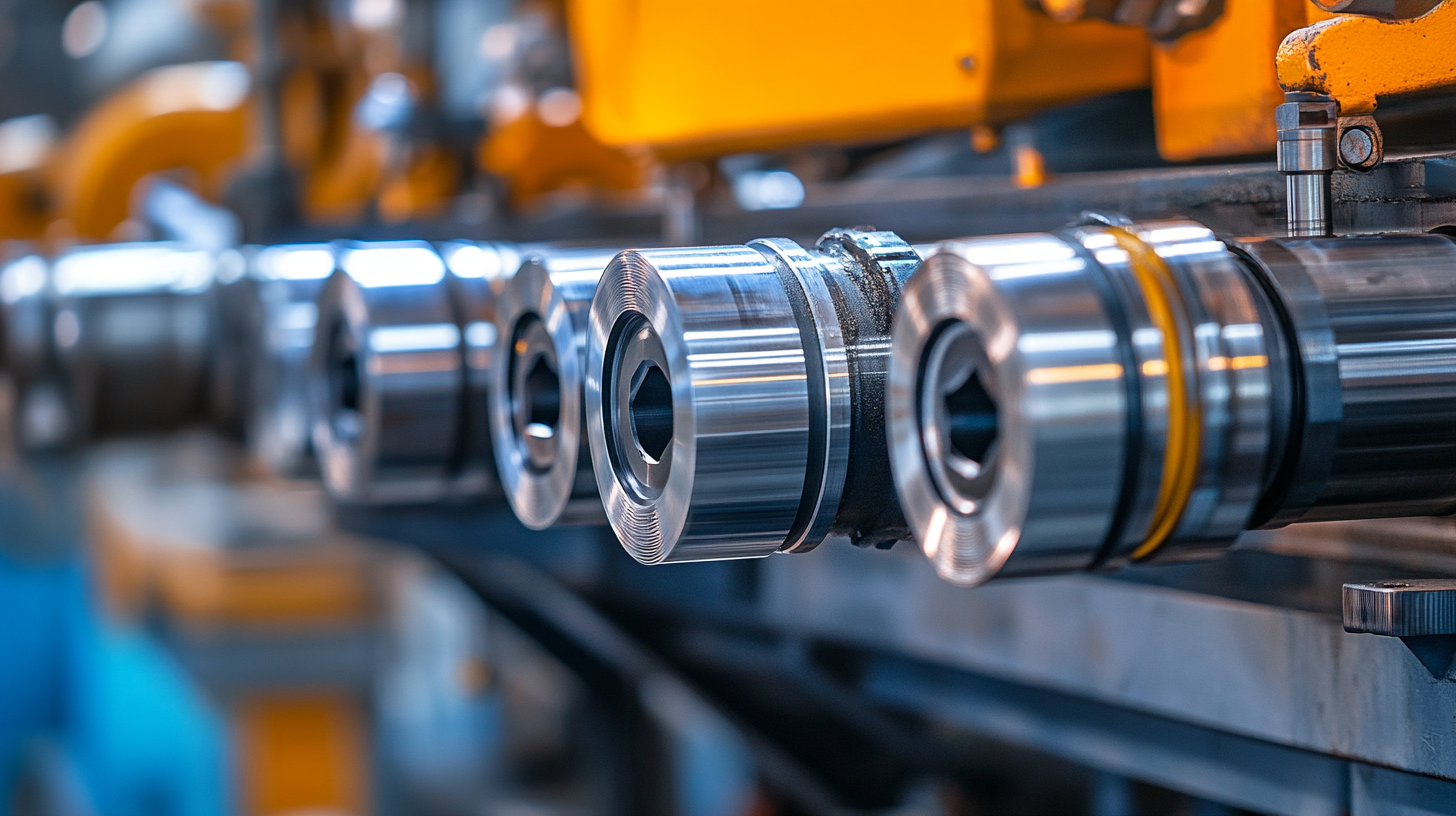

Emerging Technologies Transforming Hydraulic Cylinder Tool Manufacturing

The manufacturing of hydraulic cylinder tools is undergoing a transformative shift, driven by emerging technologies that are reshaping the production landscape. As the global market for hydraulic cylinders is projected to reach approximately $19.46 billion by 2025, the integration of advanced manufacturing technologies is crucial for meeting increasing demands efficiently. Innovations in materials and design, such as the use of lightweight, high-strength composites, are enhancing the performance and durability of hydraulic cylinders, enabling them to withstand higher pressures and operational stresses. In addition to materials innovation, automation and smart technology are revolutionizing production processes. The adoption of Industry 4.0 principles, including IoT integration and advanced robotics, is streamlining operations and improving precision in manufacturing. For instance, the implementation of predictive maintenance systems can significantly reduce downtime and increase the lifespan of hydraulic equipment, which is particularly vital in sectors like construction and agriculture where reliability is paramount. Furthermore, geopolitical factors are influencing procurement strategies, prompting manufacturers to focus on self-reliance in technology. A notable example is China's recent advancement in producing a massive pile-driving cylinder, reinforcing its commitment to enhancing domestic production capabilities. This trend is expected to steer procurement strategies globally, necessitating a focus on local suppliers capable of meeting stringent quality and technological standards. As the hydraulic cylinder tools market evolves, stakeholders must navigate these technological advances strategically. Investing in research and development will be essential for companies aiming to maintain competitiveness and meet the rising expectations of end-users across various industries.

Sustainable Practices Driving Global Procurement Strategies in 2025

In 2025, the landscape of global procurement for hydraulic cylinder tools is set to evolve significantly, driven by an increased focus on sustainable practices. As industries face mounting pressure to reduce their environmental footprint, procurement strategies are being re-evaluated. Companies are not only searching for cost-effective solutions but are also prioritizing suppliers that embrace sustainability, fostering a circular economy through eco-friendly materials and practices.

This shift towards sustainability is evident in the growing demand for hydraulic cylinder tools designed with energy efficiency in mind. Manufacturers are innovating by integrating smart technologies that optimize performance and minimize waste. For instance, the use of recycled materials in production processes not only conserves resources but also appeals to environmentally conscious consumers. As a result, suppliers that invest in these green technologies will likely gain a competitive edge in the global market.

Additionally, collaboration between various stakeholders is becoming crucial in achieving sustainable procurement goals. Businesses are forming strategic partnerships with vendors, focusing on transparency and sustainable sourcing methods. By sharing best practices and developing joint initiatives, companies can enhance their supply chain resilience while promoting shared responsibility for environmental impacts. As we move towards 2025, the alignment of procurement strategies with sustainable development goals will not only meet regulatory requirements but will also elevate brand reputation and drive long-term success.

The Role of Automation in Optimizing Hydraulic Cylinder Production

The future of hydraulic cylinder production is being significantly shaped by advancements in automation. With a projected market growth rate of 4.6% per year, the global hydraulic cylinders market is expected to reach approximately $18 billion by 2025, according to market research reports. Automation not only streamlines manufacturing processes but also enhances precision, reduces waste, and ensures consistent quality in production. Companies that incorporate automated tools are already witnessing improvements in operational efficiency and a decrease in production times, which are critical in meeting rising demand.

As manufacturers adopt Industry 4.0 principles, the integration of IoT (Internet of Things) devices into hydraulic cylinder production lines is becoming increasingly common. These technologies facilitate real-time monitoring and predictive maintenance of equipment, reducing unexpected downtimes by up to 30%, as reported by top industry analyses. Additionally, advanced robotics and AI-driven processes are enabling more customizable production options, allowing companies to quickly adapt to market trends and specific client requirements.

Furthermore, the use of automation is not limited to the production stage; it extends to supply chain management and procurement strategies as well. The application of automated procurement tools can lead to cost savings of approximately 20%, as they enhance inventory control and supplier management. As the hydraulic cylinder sector continues to innovate, those who leverage automation will likely lead the market in providing high-quality, efficient, and competitively priced solutions.

Future Market Dynamics: Demand Trends for Hydraulic Cylinder Tools

The future of global procurement for hydraulic cylinder tools is poised for significant transformation by 2025, driven by evolving demand trends. According to a recent market research report, the global hydraulic cylinder market size is expected to reach approximately USD 10.5 billion by 2025, growing at a CAGR of around 5.2%. This growth is largely attributed to the increasing automation in various industries, including construction, manufacturing, and agriculture, which rely heavily on efficient hydraulic systems.

Specifically, the demand for hydraulic cylinder tools is being shaped by the rise of electric and hybrid machinery in industrial applications, as companies seek to enhance efficiency and reduce operational costs. A report from Markets and Markets indicates that the adoption of advanced hydraulic technologies is projected to increase by 15% annually, as industries prioritize enhanced performance and reliability in their hydraulic systems. Furthermore, the emphasis on sustainable practices is driving the development of greener hydraulic solutions, which presents new opportunities for suppliers and manufacturers alike.

Additionally, the ongoing trend toward digital transformation and smart manufacturing is influencing procurement strategies within the hydraulic cylinder tools market. A study by Technavio suggests that the integration of IoT and smart devices in hydraulic systems can lead to improved predictive maintenance, reducing downtime and operational inefficiencies. With these innovations, procurement professionals must adapt to sourcing smart, connected hydraulic solutions that align with the modern industry's shifting demands and technological advancements.

Innovative Materials Leading the Way in Hydraulic Cylinder Development

The evolution of hydraulic cylinders has been significantly influenced by innovative materials that are redefining their design and functionality. As industries seek to enhance efficiency and performance, the shift towards lightweight, durable materials like advanced composites and alloys has become paramount. These materials not only improve the overall strength and longevity of hydraulic cylinders but also contribute to reducing operational costs, making them a focal point in global procurement strategies for 2025.

Moreover, industry leaders are recognizing the need for digital transformation in manufacturing processes. By integrating new materials with cutting-edge technologies, companies can streamline production and enhance product innovation. Recent initiatives, such as training and exchange programs for entrepreneurs, highlight the importance of fostering collaboration and sharing knowledge to drive this transformation. As businesses adapt to these trends, the focus on innovative materials will undoubtedly play a crucial role in maintaining competitiveness in the global market.

In parallel, stories of individual innovation, such as those shared by exemplary workers in technology sectors, inspire a culture of exploration and problem-solving. These narratives remind us that advancements often arise from unexpected places and that an environment conducive to creativity is essential for breakthroughs. The combination of innovative materials and a nurturing landscape for innovation will shape the future of hydraulic cylinder development, leading to smarter, more efficient solutions in a rapidly evolving industry.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.