International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

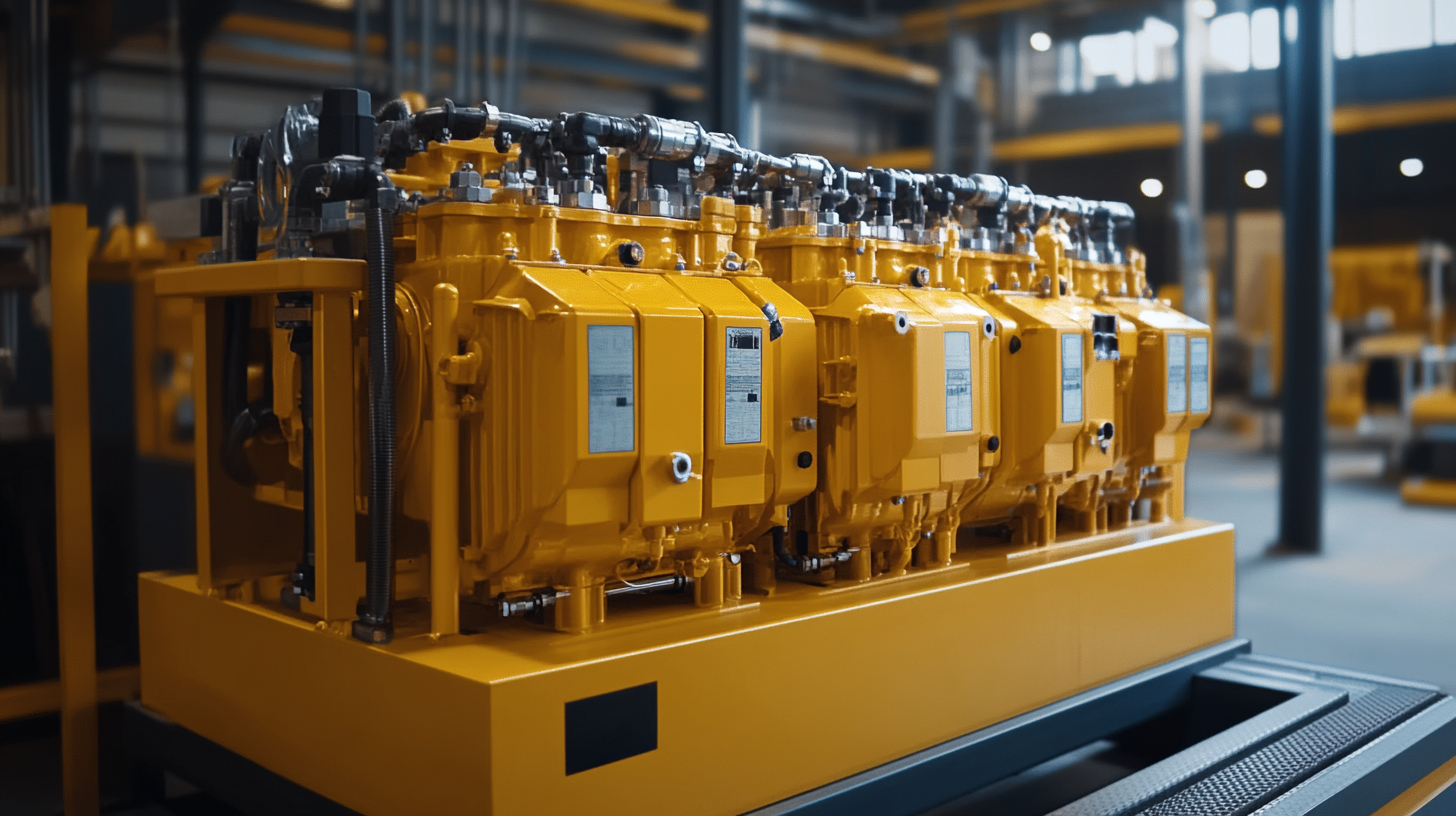

Unlocking Efficiency: The Ultimate Guide to Selecting the Right Hydraulic Power Pack for Your Needs

In today's fast-paced industrial landscape, maximizing efficiency is essential for success, and one of the key components that can significantly enhance operational performance is the Hydraulic Power Pack. This versatile device acts as the heart of hydraulic systems, supplying the necessary power to drive various machinery and equipment. However, with a plethora of options available on the market, selecting the right Hydraulic Power Pack for your specific needs can be a daunting task. Factors such as flow rate, pressure requirements, and compatibility with existing systems must be carefully considered to ensure optimal performance. In this comprehensive guide, we will delve into the intricacies of Hydraulic Power Packs, providing valuable insights and expert tips to help you make an informed decision. Whether you're a seasoned engineer or a novice in hydraulic technology, our goal is to empower you with the knowledge needed to unlock the full potential of your operations through the right Hydraulic Power Pack selection.

Understanding the Fundamentals of Hydraulic Power Packs and Their Applications

Hydraulic power packs are essential components in various industrial applications, delivering power and control through hydraulic fluid. Understanding their fundamentals is crucial for effective selection and application. A hydraulic power pack consists of a power source—usually an electric motor or an engine, a hydraulic pump, and a reservoir. These components work together to convert mechanical energy into hydraulic energy, allowing machines to perform heavy lifting, precise movements, or other tasks that require significant force.

The versatility of hydraulic power packs makes them suitable for a wide range of applications. In construction, they power equipment such as excavators and loaders, enabling operators to exert substantial force with minimal effort. In manufacturing, hydraulic systems facilitate the operation of presses and conveyors, improving productivity and efficiency. Additionally, sectors like aviation and agriculture rely on hydraulic power for various operations, from airplane movements on the tarmac to lifting heavy loads in farming equipment. By grasping the basics of how hydraulic power packs function and their potential applications, users can make informed decisions that enhance their operational efficiency and effectiveness.

Key Factors to Consider When Choosing a Hydraulic Power Pack for Your Project

When it comes to selecting a hydraulic power pack for your project, several key factors should guide your decision-making process. First and foremost, understanding the required pressure and flow rate is crucial. These specifications will dictate the efficiency of your hydraulic system. Evaluate the demands of your application: are you powering simple tools or operating complex machinery? Knowing the operational requirements will help you identify a unit that offers both performance and reliability.

Another critical aspect to consider is the power source. Hydraulic power packs can be powered by electric, gasoline, or diesel engines, each offering different advantages. Electric units are quieter and more energy-efficient, while gas or diesel-powered packs typically provide greater portability, making them ideal for outdoor or remote applications. Additionally, assess the size and weight of the unit. A compact and lightweight design can be beneficial for projects with space constraints or for those requiring easy transport.

Finally, maintenance requirements and serviceability should not be overlooked. Opt for a hydraulic power pack that offers easy access to components and comes with a solid warranty and support services. Reliability is paramount in hydraulic systems, so investing in quality equipment with robust customer support can save time and resources in the long run. Taking these factors into account will help ensure you select a hydraulic power pack that perfectly aligns with your project's specific needs.

Comparing Different Types of Hydraulic Power Packs: Pros and Cons

When it comes to selecting the right hydraulic power pack for your projects, understanding the nuances of different types is crucial. Hydraulic power packs generally fall into three categories: electric, diesel, and hand-operated systems. Each type has its unique set of advantages and disadvantages that can significantly impact your operational efficiency.

Electric hydraulic power packs are renowned for their quiet operation and ease of use, making them ideal for indoor applications. They provide consistent power output and require minimal maintenance. However, their reliance on electricity may restrict usage in outdoor or remote environments where power sources are not readily available. On the other hand, diesel hydraulic power packs offer mobility and independence from electrical sources, which is invaluable in outdoor applications. However, they tend to produce more noise and emissions, which can be a drawback in sensitive environments.

Hand-operated hydraulic power packs, while the least common, are favored for their simplicity and cost-effectiveness. They are suitable for light-duty tasks and can be easily transported. Nonetheless, their manual operation can be labor-intensive and impractical for larger or more complex projects. By weighing these pros and cons, one can make a well-informed decision that best suits their specific hydraulic power requirements.

Maintenance Tips for Prolonging the Life of Your Hydraulic Power Pack

Maintaining the efficiency and longevity of your hydraulic power pack is crucial for ensuring optimal productivity and performance in various applications. Regular maintenance practices can significantly extend the life of hydraulic systems, which are vital for operations like liftgates that enhance loading and unloading safety and efficiency. Studies suggest that preventative maintenance can reduce hydraulic system failures by over 50%, underscoring the importance of a proactive approach.

One effective strategy is the integration of advanced filtration systems, such as magnetic filtration technology, which captures contaminants of all sizes and protects the hydraulic fluid from damage. In fact, systems utilizing such pre-filter solutions can see a marked improvement in operational lifespan and reliability. Additionally, adherence to proper operating techniques and routine checks, including fluid levels and connection integrity, can further enhance the performance of hydraulic attachments like vibratory rollers and breakers, allowing them to serve effectively for many years in demanding environments.

Hydraulic systems, when maintained properly, not only facilitate smoother operations but also safeguard substantial investments in machinery. Proper lubrication and timely servicing can lead to significant cost savings by minimizing downtime and replacement needs. Thus, it’s essential for operators to implement a comprehensive maintenance plan tailored to their hydraulic power pack's specific requirements for sustained operational excellence.

Hydraulic Power Pack Maintenance Tips

Expert Recommendations for Sizing Your Hydraulic Power Pack Appropriately

When it comes to selecting the right hydraulic power pack for your applications, appropriate sizing is crucial for ensuring optimal performance and efficiency. A well-sized power pack not only enhances productivity but also contributes to the longevity of your machinery. As the demand for hydraulic power solutions increases, particularly in the automotive sector, understanding how to choose the right components becomes essential. Experts advise considering factors such as flow rate, pressure requirements, and the type of actuators being used.

With the recent surge in the automotive actuators market, projected to reach USD 107.86 billion by 2034, understanding these parameters can lead to significant cost savings and improved efficiency. A properly sized hydraulic power pack ensures that actuators operate smoothly, minimizing energy wastage and reducing wear and tear. By leveraging expert recommendations and keeping abreast of industry trends, users can make informed decisions that cater to their specific needs while aligning with the growth trajectories of related markets.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.