International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

Mastering the Use of Best Mini Hydraulic Cylinder for Your Projects

In the ever-evolving landscape of industrial applications, the demand for compact and efficient solutions has never been greater. According to a recent market analysis by Research and Markets, the global hydraulic cylinder market is projected to reach USD 18.67 billion by 2025, with mini hydraulic cylinders playing a pivotal role in this growth. These versatile components are integral to a variety of sectors, including construction, automotive, and manufacturing, due to their ability to deliver high force in confined spaces. As industries strive for enhanced performance and space optimization, mastering the use of mini hydraulic cylinders is essential for achieving project efficiency and effectiveness. This blog will explore various case studies illustrating their successful application across different industries, providing valuable insights for professionals looking to leverage mini hydraulic cylinders in their projects.

Understanding the Different Types of Mini Hydraulic Cylinders

When it comes to mini hydraulic cylinders, understanding the different types available is crucial for effectively utilizing them in your projects. Mini hydraulic cylinders are compact yet powerful devices that can provide significant force in tight spaces. The primary types include single-acting and double-acting cylinders. Single-acting cylinders use hydraulic pressure in one direction only, relying on a spring or gravity to return to their original position. This is ideal for applications requiring a simple push movement, such as lifting or holding a load.

On the other hand, double-acting cylinders are versatile, allowing for movement in both directions by using hydraulic pressure for both extending and retracting. This design is perfect for situations that demand more control and precision, such as in automated machinery or robotics. Additionally, there are specialized types, such as telescopic cylinders, which can extend significantly beyond their initial size, making them ideal for lifting heavy objects in a limited area. By understanding these various types of mini hydraulic cylinders, you can select the right one for your specific project needs, ensuring efficiency and effectiveness in your applications.

Understanding the Different Types of Mini Hydraulic Cylinders

Key Features to Look for in a Mini Hydraulic Cylinder

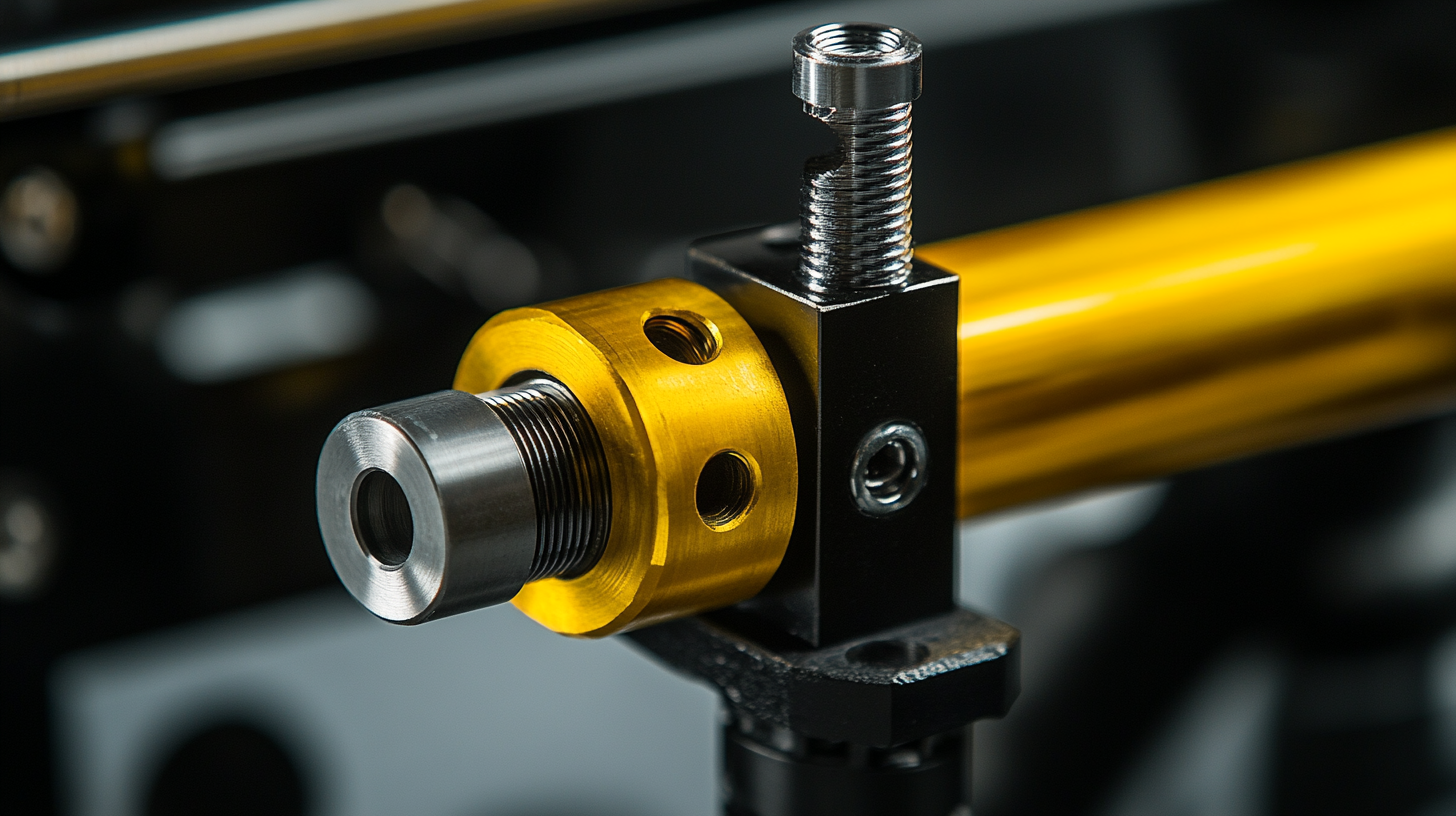

When selecting a mini hydraulic cylinder for your projects, there are key features that can make a significant difference in performance and longevity. First and foremost, consider the cylinder's material. High-quality materials, such as steel or aluminum, provide strength and resistance to corrosion, which is crucial for durability. Look for cylinders with a hard chrome-plated rod, as this enhances wear resistance and reduces the likelihood of leaks.

Additionally, pay attention to the cylinder's stroke length and bore size, as these specifications directly affect the cylinder's force output and suitability for your application. A well-chosen stroke length ensures the cylinder can accommodate your project needs while maximizing efficiency. Opt for a hydraulic cylinder with adjustable end-of-stroke options to add versatility to your setup.

Tips: Always verify compatibility with your hydraulic system to prevent potential failures. Conducting regular maintenance checks can significantly extend the life of your hydraulic cylinder, ensuring it performs optimally. Lastly, consider your project's operational environment; selecting a cylinder designed for specific conditions, such as temperature or moisture levels, will enhance reliability.

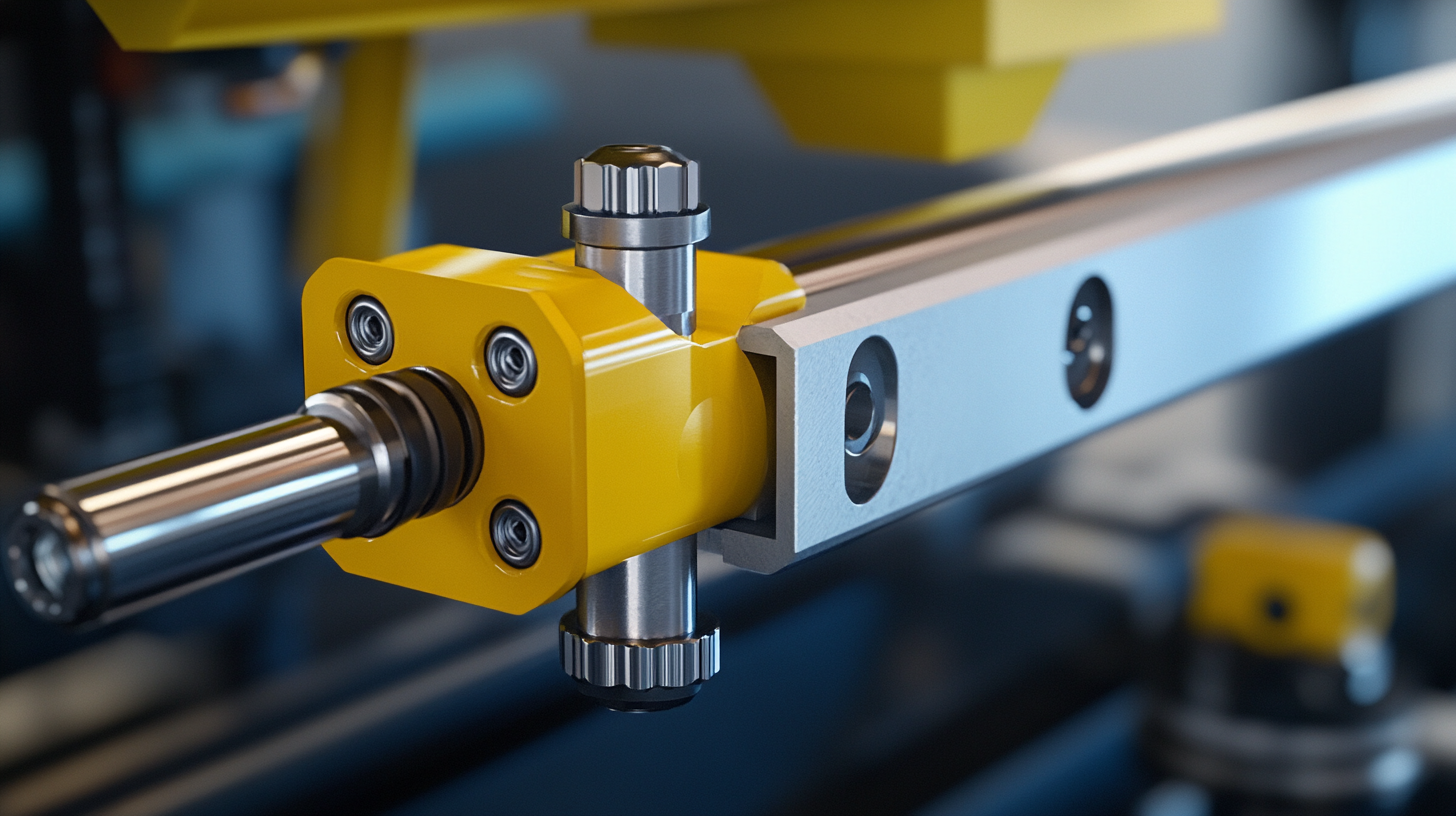

Essential Tools and Equipment for Installing Mini Hydraulic Cylinders

When it comes to installing mini hydraulic cylinders, having the right tools and equipment is crucial for ensuring a smooth and efficient process. Begin with a good hydraulic pump that matches the specifications of your cylinder. A portable hydraulic pump can enhance mobility and convenience, especially for onsite projects. Additionally, ensure that you have high-quality hoses and fittings, as these components play a vital role in maintaining pressure and preventing leaks. Selecting durable and compatible accessories not only guarantees safety but also optimizes the performance of the hydraulic system.

Moreover, consider investing in appropriate mounting brackets and supports for your mini hydraulic cylinders. These components are essential for securely fastening the cylinders in place, delivering the stability needed during operation.

Having the right wrenches and socket sets on hand will facilitate easy assembly and adjustments. Finally, safety gear, such as gloves and goggles, should not be overlooked. Working with hydraulic systems can pose risks, and personal protective equipment is vital to safeguard yourself while tackling your projects. By equipping yourself with these essential tools and equipment, you set the stage for successfully mastering the installation of mini hydraulic cylinders.

Safety Precautions When Using Mini Hydraulic Cylinders

When using mini hydraulic cylinders in your projects, safety precautions are paramount to ensure both worker well-being and equipment reliability. According to a report by the International Hydraulic Association, improper handling of hydraulic systems accounts for approximately 30% of all workplace accidents in manufacturing settings. Therefore, understanding the specific safety measures associated with mini hydraulic cylinders is essential.

First, always inspect the hydraulic system before use. A comprehensive study from the Hydraulic Systems Safety Council revealed that nearly 60% of hydraulic failures can be traced back to insufficient maintenance and lack of preventive checks. Ensure all hoses, fittings, and the cylinder itself are free from leaks or damage. Additionally, operators should be trained to recognize the signs of hydraulic fluid leaks, which can lead to not only operational inefficiencies but also hazardous workplace conditions.

Furthermore, it is crucial to follow the manufacturer's guidelines regarding the pressure capacity of mini hydraulic cylinders. Operating beyond the recommended pressure can lead to catastrophic failures. The National Institute for Occupational Safety and Health (NIOSH) states that adhering to manufacturer specifications reduces the risk of lift-related injuries by 50%. By prioritizing safety precautions, you can harness the full potential of mini hydraulic cylinders while minimizing risks associated with their operation.

Common Applications and Use Cases for Mini Hydraulic Cylinders

Mini hydraulic cylinders are increasingly gaining traction across various industries due to their versatility and efficiency. Common applications include automation, robotics, and mobile equipment, where compact design combined with powerful performance is crucial. According to industry reports, the demand for mini hydraulic cylinders is expected to rise, driven by their ability to provide significant force within limited space, making them ideal for applications where every inch counts.

Mini hydraulic cylinders are increasingly gaining traction across various industries due to their versatility and efficiency. Common applications include automation, robotics, and mobile equipment, where compact design combined with powerful performance is crucial. According to industry reports, the demand for mini hydraulic cylinders is expected to rise, driven by their ability to provide significant force within limited space, making them ideal for applications where every inch counts.

In robotics, mini hydraulic cylinders are often favored for their precise movement capabilities and ability to generate substantial force while maintaining lightweight configurations. The integration of pneumatic systems in robotics continues to show robust growth, with market analyses indicating a compound annual growth rate (CAGR) of around 6% over the next five years. These cylinders play a vital role in enhancing operational efficiency, particularly in environments where rapid and accurate actuation is essential.

Furthermore, mini hydraulic cylinders are also utilized in low-pressure water hydraulic systems, offering a reliable alternative to traditional hydraulic solutions. These systems are designed to be more cost-effective while delivering similar performance levels. Recent evaluations suggest that low-pressure water hydraulics can reduce operational costs by up to 30%, which highlights their potential for widespread adoption across various sectors including manufacturing and construction. As industries continue to evolve, the role of mini hydraulic cylinders is poised to expand significantly.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.