International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

Unlocking Efficiency with Mini Hydraulic Cylinders Benefits for Global Buyers

In today's rapidly evolving industrial landscape, the demand for enhanced efficiency and precision has led to a growing interest in specialized components like the Mini Hydraulic Cylinder. According to a recent report from the International Fluid Power Society, the global market for hydraulic cylinders is projected to reach $10 billion by 2025, driven by industries seeking compact solutions that maximize space without compromising performance. Mini hydraulic cylinders, known for their reduced size and weight, offer significant advantages in applications ranging from robotics to automotive sectors. These cylinders not only improve operational efficiency but also contribute to energy savings, proving essential for global buyers aiming to streamline their processes while adhering to sustainability goals. As industries continue to prioritize innovation and efficiency, the role of mini hydraulic cylinders becomes increasingly critical, unlocking new potential across various engineering fields.

Benefits of Mini Hydraulic Cylinders: A Global Market Overview

Mini hydraulic cylinders are becoming an essential component in various industries due to their compact size and exceptional efficiency. As global buyers increasingly seek ways to optimize their operations, the demand for these cylinders has surged. The global hydraulic cylinder market, valued at approximately USD 14.3 billion in 2021, is expected to grow to USD 18.3 billion by 2027, highlighting the rising trend in compact hydraulic solutions.

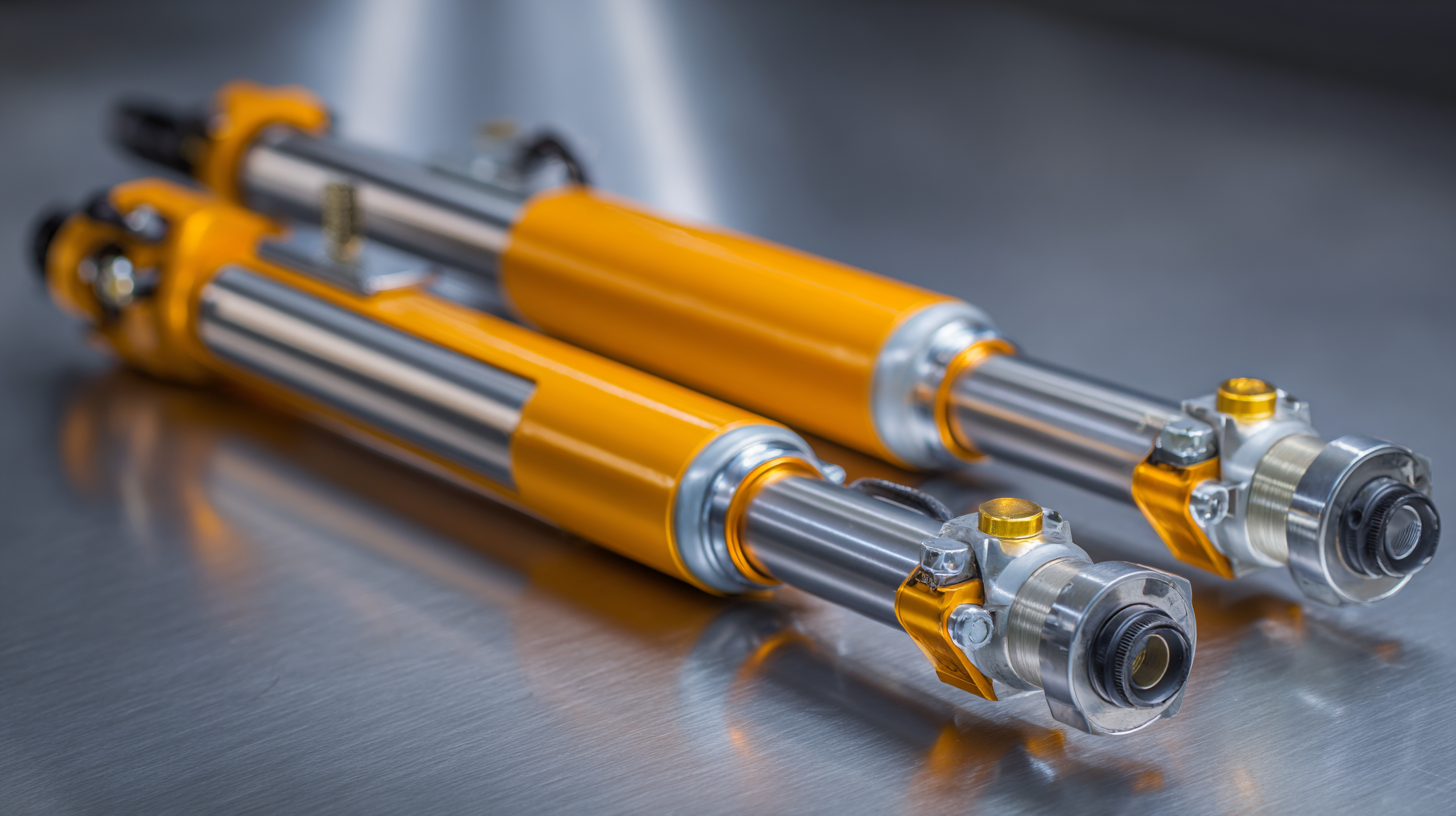

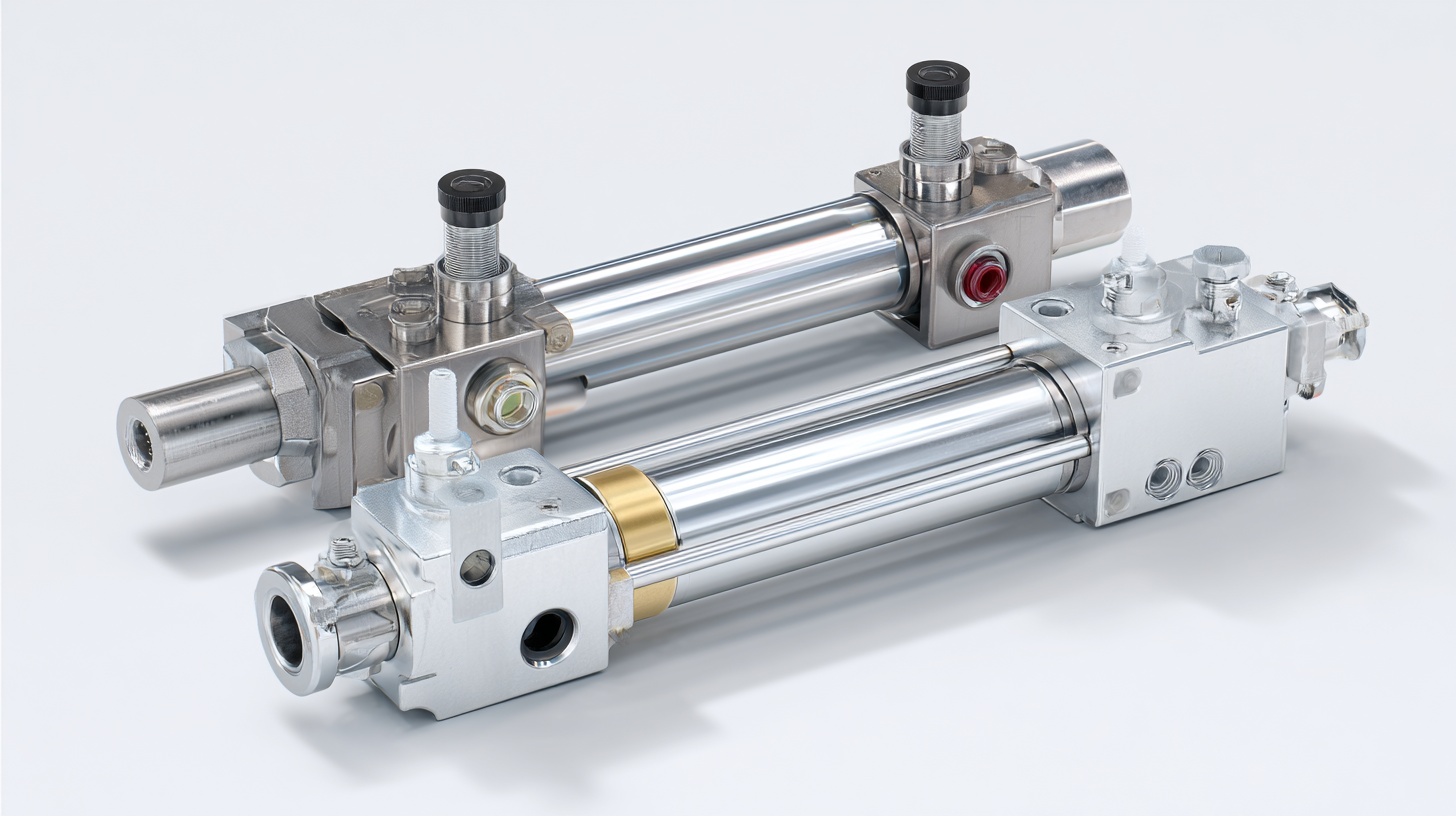

One of the primary benefits of mini hydraulic cylinders lies in their ability to provide significant force while occupying minimal space. This makes them particularly advantageous for industries such as construction and manufacturing, where space constraints are a common challenge. Additionally, their lightweight design contributes to improved maneuverability, allowing for greater flexibility in various applications.

Tips for Buyers: When considering mini hydraulic cylinders, pay attention to the specifications that meet your specific needs. Look for manufacturers that offer customization options to ensure optimal performance in your application. Additionally, evaluate the durability and maintenance requirements of the cylinders to ensure long-term reliability. Exploring these factors can help maximize the efficiency and effectiveness of your hydraulic systems in the global market.

Understanding the Efficiency Gains of Mini Hydraulic Cylinders in Industrial Applications

In today’s fast-paced industrial landscape, mini hydraulic cylinders are emerging as a game-changer for efficiency in a variety of applications. These compact solutions provide substantial power while occupying minimal space, making them ideal for environments where traditional hydraulic systems might be impractical. The ability to control force and movement precisely not only enhances productivity but also reduces energy consumption, leading to significant cost savings over time.

When integrating mini hydraulic cylinders into your operations, consider these tips for maximizing their efficiency. First, assess the specific load requirements of your application to select the appropriate cylinder size and force output. Oversizing can lead to wasted energy and inefficient operation. Secondly, maintain regular inspections and maintenance of your hydraulic systems to prevent leaks and performance drops. A well-maintained cylinder operates smoothly, ensuring that you reap the full benefits of its design.

Lastly, training your operators on the correct handling and applications of mini hydraulic cylinders can lead to increased safety and enhanced productivity. Understanding the operational limits and capabilities of these cylinders allows workers to utilize them effectively, ensuring that your investment pays off in both performance and longevity. Embrace these strategies to unlock the full potential of mini hydraulic cylinders in your operations.

Key Metrics: The Impact of Mini Hydraulic Cylinders on Operational Costs and Productivity

Mini hydraulic cylinders have emerged as a vital component for businesses seeking to enhance operational efficiency. Their compact design and high performance can significantly reduce operational costs while boosting productivity. By integrating these cylinders into existing machinery, companies can achieve more precise control over their hydraulic systems, leading to more efficient energy use and reduced waste. This allows for smoother operations and can lower the total cost of ownership for hydraulic equipment.

From a productivity standpoint, mini hydraulic cylinders facilitate faster cycle times and improved output quality. Their responsiveness enables machinery to perform tasks more swiftly, thereby increasing throughput. Additionally, the reduction in size and weight of these cylinders can lead to lighter equipment, contributing to a more agile manufacturing process. Global buyers looking to optimize their operations should consider the impressive metrics associated with the implementation of mini hydraulic cylinders, as these benefits can translate directly into increased competitiveness in a demanding marketplace.

Unlocking Efficiency with Mini Hydraulic Cylinders Benefits for Global Buyers

| Metric | Value | Impact on Operational Costs (%) | Impact on Productivity (%) |

|---|---|---|---|

| Average Cylinder Weight | 15 kg | -10% | +15% |

| Typical Life Span | 5 years | -15% | +10% |

| Fluid Consumption Reduction | 20% | -20% | +25% |

| High Efficiency Rating | 98% | -5% | +20% |

| Operating Temperature Range | -20°C to 80°C | n/a | n/a |

Comparative Analysis: Mini Hydraulic Cylinders Versus Traditional Hydraulic Solutions

Mini hydraulic cylinders have emerged as a formidable alternative to traditional hydraulic solutions, offering distinct advantages that enhance efficiency and performance for global buyers. When comparing these two options, one of the most significant benefits of mini hydraulic cylinders is their compact size. This design allows for easier installation in tight spaces while still delivering impressive power and performance. Moreover, the reduced weight of mini hydraulic cylinders can lead to lighter machinery and lower energy consumption, making them an appealing choice for industries aiming to optimize operational efficiency.

**Tips:** When considering a switch to mini hydraulic cylinders, focus on the specific requirements of your application. Assess the available installation space and the power needed for your tasks to ensure compatibility. Additionally, it can be beneficial to consult with manufacturers about customization options that align with your operational demands.

Another notable aspect is the cost-effectiveness of mini hydraulic cylinders. While traditional hydraulic systems often come with higher maintenance costs due to their complexity, mini cylinders typically require less upkeep, resulting in lower long-term expenditures. This financial efficiency is particularly attractive to global buyers working with tight budgets.

**Tips:** Always compare the total cost of ownership for both mini hydraulic and traditional hydraulic solutions. Be mindful of not just initial investments but also long-term maintenance and operational costs. Investing time in analyzing these factors can lead to better decision-making and potentially significant savings.

Unlocking Efficiency with Mini Hydraulic Cylinders

This chart compares the performance of mini hydraulic cylinders and traditional hydraulic solutions across several key dimensions:

Future Trends: Innovations in Mini Hydraulic Cylinder Technology and Market Growth Projections

The mini hydraulic cylinder market is poised for significant growth, driven by innovations in technology and increasing demand across various sectors. In 2018, the global hydraulic cylinder market was valued at $10.94 billion, and projections indicate a rise to $19.77 billion by 2032, fueled by a compound annual growth rate of 4% during the forecast period. This upward trend highlights the growing preference for compact and efficient solutions that mini hydraulic cylinders offer.

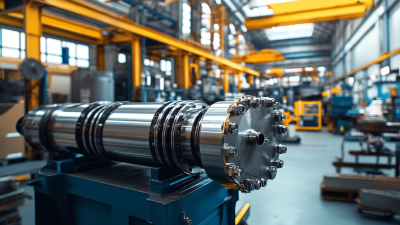

Future trends in mini hydraulic cylinder technology include advancements in materials and design that enhance performance while reducing weight and size. With industries seeking more efficient alternatives for power transmission and control, manufacturers are exploring innovative designs that allow for better integration into modern machinery. Additionally, the evolution of smart technologies, such as IoT-enabled systems, is beginning to influence the functionality of hydraulic systems, making them more adaptable and responsive to user needs. As sustainability becomes a focal point, the development of eco-friendly materials and energy-efficient designs is expected to play a crucial role in shaping the market dynamics for mini hydraulic cylinders in the years to come.

Related Posts

-

Innovative Strategies for Sourcing Hyd Cylinders Worldwide

-

Understanding the Benefits of Hydraulic Power Packs for Your Business

-

What Are the Key Benefits of Using Hydraulic Cylinder Tools in Modern Manufacturing

-

Evaluating the Performance Metrics of Used Hydraulic Cylinders in Heavy Machinery Applications

-

2025 Trends in Compact Hydraulic Cylinders: Innovative Strategies for Industry Leaders

-

Benefits of Choosing the Best Hydraulic Power Pack for Your Business Needs

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.