International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

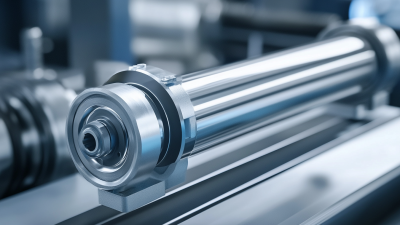

How to Optimize the Performance of Compact Hydraulic Cylinders for Your Projects

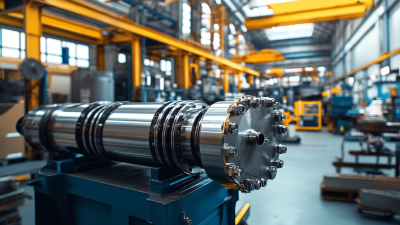

In recent years, the demand for Compact Hydraulic Cylinders has surged across various industries, driven by the need for efficient, space-saving solutions in applications ranging from automotive manufacturing to robotics. According to a report by Research and Markets, the global hydraulic cylinder market is expected to reach $17.4 billion by 2026, with a significant portion attributed to compact designs that maximize output while minimizing footprint.

These hydraulic cylinders are essential in achieving high performance in confined spaces where traditional systems may falter. Optimizing the performance of Compact Hydraulic Cylinders involves understanding the intricacies of their design, materials, and operational parameters, thus ensuring that projects not only meet stringent performance standards but also enhance operational efficiency in increasingly competitive environments.

These hydraulic cylinders are essential in achieving high performance in confined spaces where traditional systems may falter. Optimizing the performance of Compact Hydraulic Cylinders involves understanding the intricacies of their design, materials, and operational parameters, thus ensuring that projects not only meet stringent performance standards but also enhance operational efficiency in increasingly competitive environments.

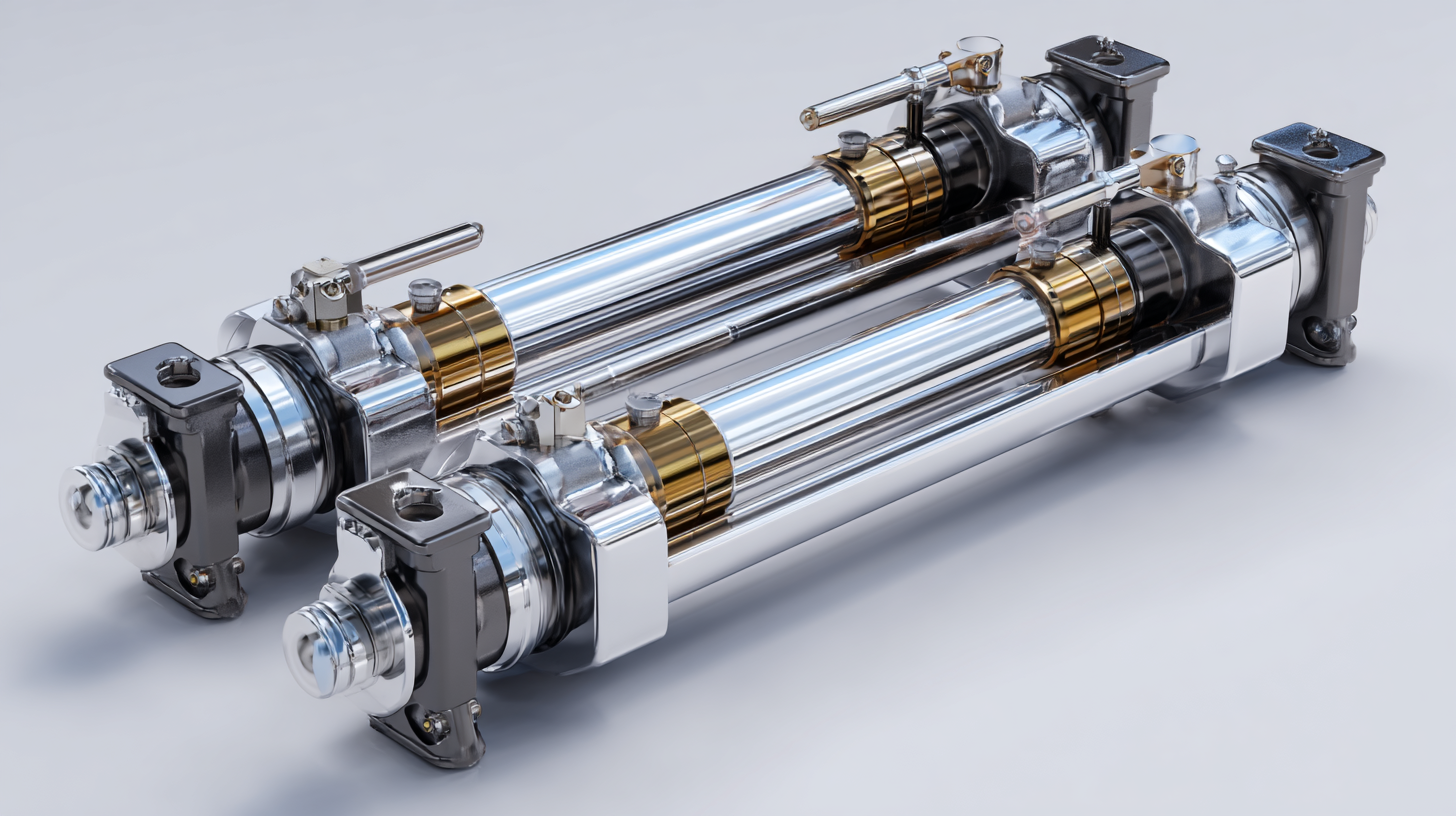

Understanding the Basics of Compact Hydraulic Cylinder Design

Compact hydraulic cylinders are essential components in various applications, providing reliable performance in limited spaces. To optimize the design of these cylinders, it is crucial to understand the basic principles governing their construction. The design typically involves a combination of features, including bore diameter, stroke length, and the type of material used for the cylinder body. These factors directly influence the cylinder's efficiency, strength, and response time.

Compact hydraulic cylinders are essential components in various applications, providing reliable performance in limited spaces. To optimize the design of these cylinders, it is crucial to understand the basic principles governing their construction. The design typically involves a combination of features, including bore diameter, stroke length, and the type of material used for the cylinder body. These factors directly influence the cylinder's efficiency, strength, and response time.

Another important aspect of compact hydraulic cylinder design is the careful selection of seals and fittings. High-quality seals minimize leakage and ensure a longer operational life, while appropriately sized fittings facilitate smooth fluid flow and pressure management. Additionally, considering the type of hydraulic fluid used can enhance performance, as different fluids exhibit varying properties that affect lubrication and cooling. By focusing on these fundamental design aspects, engineers can significantly improve the performance and durability of compact hydraulic cylinders, making them more effective for demanding project requirements.

Key Factors Influencing the Performance of Hydraulic Cylinders

When optimizing the performance of compact hydraulic cylinders, several key factors play a critical role. First, the design and materials used in the cylinder construction significantly impact its efficiency and durability. High-quality materials, such as hardened steel or advanced composites, provide better resistance to wear and tear, allowing for smoother operation and reduced maintenance needs. Additionally, precise engineering ensures proper alignment and minimizes friction, which directly affects the cylinder's responsiveness and longevity.

Another crucial factor is the hydraulic fluid utilized within the system. The choice of fluid not only influences the performance of the hydraulic circuit but also affects temperature management and overall efficiency. Proper fluid selection, complemented by regular monitoring of viscosity and contamination levels, is essential for maintaining optimal performance. Moreover, the implementation of advanced control systems can enhance the responsiveness of the cylinders, allowing for greater precision in operations and improved energy efficiency. By focusing on these critical influences, projects can achieve superior performance from compact hydraulic cylinders.

Optimization of Compact Hydraulic Cylinder Performance

This chart illustrates the key factors influencing the performance of compact hydraulic cylinders based on several parameters such as pressure, temperature, and load capacity.

Techniques for Enhancing Hydraulic Cylinder Efficiency

Optimizing the performance of compact hydraulic cylinders is essential for enhancing the efficiency of various industrial applications. One key technique involves implementing advanced sealing solutions. According to a report from the International Fluid Power Exposition, well-designed seals can reduce fluid leakage by up to 50%, significantly improving energy efficiency and extending the cylinder's lifespan. Choosing the right sealing materials and designs tailored for specific operating conditions can further enhance performance under varying temperatures and pressures.

Another effective approach is to select the appropriate hydraulic fluid. The Hydraulic Pump and Motor Association states that using fluids with superior lubrication properties can increase hydraulic efficiency by 20% or more. It’s crucial to analyze the fluid’s viscosity and ensure it aligns with the cylinder's operating conditions. Regular fluid analysis and timely replacement are essential to maintain optimal performance throughout the hydraulic system.

Tips: Regular maintenance schedules should be established to inspect cylinders for wear and tear, ensuring that any issues are addressed promptly. Additionally, adjusting rod diameters and incorporating lightweight materials in design can improve responsiveness and reduce energy consumption. Ultimately, both predictive maintenance and thoughtful design choices enhance the overall efficiency of hydraulic systems in various applications.

Maintenance Practices for Long-lasting Hydraulic Cylinder Performance

To ensure the long-lasting performance of compact hydraulic cylinders, maintenance practices are crucial. Regularly inspecting the cylinders for signs of wear and contaminants can prevent potential failures. One effective method is the implementation of magnetic filtration technology, which captures debris and small contaminants in hydraulic fluid. By using this pre-filter solution, you can significantly extend the life of hydraulic systems and ensure consistent performance.

- Regular Oil Changes: Adhere to the manufacturer’s recommended oil drain intervals to maintain optimal performance. Changing the oil at prescribed intervals helps remove contaminants that could impair cylinder function.

- Monitor Performance with Sensors: Integrating sensors into your hydraulic systems facilitates predictive maintenance. This allows you to track condition data and anticipate issues before they become critical, effectively minimizing downtime.

- Inspect Seals and Connections: Regularly check all seals and connections for leaks and signs of wear. A small leak can lead to significant performance issues if not addressed promptly, so proactive inspections are key to maintaining hydraulic efficiency.

Troubleshooting Common Issues in Compact Hydraulic Cylinders

Compact hydraulic cylinders are widely used in various applications due to their efficient performance in limited spaces. However, they may encounter common issues that can hinder their functionality. One prevalent problem is leakage, which can result from worn seals or improper assembly. To troubleshoot this, it's essential to regularly inspect the cylinder's seals and replace them as needed. Tightening any loose connections can also help reduce the risk of leaks, ensuring optimal operation.

Another common issue is overheating, which can cause significant wear and reduce the lifespan of the cylinder. Overheating may be due to excessive load, inadequate fluid levels, or poor ventilation. To address this, operators should verify that the hydraulic systems are correctly calibrated, ensuring the load is within design specifications. Additionally, maintaining proper fluid levels and ensuring proper airflow around the cylinder can help mitigate overheating. Regular maintenance schedules and performance checks can proactively identify and remedy these common issues, ultimately enhancing the reliability and efficiency of compact hydraulic cylinders in various projects.

How to Optimize the Performance of Compact Hydraulic Cylinders for Your Projects - Troubleshooting Common Issues in Compact Hydraulic Cylinders

| Issue | Possible Causes | Solutions | Prevention |

|---|---|---|---|

| Cylinders not extending/retracting | Low pressure, blocked ports | Check fluid levels, clear obstructions | Regular maintenance checks |

| Oil leakage | Worn seals, damaged cylinder | Replace seals, inspect cylinder | Use quality seals and components |

| Slow operation | Viscosity issues, clogged filters | Change hydraulic fluid, replace filters | Monitor fluid status and filter changes regularly |

| Noise during operation | Air in system, inadequate lubrication | Bleed the system, ensure proper lubrication | Perform air bleeding after maintenance |

| Overheating | Over-pressure, inadequate cooling | Reduce load, improve cooling system | Regularly check system pressure |

Related Posts

-

Hydraulic Cylinder Tools Trends Shaping the Future of Global Procurement in 2025

-

Innovative Applications of Stainless Steel Hydraulic Cylinders in Modern Machinery

-

Innovative Strategies for Sourcing Hyd Cylinders Worldwide

-

Unlocking Global Supply Chain Efficiency with Our Unique Hydraulic Cylinder Catalogue Insights

-

Unleashing Global Potential Small Hydraulic Cylinders from Chinas Leading Manufacturer

-

Exploring the Characteristics and Applications of Best Replacement Hydraulic Cylinders for Global Buyers

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.