International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

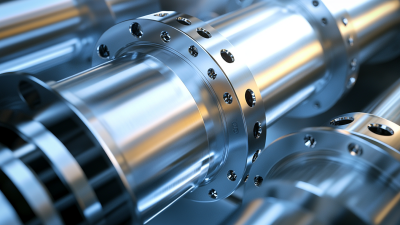

Solutions for Optimizing Performance with Stainless Steel Hydraulic Cylinders

In the realm of hydraulic machinery, the performance and durability of components play a crucial role in operational efficiency. Stainless Steel Hydraulic Cylinders have emerged as pivotal elements in various industrial applications, offering enhanced resistance to corrosion and wear, which are critical in harsh environments. According to a recent report by the International Hydraulics Association, the use of stainless steel in hydraulic components can increase lifespan by 30% compared to traditional materials, ultimately leading to reduced maintenance costs and improved reliability. As industries strive for optimal performance and sustainability, understanding the best practices for utilizing Stainless Steel Hydraulic Cylinders becomes essential. This guide aims to explore innovative solutions for maximizing the efficiency and longevity of these vital components, ensuring consistent performance in demanding applications.

Best Practices for Material Selection in Stainless Steel Hydraulic Cylinders

When it comes to hydraulic cylinders, the choice of materials significantly affects performance and longevity. Stainless steel is often favored due to its excellent corrosion resistance, strength, and durability. However, selecting the right grade of stainless steel is crucial for optimal performance. For high-pressure applications, austenitic stainless steels like 304 and 316 offer exceptional mechanical properties and resistance against pitting, making them ideal for environments exposed to corrosive elements.

In addition to choosing the correct stainless steel grade, considerations such as machining capabilities, welding characteristics, and surface finish should not be overlooked. Proper surface treatment can enhance the wear resistance of the cylinder and reduce friction, which is essential for smooth operation. Incorporating practices such as passivation can further improve corrosion resistance, ensuring the hydraulic cylinders maintain peak performance even in harsh conditions. Ultimately, informed material selection coupled with best manufacturing practices will lead to hydraulic cylinders that excel in functionality and durability.

Performance Optimization of Stainless Steel Hydraulic Cylinders

This bar chart illustrates the key performance metrics for optimizing stainless steel hydraulic cylinders. The metrics include corrosion resistance, pressure resistance, weight, cost, and durability, with values ranging from 60 to 95, representing the effectiveness of material selection in enhancing cylinder performance.

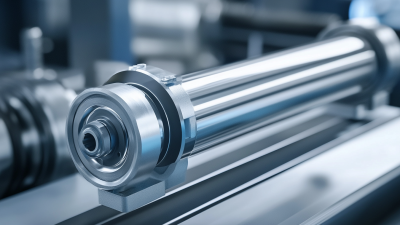

Understanding Corrosion Resistance and Its Impact on Performance

Corrosion resistance is a critical factor affecting the performance and longevity of stainless steel hydraulic cylinders. Hydraulic systems are often exposed to harsh environments, where moisture, chemicals, and extreme temperatures are prevalent. Choosing the right stainless steel alloy can significantly enhance resistance to corrosion, ensuring that the hydraulic cylinders operate efficiently over time. Alloys such as 316 stainless steel, which contains molybdenum, offer superior protection against pitting and crevice corrosion, making them ideal for use in marine applications and other corrosive settings.

In addition to selecting appropriate materials, implementing effective maintenance strategies also plays a vital role in optimizing performance. Regular inspections and prompt maintenance can prevent the onset of corrosion, which, if left unchecked, could lead to cylinder failure and costly repairs. Coatings and surface treatments can further enhance corrosion resistance, providing an additional layer of protection. Understanding the interactions between different environmental factors and the materials used in hydraulic cylinders is essential for maximizing their efficiency and lifespan in various applications.

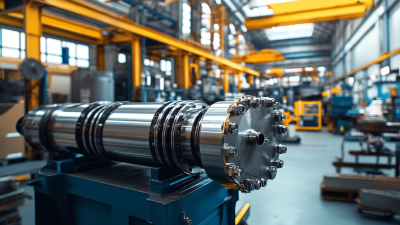

Optimizing Cylinder Design for Enhanced Efficiency and Strength

Optimizing the design of stainless steel hydraulic cylinders is crucial for improving both efficiency and strength. By harnessing advanced engineering techniques, manufacturers can create cylinders that minimize resistance and enhance fluid dynamics. The use of computational fluid dynamics (CFD) during the design phase allows for precise simulations of fluid flow, enabling engineers to identify optimal shapes and sizes that improve performance. Moreover, incorporating features such as tapered ends or smooth transitions can significantly reduce turbulence, leading to a more efficient operation.

In addition to enhancing efficiency, the structural integrity of hydraulic cylinders is paramount. Selecting the right grade of stainless steel can increase resistance to corrosion and fatigue, prolonging the life cycle of the cylinder. Designers should also consider wall thickness and reinforcement patterns to balance weight and durability. Implementing innovations such as stress analysis software enables engineers to anticipate points of failure, ensuring that the cylinders can withstand high pressures and loads without compromising performance. By focusing on these aspects in the design phase, manufacturers can produce hydraulic cylinders that are not only efficient but also robust enough to meet demanding applications.

Role of Sealing Solutions in Performance Optimization of Hydraulic Cylinders

In modern hydraulic systems, the role of sealing solutions is crucial for optimizing the performance of stainless steel hydraulic cylinders. As hydraulic actuators are fundamental components in various engineering applications, including aerospace and heavy machinery, the integrity of their sealing mechanisms directly impacts overall efficiency and reliability. Recent studies highlight the significance of managing friction within these sealing systems, emphasizing that lower friction can lead to enhanced operational performance and longevity of the hydraulic cylinders.

One innovative approach involves the development of multi-lip reciprocating seals that enhance the sealing capabilities while minimizing wear and tear. Research shows that these advanced seal designs can significantly improve energy efficiency in hydraulic systems, thereby reducing operational costs. Additionally, the incorporation of new materials and designs, such as a unique rubber ring structure, demonstrates promising results in terms of sealing performance compared to traditional designs.

These advancements not only address the challenges of hydraulic cylinder operation but also cater to the increasing demands for reliability and efficiency in industrial applications.

Conducting Regular Maintenance: A Key to Longevity and Performance

Regular maintenance of stainless steel hydraulic cylinders is crucial for ensuring their longevity and optimal performance in various applications. These cylinders, known for their durability and corrosion resistance, can significantly benefit from routine inspections and upkeep. By systematically checking for wear and tear, leaks, and optimal fluid levels, operators can preemptively address issues that may compromise the cylinder’s functionality.

In addition to routine inspections, lubricating moving parts and replacing seals when necessary plays a vital role in maintaining the performance of hydraulic cylinders. Regular maintenance not only extends the lifespan of the equipment but also enhances efficiency, reducing the risk of unexpected breakdowns. Implementing a preventive maintenance schedule tailored to the specific conditions and usage patterns of the cylinders can lead to substantial cost savings and increased operational reliability in the long run.

Related Posts

-

Innovative Applications of Stainless Steel Hydraulic Cylinders in Modern Machinery

-

Innovative Strategies for Sourcing Hyd Cylinders Worldwide

-

Unlocking Global Supply Chain Efficiency with Our Unique Hydraulic Cylinder Catalogue Insights

-

Unleashing Global Potential Small Hydraulic Cylinders from Chinas Leading Manufacturer

-

Exploring the Characteristics and Applications of Best Replacement Hydraulic Cylinders for Global Buyers

-

Proudly Crafting World Class Small Hydraulic Cylinders in China for Global Excellence

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.