International Fluid Power Inc.

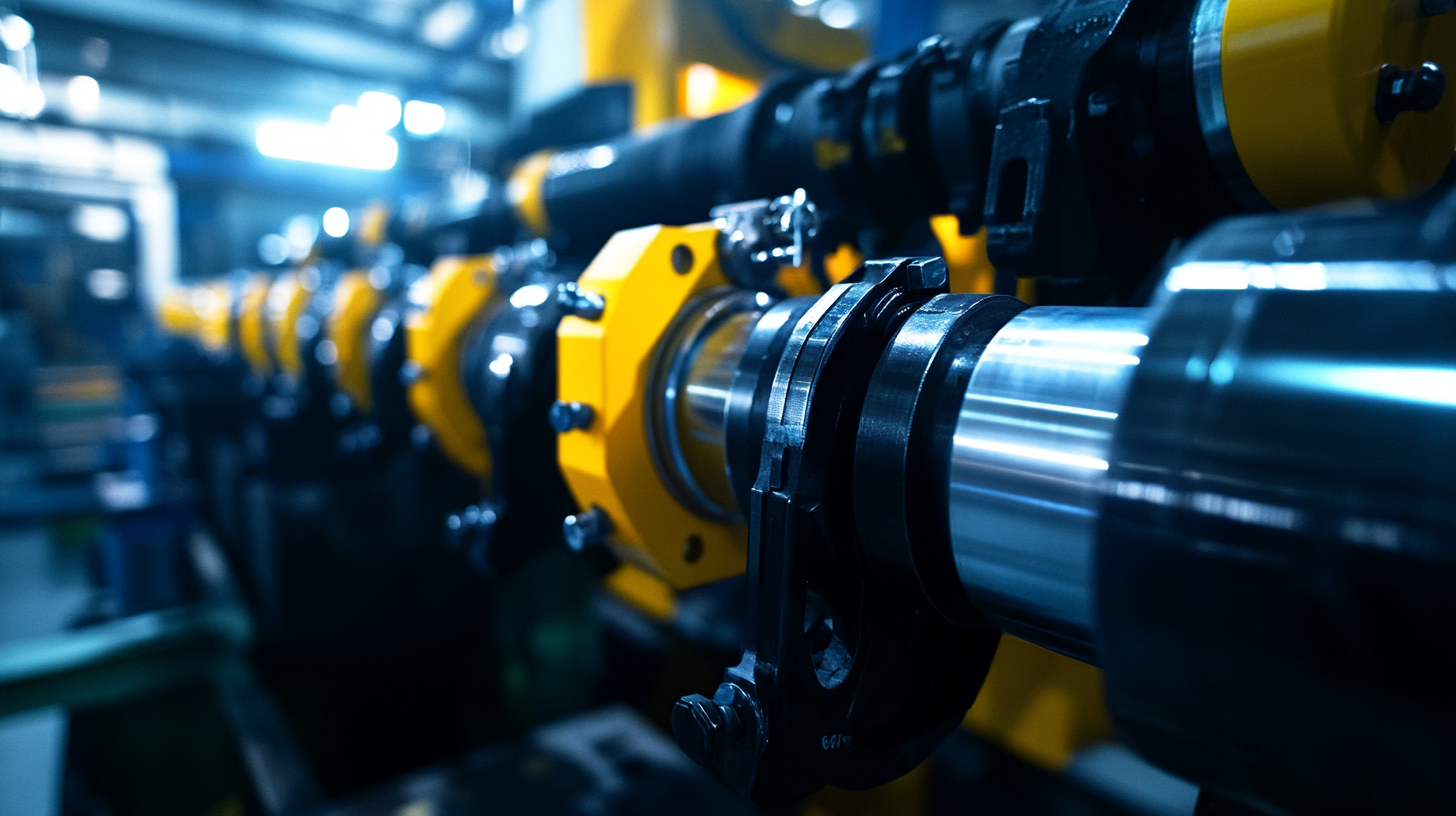

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

Resilient Growth of Chinese Manufacturers Amidst US China Tariff War with Focus on Best Compact Hydraulic Cylinder

In the face of escalating tariffs and trade tensions between the United States and China, the resilience of Chinese manufacturers stands out, particularly in sectors heavily influenced by the global supply chain. According to a report by the China Hydraulic and Pneumatic Association, the hydraulic equipment market is expected to surpass $27 billion by 2025, with compact hydraulic cylinders playing a crucial role in this growth. These components are essential in various applications, ranging from construction machinery to agricultural equipment, driving demand and innovation despite external economic pressures. As Chinese manufacturers adapt strategically, they not only navigate the challenges posed by tariffs but also leverage their capabilities to excel in the production of compact hydraulic cylinders. This trend reflects a broader narrative of resilience and adaptability in the Chinese manufacturing landscape amidst a backdrop of significant geopolitical shifts.

Chinese Manufacturers: Adapting Strategies for Tariff Challenges

Chinese manufacturers have been navigating the turbulent waters of the US-China tariff war with remarkable resilience, employing strategic adaptations to maintain their competitive edge. According to a report from the China National Bureau of Statistics, manufacturing output growth in China reached 6.2% in 2022, showing that many firms are not only surviving but thriving despite increased tariffs. One notable sector is hydraulic cylinders, which are integral to various applications, from automotive to construction. The demand for compact hydraulic cylinders has surged, fueled by innovations in technology and rising domestic and international construction projects.

To counteract tariff impacts, Chinese manufacturers are shifting their strategies. A survey conducted by the China Council for the Promotion of International Trade found that over 60% of companies have diversified their supply chains and sourcing strategies to mitigate risks. This includes investing in automation and efficient production processes to reduce costs and improve quality. Companies are also focusing on the export of high-value products, such as advanced compact hydraulic cylinders, which not only bypass some tariff implications but also position these manufacturers as leaders in the global market. This strategic pivot illustrates how Chinese manufacturers are not merely reacting to challenges but are strategically positioning themselves for future growth.

Impact of Tariffs on Supply Chains: Navigating the New Landscape

The evolving tariff landscape under the current U.S. administration has profoundly impacted supply chains across various sectors, particularly for manufacturers operating in the hydraulic cylinder industry. As companies assess the implications of tariffs on metals and manufactured goods — which have significantly increased costs — strategic adjustments are essential. A recent report highlighted that nearly 70% of manufacturers are considering sourcing alternatives to navigate the current turbulence, indicating a substantial shift in procurement strategies.

Furthermore, supply chain disruptions linked to tariffs have prompted businesses to reassess their logistics and supplier networks. A survey found that 60% of shippers are exploring partnerships with third-party logistics providers to mitigate the complexities introduced by tariff changes. This move not only aims to reduce costs but also to enhance efficiency amidst a climate of uncertainty. As firms in the compact hydraulic cylinder market adapt, their resilience will be tested against these external pressures, which could redefine competitive dynamics and influence future operational frameworks.

Innovations in Compact Hydraulic Cylinder Production

The compact hydraulic cylinder industry has witnessed remarkable innovations, particularly among Chinese manufacturers navigating the complexities of the US-China tariff war. According to a report by ResearchAndMarkets, the global market for hydraulic cylinders is projected to reach approximately $16 billion by 2026, with compact hydraulic cylinders making significant contributions due to their versatility and efficiency. These advancements are spurred by ongoing investments in research and development, allowing manufacturers to produce lighter, more durable, and energy-efficient models that meet stringent engineering demands.

Chinese manufacturers are increasingly leveraging advanced technologies such as IoT and smart manufacturing processes to enhance productivity and product quality. For instance, a study by MarketsandMarkets highlights that the adoption of IoT-enabled hydraulic systems can reduce maintenance costs by up to 30%. Companies are also focusing on eco-friendly production techniques to comply with global environmental standards, which is crucial for competing in international markets. As a result, the resilience of Chinese manufacturers in this sector reflects their ability to innovate swiftly while adapting to external economic pressures, ensuring sustained growth despite global trade challenges.

Export Trends: Resilient Markets Amidst Tariff Pressures

The ongoing US-China tariff war has significantly reshaped the landscape for manufacturers, particularly in sectors reliant on exports. Reports indicate that, despite rising tariff pressures, global trade reached an impressive $33 trillion in 2024, marking a 3.7% increase from the previous year. This growth has been largely fueled by the resilience of developing economies, including those in Southeast Asia, which saw their economies grow at an average rate of 5% in Q4 of 2024 despite external uncertainties. Chinese manufacturers, facing overcapacity and pressure from tariffs, have adapted by enhancing their operational efficiencies and focusing on niche markets like compact hydraulic cylinders.

As the complexities of the global supply chain evolve, the chemical sector exemplifies the broader challenges and opportunities manufacturers face. Recent analyses highlight that US companies are diversifying their supplier bases in response to tariff-induced disruptions, seeking suppliers both domestically and in other viable markets. This pivot not only illustrates the shifting dynamics of global trade but also underscores the potential for manufacturers in resilient markets like ASEAN to capture more market share as they buffer against the adverse effects of tariff wars. The adaptability of these manufacturers will be crucial as they navigate through evolving trade policies and strive for continued growth in an unpredictable economic climate.

Success Stories: Chinese Firms Thriving in a Tariff-Heavy Environment

In the midst of the escalating US-China tariff war, numerous Chinese manufacturers have demonstrated remarkable resilience and adaptability, particularly in the compact hydraulic cylinder sector. According to industry reports, the Chinese hydraulic cylinder market was valued at approximately $3.5 billion in 2021 and is projected to witness a CAGR of 5.2% through 2026. This growth trajectory highlights the capability of Chinese firms to leverage innovation and optimize production processes despite facing harsh trade barriers.

Success stories from leading Chinese manufacturers, such as Zhongchuan and HPG, showcase how these companies have thrived by diversifying their supply chains and investing in R&D. By fostering local partnerships and prioritizing high-quality standards, these firms not only maintain competitiveness but also capture a growing share of the global market. Furthermore, data from the China Hydraulic Pneumatic Seal Industry Association illustrates a marked increase in exports, with a reported 15% rise in shipments to Southeast Asia over the past year.

**Tips for Manufacturers:**

To navigate a tariff-heavy environment, manufacturers should consider increasing automation in production processes and embracing digital transformation strategies. Additionally, exploring alternative markets and enhancing product quality can further mitigate risks associated with international trade. By focusing on these strategies, companies can not only survive but thrive in challenging economic landscapes.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.