International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

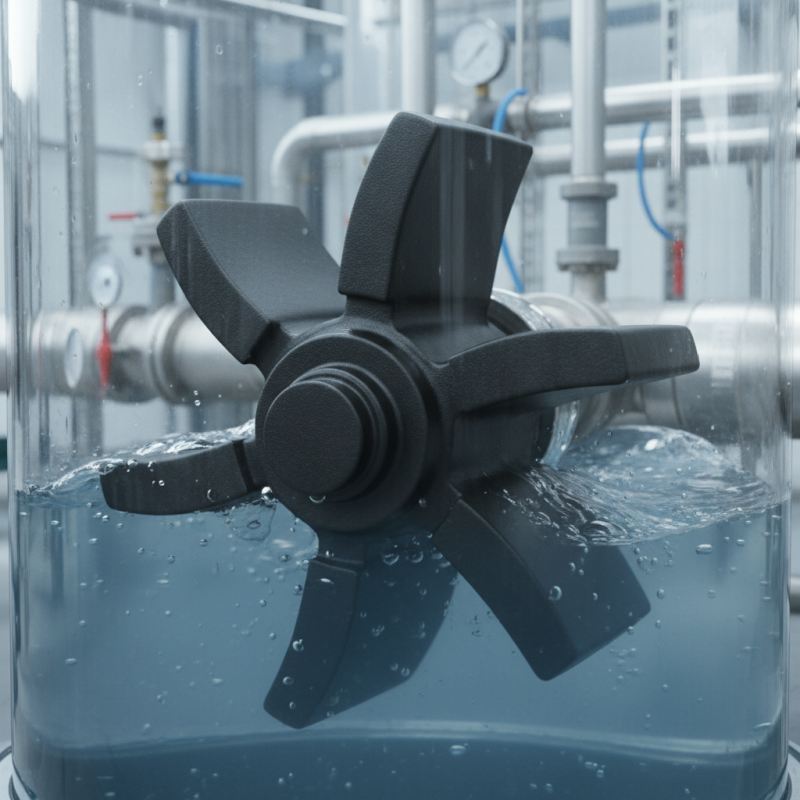

What is a Rubber Pump Impeller and How Does it Work?

Rubber Pump Impellers play a crucial role in various applications, from water treatment to industrial processes. According to a report by Grand View Research, the global pump market is expected to reach $60 billion by 2025, highlighting the demand for efficient pumping solutions. Industry expert John Smith states, "The efficiency of a pump is highly dependent on its impeller design." This emphasizes the importance of Rubber Pump Impellers in ensuring optimal performance.

These impellers are designed to handle various fluids, providing flexibility and durability. Their resistance to wear and tear makes them a preferred choice in challenging environments. However, not all rubber impellers are created equal. Some may lack the necessary properties, leading to inefficiency or failure. This presents a need for continuous improvement and innovative designs in the industry.

Understanding the mechanics behind Rubber Pump Impellers is vital for operators and engineers alike. They must evaluate the materials, shapes, and performance in real-time applications. Enhancements in technology can offer better solutions, yet the industry often grapples with balancing cost and effectiveness. Ultimately, the pursuit of perfection in rubber impeller design remains a work in progress.

What is a Rubber Pump Impeller?

A rubber pump impeller is a crucial part of many fluid systems. It helps in moving liquids efficiently through a pump. Commonly made from durable rubber materials, it provides flexibility and resilience. This allows it to handle various fluids, from water to viscous solutions. The design of an impeller is critical in determining how well it works.

When the impeller spins, it creates a vortex that draws fluid into the pump. The centrifugal force then pushes the liquid outward, generating flow. This simple mechanism plays a vital role in many industries. However, not all rubber impellers are created equal. Some may wear down faster than expected. Regular maintenance is essential to ensure optimal performance. Noticing early signs of wear can prevent bigger issues later on.

Rubber impellers also have limitations. They might not be suitable for every application. For example, abrasive fluids can cause damage over time. Understanding the specific requirements of a system is necessary. Choosing the right impeller will improve efficiency and reduce the risk of failure.

Materials Used in Rubber Impeller Construction

Rubber impellers play a crucial role in various pumping systems. They are known for their durability and flexibility. The materials used in their construction significantly affect performance. Often, manufacturers utilize synthetic rubber compounds. These compounds offer resistance to wear, abrasion, and corrosion.

Common materials include neoprene, nitrile, and EPDM. Each has unique properties. For instance, neoprene is excellent against oil and chemicals. Nitrile has better resistance to petroleum products. EPDM is favored for high-temperature applications. According to a recent industry report, over 60% of pumps utilize some form of rubber impellers, highlighting their prevalence.

The choice of material can directly influence efficiency. Improper selection may lead to faster degradation, resulting in increased downtime. Data indicates that incorrect material use can reduce a pump’s life by up to 40%. This situation requires ongoing assessment and adjustment. That said, understanding material properties is vital for optimal performance and longevity.

Rubber Pump Impeller Material Properties

The Functionality of a Rubber Pump Impeller

A rubber pump impeller plays a crucial role in fluid movement within a pump. Its primary function is to convert rotational energy from the motor into kinetic energy, resulting in fluid flow. The rubber material is essential for flexibility and resistance to wear. This makes it suitable for various applications, especially where harsh fluids are involved.

One key feature of rubber impellers is their efficiency in handling different fluid types. They can manage slurries, chemicals, and even food products. However, over time, these impellers can degrade. Regular inspection is necessary to ensure optimal performance. If you notice abnormal vibrations or reduced flow, it might be time to evaluate the impeller’s condition.

**Tips:** Using a rubber pump impeller in the right environment can extend its life. Always monitor fluid temperatures and chemical compatibility. Cleaning the impeller regularly can help prevent buildup that affects performance. Keep in mind, though, that even the best-maintained rubber impellers may eventually need replacement. Make periodic assessments part of your routine. Evaluating their performance can identify issues before they become serious problems.

Advantages of Using Rubber Impellers in Pumps

Rubber impellers play a significant role in pump systems, offering unique advantages. One key benefit is their excellent resilience. Rubber can flex under pressure, which helps absorb shocks. This flexibility promotes a longer service life and reduces wear. It's particularly useful in applications involving corrosive or abrasive liquids.

Another advantage is the noise reduction. Rubber impellers tend to operate more quietly than their metal counterparts. This is valuable in settings where noise control is critical. Additionally, rubber impellers can create a better seal, minimizing leaks and enhancing efficiency. However, they may not perform well in extreme temperatures, requiring careful consideration in certain environments.

Maintenance of rubber impellers can present challenges. They may require frequent inspections due to wear. Over time, exposure to chemicals might degrade the material, impacting performance. Users must balance the advantages with possible drawbacks. Considering these factors is essential for optimal operation and longevity of the pump system.

Applications and Industries Utilizing Rubber Impellers

Rubber impellers are widely used in various industries due to their unique properties. They excel in environments where chemical resistance and flexibility are essential. Common applications include wastewater treatment, chemical processing, and food manufacturing. In these sectors, rubber impellers perform efficiently, reducing wear and extending service life.

In wastewater treatment, rubber impellers handle abrasive sludge and aggressive chemicals. Their flexibility allows them to adapt to changing conditions, reducing damage. The food industry benefits from non-reactive materials, ensuring safety and quality. Moreover, rubber impellers operate quietly, minimizing noise pollution.

Tip: Regular maintenance can prevent unexpected failures. Inspect impellers for wear and replace them when necessary. Also, ensure they are compatible with the fluids they handle.

Some companies underestimate the importance of choosing the right material for impellers. A poorly made impeller can lead to significant downtime and cost. Always consider the application, environment, and fluid characteristics before making a decision.

Article Source:

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.