International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

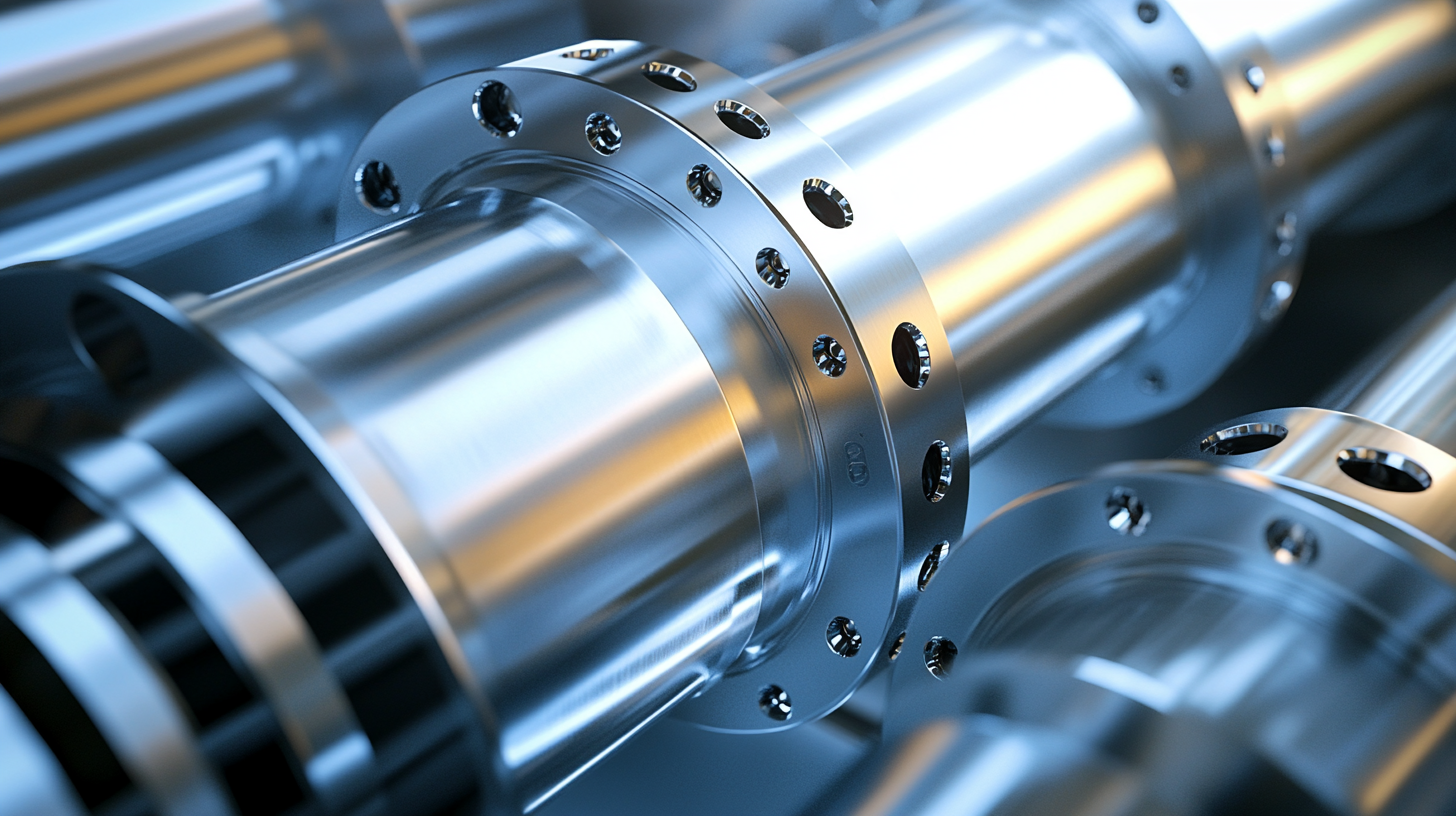

Innovative Applications of Stainless Steel Hydraulic Cylinders in Modern Machinery

The use of stainless steel hydraulic cylinders has become increasingly prevalent in modern machinery, driven by their superior resistance to corrosion, high strength-to-weight ratio, and long service life. According to a recent market report by ResearchAndMarkets, the global hydraulic cylinder market is projected to reach USD 17.6 billion by 2025, with stainless steel variants representing a significant segment due to their enhanced performance in diverse applications. This trend reflects an industry-wide shift towards more durable and efficient components that can withstand the rigors of various environments, particularly in sectors such as construction, agriculture, and marine engineering.

As the demand for high-performance machinery grows, the innovative application of stainless steel hydraulic cylinders is at the forefront of engineering advancements. With the increasing adoption of automation and advanced manufacturing processes, these cylinders are not only pivotal in enhancing operational efficiency but also in reducing maintenance costs and downtime. A report by MarketWatch indicates that the advancement in hydraulic technologies has led to improved functionality and adaptability of hydraulic systems, further solidifying the role of stainless steel hydraulic cylinders in driving the evolution of modern machinery.

The Evolution of Stainless Steel Hydraulic Cylinders in Industrial Applications

Stainless steel hydraulic cylinders have undergone significant evolution over the years, transforming from basic components to critical elements in modern industrial applications. According to a report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach USD 21.4 billion by 2026, growing at a CAGR of 5.5%. This growth reflects the increasing demand for high-performance machinery that requires dependable hydraulic systems. The transition to stainless steel in hydraulic cylinder manufacturing is a response to the need for improved corrosion resistance, durability, and longevity. Traditional materials often succumb to rust and wear, leading to costly downtime and maintenance. Stainless steel, with its inherent resistance to chemicals and harsh environments, offers a viable solution. For instance, a study by ResearchAndMarkets highlights that stainless steel cylinders provide up to 40% longer service life compared to their carbon steel counterparts, making them especially suitable for applications in marine, chemical processing, and food manufacturing industries. As technology advances, innovative designs and applications of stainless steel hydraulic cylinders are emerging. The integration of smart sensors and IoT technology allows for real-time monitoring and predictive maintenance, further enhancing their efficiency. According to a report by Grand View Research, the smart hydraulic cylinder segment is expected to witness a growth rate of over 6% from 2022 to 2030, emphasizing the importance of integrating sustainment and automation into modern machinery. This evolution not only optimizes operational performance but also significantly reduces the environmental footprint of industrial operations.

Key Advantages of Stainless Steel in Hydraulic Cylinder Design

Stainless steel hydraulic cylinders have revolutionized the design and functionality of modern machinery. One of the most significant advantages of utilizing stainless steel in hydraulic cylinder construction is its excellent resistance to corrosion. This property is particularly beneficial in environments where moisture and harsh chemicals are prevalent, such as in marine applications or industrial settings. By minimizing corrosion-related degradation, stainless steel hydraulic cylinders can maintain their structural integrity and performance over prolonged periods, leading to increased reliability and reduced maintenance costs.

In addition to corrosion resistance, stainless steel offers superior strength and durability compared to traditional materials. This means that hydraulic cylinders can withstand higher pressures and more demanding operational conditions without compromising their performance. The strength-to-weight ratio of stainless steel allows for the design of lighter yet more robust cylinders, contributing to overall weight reduction in machinery. This is crucial for enhancing efficiency and maneuverability, especially in heavy machinery applications like construction and agriculture.

Furthermore, stainless steel's aesthetic appeal and hygienic properties make it a preferred choice in applications where cleanliness is paramount, such as in food processing or pharmaceutical machinery. The smooth surface finish of stainless steel reduces the risk of contamination, ensuring that products meet strict health and safety standards. As industries continue to seek innovative solutions to improve efficiency and sustainability, the adoption of stainless steel hydraulic cylinders is set to expand, paving the way for enhanced machinery performance while adhering to modern regulatory requirements.

Innovative Technologies Enhancing Performance and Efficiency

The evolution of stainless steel hydraulic cylinders has brought about significant advancements in modern machinery, particularly through the integration of innovative technologies. These advancements have not only enhanced performance but also improved efficiency across various applications. One notable technology is the incorporation of smart sensors within hydraulic systems, which allows for real-time monitoring and diagnostics. This capability enables operators to track performance metrics and predict maintenance needs, ultimately reducing downtime and operational costs.

Furthermore, advancements in surface treatment and coatings have led to enhanced durability and resistance against corrosion. These improvements extend the lifespan of hydraulic cylinders, making them increasingly suitable for harsh environments, such as marine and industrial applications. By utilizing advanced manufacturing techniques, such as additive manufacturing, engineers can design and create hydraulic cylinders that are lighter yet stronger, thus optimizing them for high-performance tasks.

Additionally, the development of energy-efficient hydraulic systems has become a game-changer in the realm of machinery. Innovations such as variable displacement pumps and closed-loop systems allow for precise control of hydraulic flow, thus minimizing energy consumption and enhancing overall system efficiency. By leveraging these technologies, industries can achieve greater productivity while simultaneously reducing their environmental footprint, making stainless steel hydraulic cylinders an integral component of modern machinery.

Real-World Case Studies: Success Stories of Stainless Steel Cylinders

In the realm of modern machinery, stainless steel hydraulic cylinders have emerged as pivotal components, revolutionizing various industrial applications. These cylinders are renowned for their durability, resistance to corrosion, and ability to withstand high pressure, making them ideal for environments that require both reliability and strength. Recent case studies illustrate the tangible benefits and innovative applications of these hydraulic cylinders in real-world scenarios, highlighting their role in enhancing operational efficiency and safety.

One compelling example comes from the construction sector, where a leading manufacturer implemented stainless steel hydraulic cylinders in their heavy machinery. According to industry reports, the use of these cylinders reduced maintenance costs by approximately 30% while increasing the machine's lifespan by 25%. Such improvements underscore the long-term value of investing in high-quality materials that can endure harsh working conditions and contribute to overall productivity.

In another instance, a marine engineering firm adopted stainless steel hydraulic systems for underwater applications. Their research indicated that stainless steel components could survive the corrosive effects of saltwater far better than traditional materials. This decision not only improved the functionality of their equipment but also reduced downtime by 40%, showcasing how strategic choices in material selection can lead to significant operational advantages.

The innovative applications of stainless steel hydraulic cylinders extend beyond construction and marine engineering, with growing interest in their use across other sectors including agriculture and robotics. As industries continue to innovate, the demand for robust and reliable hydraulic solutions is set to surge, positioning stainless steel cylinders as a cornerstone of modern machinery advancements.

Future Trends: The Role of Stainless Steel in Next-Gen Machinery

The future of machinery is increasingly dependent on advanced materials, with stainless steel emerging as a key player in next-gen equipment design and implementation. As manufacturing processes evolve, the demand for durable and corrosion-resistant components has surged. According to the latest reports, the North America Sheet Metal Fabrication Equipment Market is projected to experience significant growth by 2030, driven by innovations in cutting and shearing technology that utilize stainless steel effectively. The unmatched strength and longevity of stainless steel hydraulic cylinders make them ideal for supporting complex machinery operations, ensuring heightened efficiency and reliability.

Moreover, the integration of Industrial Internet of Things (IIoT) technologies into manufacturing processes is radically transforming how machinery operates. Companies like Arrowhead Systems are leveraging IIoT tools for machine condition monitoring, facilitating real-time diagnostics that optimize operational performance. This trend aligns with the broader movement toward automation and advanced controls, which are also critical in the design of contemporary packaging machinery. The incorporation of stainless steel in these applications not only enhances durability but also supports the hygiene standards increasingly demanded in industries such as pharma and biopharma, which are rapidly pivoting towards biologics and complex therapies.

In summary, as the market for grain silos and ancillary equipment evolves, the role of stainless steel is paramount in developing machinery that meets emerging demands. The advancements in control technologies and automation demonstrate a clear trajectory toward future innovations where stainless steel hydraulic cylinders will play an indispensable role in driving machinery efficiency, safety, and performance across several sectors.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.